GERMANY Klaus Longmuss

Wood-Mizer Sägewerke GmbH

Dorfstraße 5, 29485 Schletau

Tel.: +49-5883-9880-10

Fax: +49-5883-9880-20

Klaus Longmuss

Tel.: +49-5883-9880-12

GSM: +49-17-298-55-892

Subagent:

SWEDEN Kjell Larsson

Mekwood AB

Slingan 14, 812 41 Gästrike-Hammarby

Tel.: +46-290-515-65

Kjell Larsson

GSM: +46-706-797-965

IRELAND

Wood-Mizer Ireland

Stephen Brennan

Cum Lahardane Ballina County Mayo

Tel:+353 96 51345

Subagents:

DENMARK Brian Jensen

Arnborgvej 9, 7330 Brande- Fasterholt

Tel.: +45-971-88-265

Fax: +45-971-88-266

Brian Jensen

GSM: +45-23-49-5828

ROMANIA Adrian Echert

SC WOOD-MIZER RO SRL

TRANSILVANIEI Nr. 5

Sibiu, Cisnadie 555300

Tel.:/Fax: : +40-369-405-433

GSM: +40-745-707-323

Regional Manager - Asia

Robert Moxham

Regional Direction - Asia

Wood-Mizer Asia Manufacturing Co., Ltd.

No.2, Gongyequ 40th Rd. Xitun District,

Taichung City, 40768, Taiwan, R.O.C.

TEL: +886-4-2359 3022

FAX: +886-4-2359 3205

CELL: +886-9-0568 7708

www.woodmizerasia.com

Skype: r.g.moxham

Netherlands Chris Dragt

Lange Brink 77d,

7317 BD Apeldoorn

Tel.: +31-55312-1833

Fax: +31-55312-2042

Subagent:

ROMANIA M. Echert

S.C. Echert Comprod s.r.l

Str. Schitului Nr. 6, Apt.7 etajul-1

725 70 Vatra Dornei, Romania

Tel.:/Fax: +40-230-374-235

Tel. : +40-740-35-35-74

Regional Manager - Africa

Gavin Prowse

Regional Sales Director - Africa

Wood-Mizer Africa (Pty) Ltd.

Unit 1,Leader Park

20 Chariot Street

Stormill Ext.5

Maraisburg, Johannesburg

South Africa

TEL: +27 11 473 1313

FAX: +27 11 473 2005

CELL: +27 71 398 8010

EMAIL: gprowse@woodmizer.com

www.woodmizerafrica.com

Skype: gavin.prowse

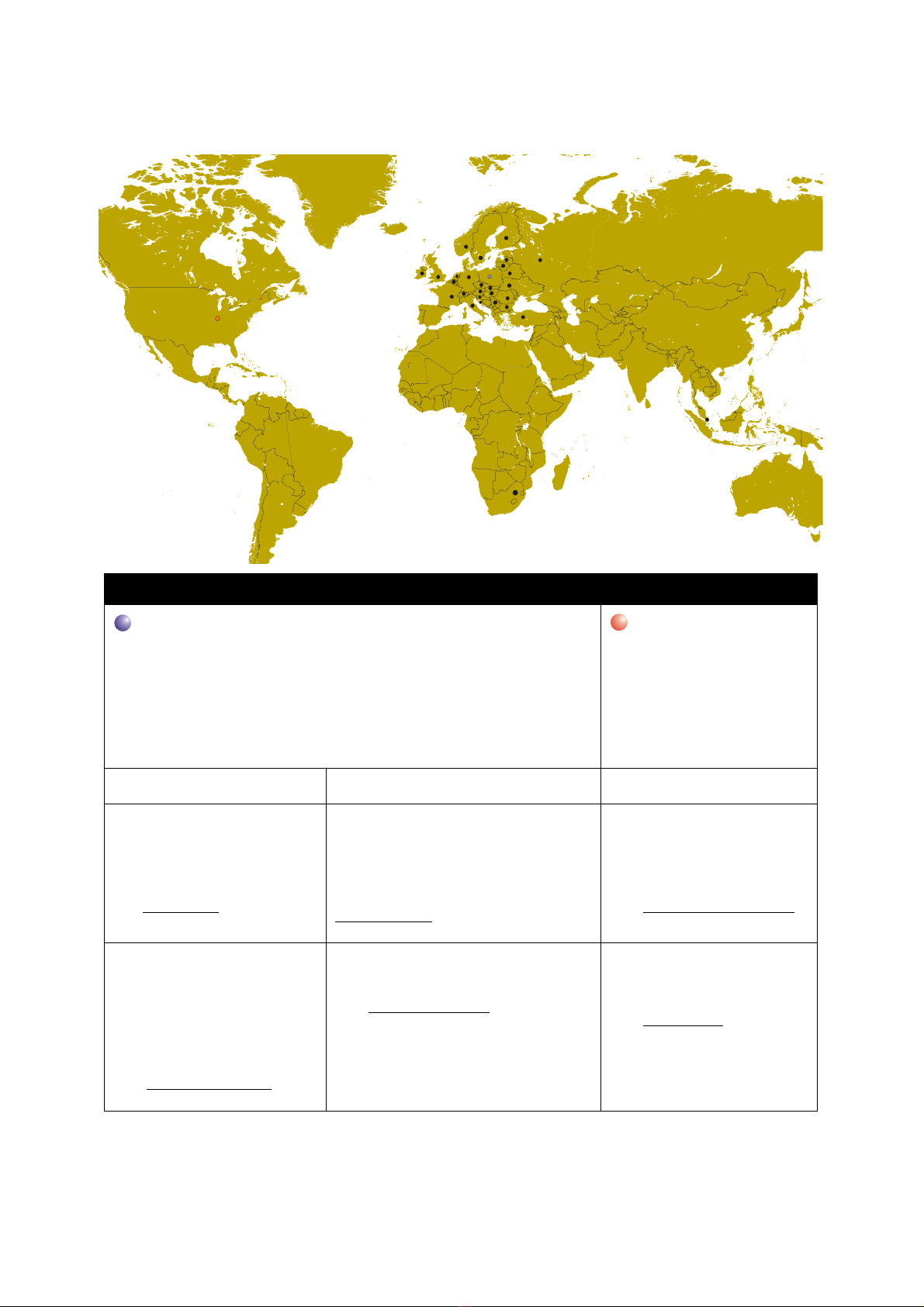

USA World Headquarters Canadian Headquarters

Serving North & South America, Oceania, East Asia

Wood-Mizer LLC

8180 West 10th Street

Indianapolis, IN 46214

Phone: 317.271.1542 or 800.553.0182

Customer Service: 800.525.8100

Fax: 317.273.1011

Email: infocenter@woodmizer.com

Serving Canada

Wood-Mizer Canada

396 County Road 36, Unit B

Lindsay, ON K9V 4R3

Phone: 705.878.5255 or 877.357.3373

Fax: 705.878.5355

Email: ContactCanada@woodmizer.com

Brazil Headquarters Europe Headquarters

Serving Brazil

Wood-Mizer do Brasil

Rua Dom Pedro 1, No: 205 Bairro: Sao Jose

Ivoti/RS CEP:93.900-000

Tel: +55 51 9894-6461/ +55 21 8030-3338/ +55 51 3563-4784

Email: info@woodmizer.com.br

Serving Europe, Africa, West Asia

Wood-Mizer Industries Sp z o.o.

Nagorna 114

62-600 Kolo, Poland

Phone: +48.63.26.26.000

Fax: +48.63.27.22.327

Branches & Authorized Sales Centers

For a complete list of dealers, visit www.woodmizer.com