Page 6of 7

SECTION 3 - Running the Kiln

3.1 To Start the Firing

It is advised that you always turn the Kiln OFF and then back ON between or after each firing. This

resets the controller so it knows to begin a new firing and ensures it does not become confused.

To begin Firing Press the square RED Start Button.

The “Cycle End” light will turn off.

The controller will indicate that the kiln elements are being turned on by illumination of a small

square red indicator light (marked OP1) in the top right hand corner of the controller.

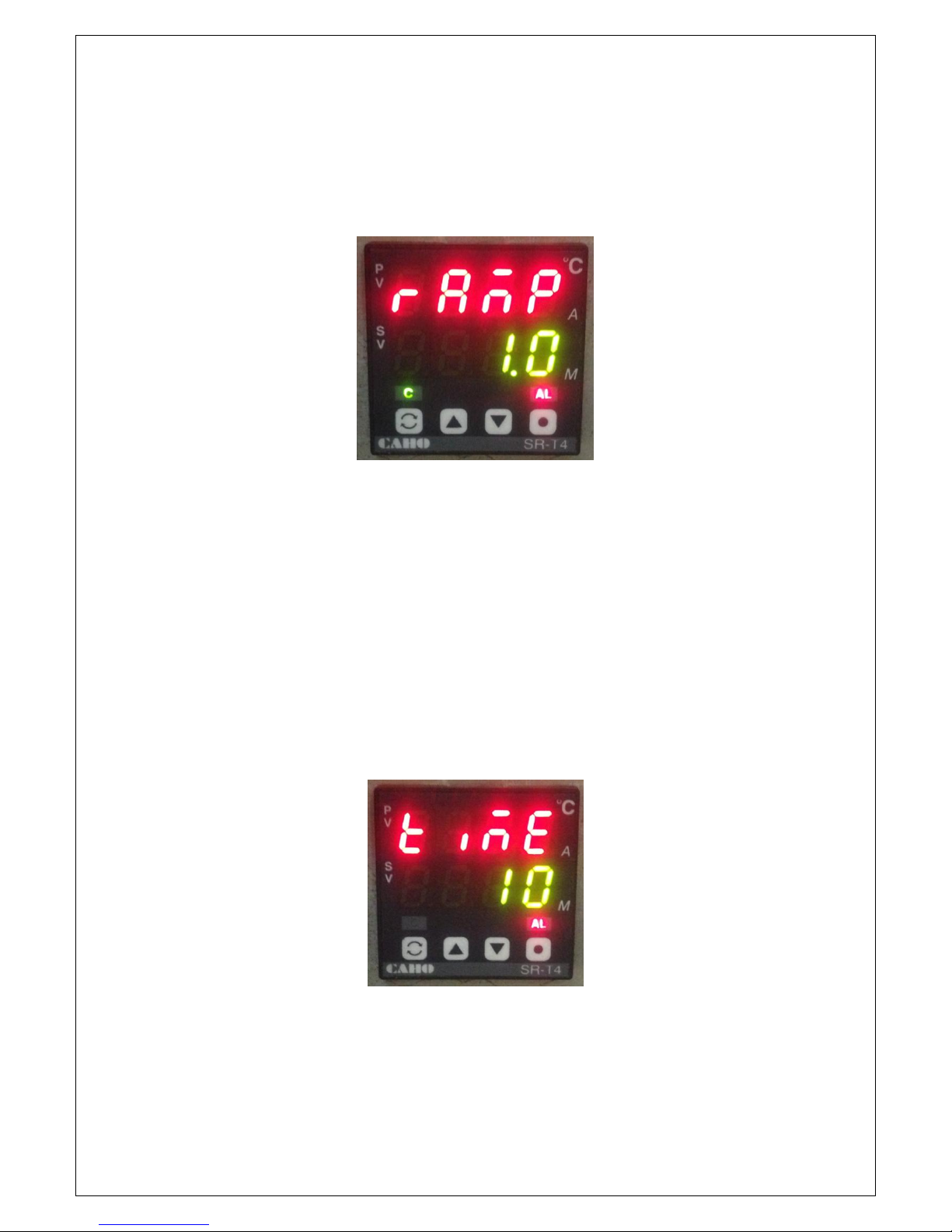

The bottom display will start to indicate the theoretical target temperature which the kiln

chamber should be at any point during the programmed firing. Visual checking of the bottom

theoretical program display with the top actual process value display will be helpful to the operator

to ensure that the kiln is able to keep up with the program.

NOTE: The Kiln will not always show the PV and SV being equal. The Controller will attempt to

keep these values being equal but may lag or overshoot from time to time. This is the normal

function of the controller. If these do become separated by a large amount you may have an issue

with the Kiln not being able to keep up with the program or there may be a problem with the Kiln.

3.2 Completion of Firing

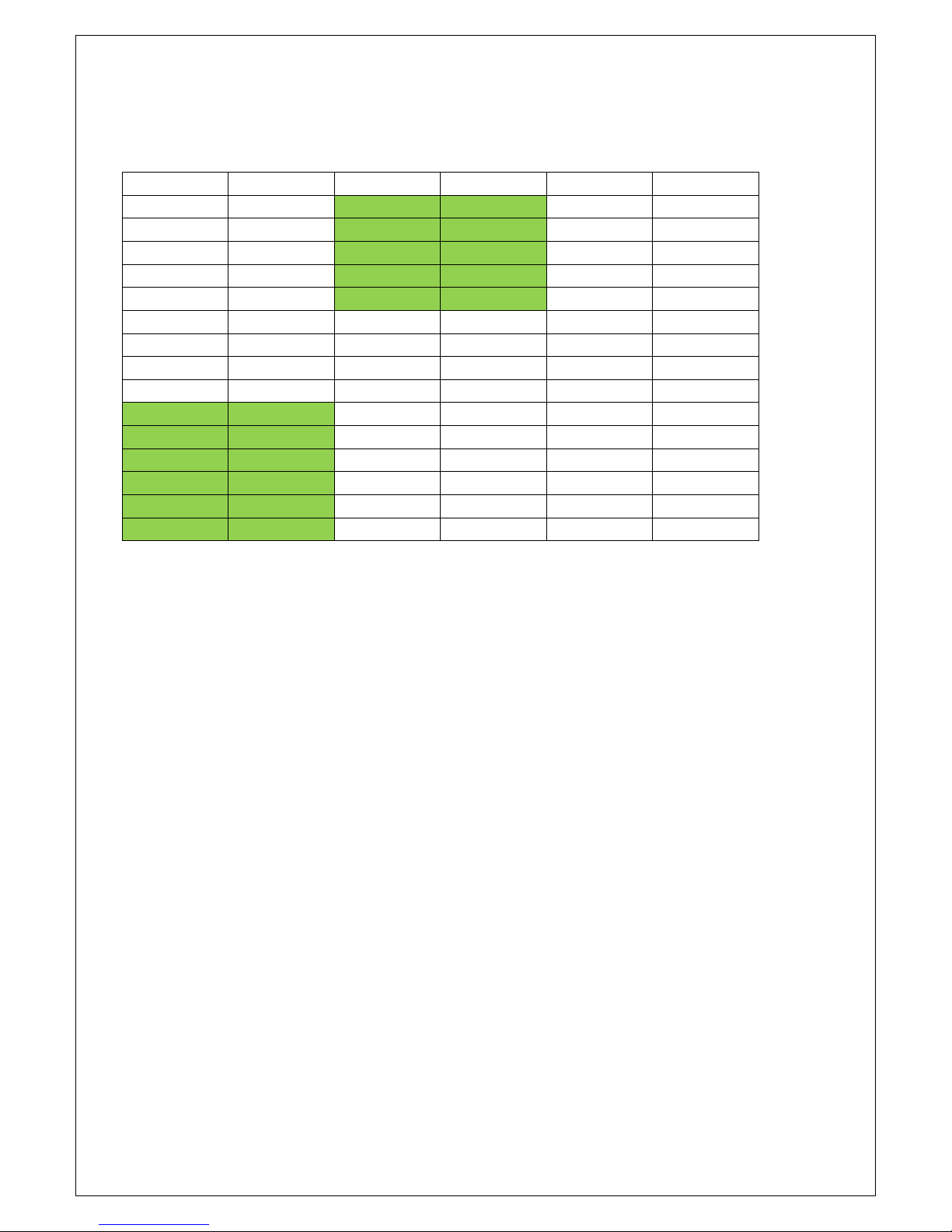

At the moment that the kiln reaches the set value (set temperature) both the top display and the

bottom display will show this value at the same time. The program has now moved into the “timed

soak” stage of the program. When the “timed Soak” period has been completed, the small red

alarm light and the END light will be ON. The Kiln will now “Turn Off” as the firing is now

completed and the kiln temperature will begin to fall. The top display will continue to display the

falling temperature and the bottom section will display the set temperature that the Kiln reached.