1. INTRODUCTION

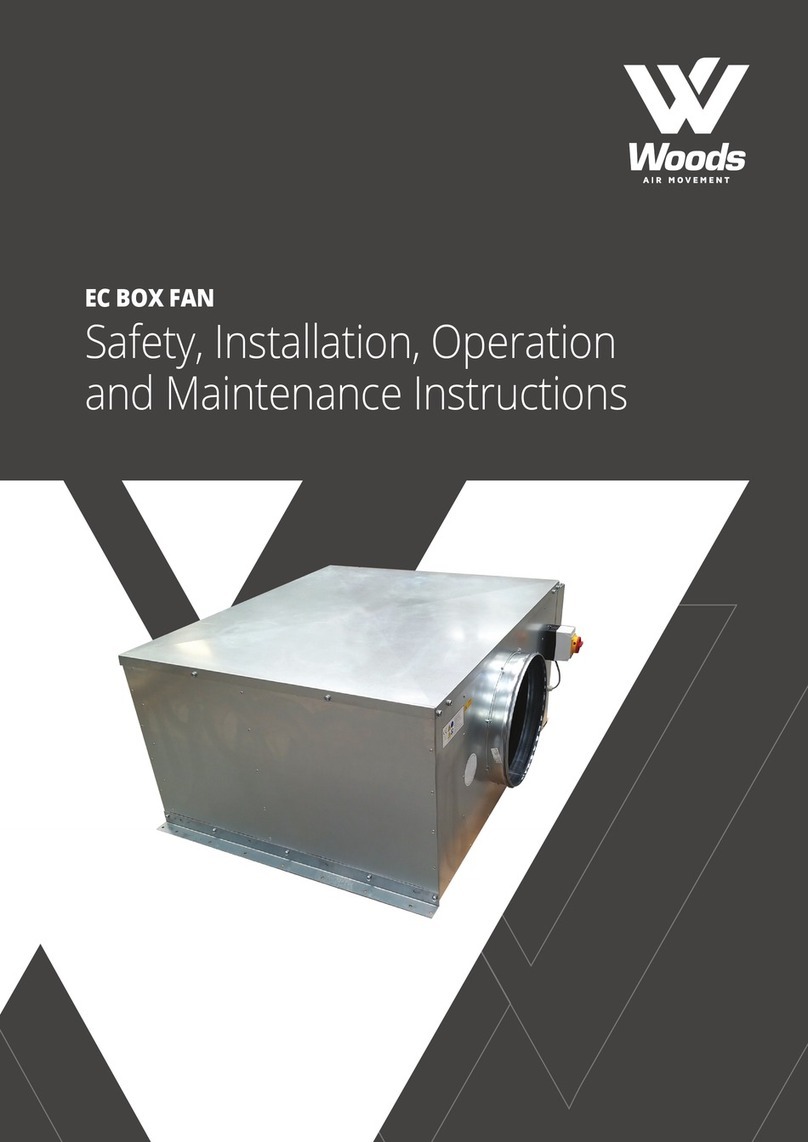

Designed for internal applications, the Woods EC Twin & Single box fan range encompasses models of direct driven

centrifugal fan units with airow duties up to 3.5m3/s. Not suitable for outdoor applications.

Motor windings are tted with an auto-reset thermal cut-out.

Motors are pre-wired to an external terminal box speed controller, auto-changeover & isolator.

2. GENERAL CONSTRUCTION

Casework is manufactured from 0.9mm to 1.2mm thick galvanised sheet steel with an ‘O’ class foam / barrier mat

insulation to provide acoustic insulation. Access is via a removable top cover. Fitted backdraught shutters prevent

recirculation via inoperative fan.

Discharge via optional bird-mesh protected cowl.

3. INSPECTION UPON RECEIPT OF GOODS

Immediately upon receipt of any goods, a careful inspection should be undertaken to ensure neither damage has

occurred nor parts missing.

Particular attention should be paid to the fan impeller, motor shaft, anti-vibration mounts, exible connection, coil

connection & casework.

In the event of such damage or loss having occurred, inform supplier WITHIN 3 WORKING DAYS of the delivery

date, giving the serial number which can be found on the nameplate. After this period we will be unable to

entertain any claim for loss or damage.

4. HANDLING

Units being craned into position must be handled with care to avoid damage.

5. INSTALLATION

When installing our equipment, the following instructions below must be observed.

6. SAFETY

It is the responsibility of the installer to ensure that the installation complies with the legal regulations and the

current HEALTH AND SAFETY AT WORK ACT.

7. AMBIENT TEMPERATURES

The range of units covered by this manual are designed for use in an environment where the ambient air

temperature is unlikely to exceed 50oC.

8. MOUNTING

These units must be mounted in the horizontal plane. Bottom access can be accommodated if advised at time

of order. These fans are not suitable for inverted mounting on to the ceiling.

CONTENTS PAGE

1. INTRODUCTION ............................................................................................................................................................ 3

2. GENERAL CONSTRUCTION .......................................................................................................................................... 3

3. INSPECTION UPON RECEIPT OF GOODS ................................................................................................................... 3

4. HANDLING ..................................................................................................................................................................... 3

5. INSTALLATION .............................................................................................................................................................. 3

6. SAFETY ........................................................................................................................................................................... 3

7. AMBIENT TEMPERATURES .......................................................................................................................................... 3

8. MOUNTING ................................................................................................................................................................... 3

9. POSITIONING ................................................................................................................................................................ 4

10. DUCT CONNECTIONS ................................................................................................................................................... 4

11. ACCESS ........................................................................................................................................................................... 4

12. ELECTRICAL WIRING ..................................................................................................................................................... 4

13. MAINTENANCE .............................................................................................................................................................. 4

14. FAN WIRING ................................................................................................................................................................... 5

15. CONTROLS FUNCTIONALITY ....................................................................................................................................... 6

16. GENERAL DESCRIPTION ............................................................................................................................................... 6

17. INSTALLATION .............................................................................................................................................................. 6

18. OPERATION ................................................................................................................................................................... 6

18.1 DIAGNOSTIC ........................................................................................................................................................... 6

18.2 RUN MODES ........................................................................................................................................................... 7

18.3 FAN SPEED CONTROL ............................................................................................................................................ 7

18.4 BMS ......................................................................................................................................................................... 7

19. LED’S ............................................................................................................................................................................... 7

20. TEST MODE .................................................................................................................................................................... 7

21. DECLARATION CERTIFICATE ....................................................................................................................................... 8

32