-3-

M1042/M1045 3-in-1 Sheet Metal Machine

INTRODUCTION

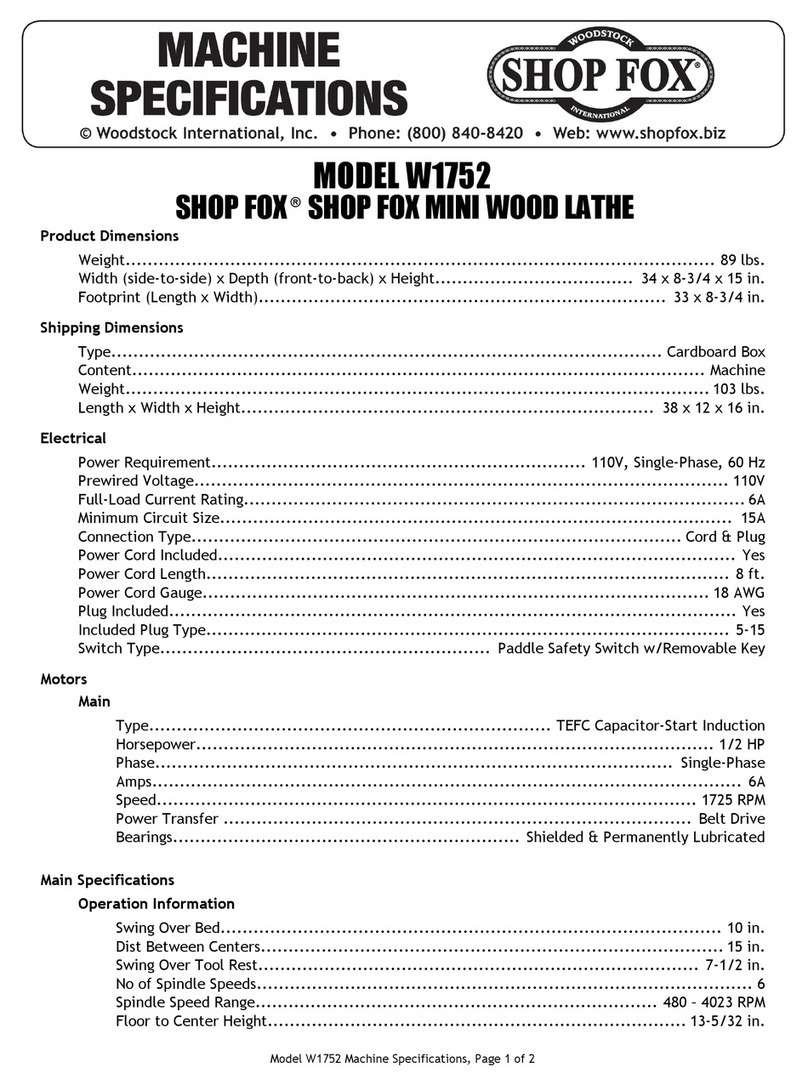

Specifications

M1042 Specifications

Height (With Handle in Center Position) ......................................................30"

Footprint .............................................................................. 141⁄2" x 321⁄2"

Crate Size .................................................................... 39" L x 18" W x 26" H

Box Finger Size .......................................................... 10", 4"(x2), 3", 2", & 1"

Wire Groove Sizes ..................................... 5⁄32"(4mm), 11⁄64"(4.5mm), 7⁄32"(5.5mm)

Rollers ................................................................. 11⁄2" Dia. 22 Ga. Mild Steel

Brake .........................................................................24", 22 Ga. Mild Steel

Shear .........................................................................24", 28 Ga. Mild Steel

Work Stop Range (Front) ...............................................1⁄2"-16" (12.7mm-406mm)

Work Stop Range (Rear) ...............................................1⁄2"-16" (12.7mm-406mm)

Roller Construction ....................................................... Precision Ground Steel

Shear Blade Construction ................................................................Tool Steel

Brake .............................................................................................Steel

Frame ........................................................................................Cast Iron

Table ................................................................... Precision Ground Cast Iron

Shipping Weight ............................................................................. 341 lbs.

Machine Weight ............................................................................. 325 lbs.

M1045 Specifications

Height (With Handle in Center Position) ...................................................... 23"

Footprint ...............................................................................141⁄2" x 111⁄2"

Crate Size .................................................................... 23" L x 14" W x 17" H

Finger Sizes .......................................................................1", 2" (x2), 3", 4"

Wire Groove Sizes ......................................... 3⁄32", 1⁄8", 5⁄32", 3⁄16", 7⁄32", and 1⁄4"

Rollers ................................................................. 11⁄2" Dia. 22 Ga. Mild Steel

Brake .........................................................................12", 22 Ga. Mild Steel

Shear .........................................................................12", 28 Ga. Mild Steel

Work Stop Range (Front) ................................................1⁄2"-9" (12.7mm-406mm)

Work Stop Range (Rear) ................................................1⁄2"-9" (12.7mm-406mm)

Roller Construction ....................................................... Precision Ground Steel

Shear Blade Construction ................................................................Tool Steel

Brake .............................................................................................Steel

Frame ........................................................................................Cast Iron

Table ................................................................... Precision Ground Cast Iron

Shipping Weight ............................................................................. 120 lbs.

Machine Weight ............................................................................. 110 lbs.