~.

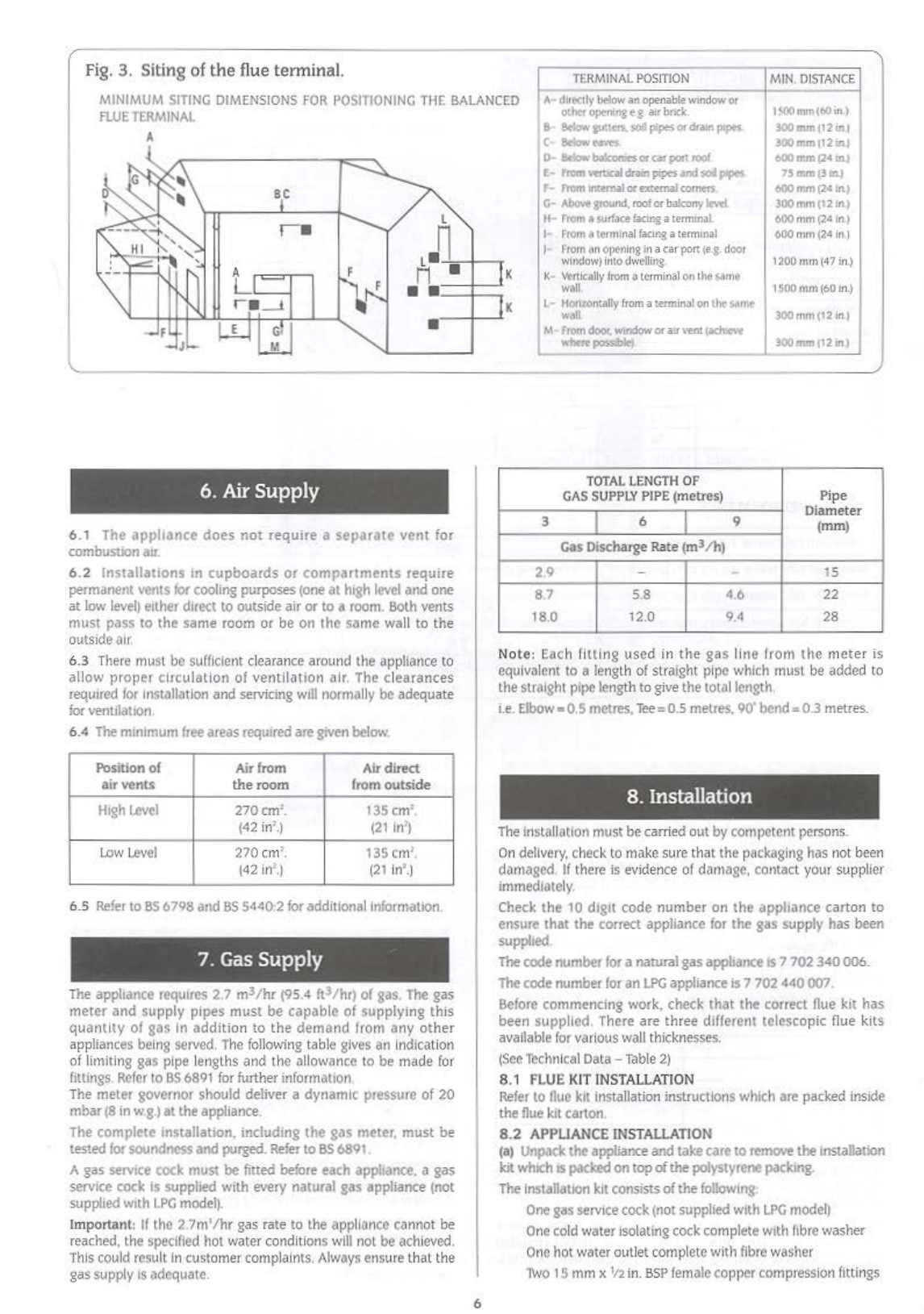

3. Siting of the

fl

ue

terminal.

I

~INIMUM

SITING

DIMENSIONS

FOR

POSITIONING

THE

BAlANCED

FlUE

TERMINAl

I

TERMINAl

POSITION

r

A•

dI!eelly

below

an

Openab!e

WlndO'.V

Or

othtt

opeoni"'i

t g

air

bnck.

a

Bt~oY.·

tLJUffl.

soil

pipes

or

dra:il'l

ptpes

c

..

Bciowe.r.n

MIN.

D

ISTAN

CE

1<.00mm(60.rt)

JOO

mm

1121tlJ

JOO

mm

112lll.J

600mmt24

tnJ

7Smm(311l.)

600

mm

(24

tn.J

300

mm

(121n.)

600mm(2.4

in)

600mm(2,d

in)

A

6.

Air

Supply

6.1 The appliance

does

not

require a

separate

vent

for

combustion

atr.

6.2

lns1allatlons

on

cupboards

or

compartments require

permanent vents

for

cooling purposes

(one

at high

level

and one

at

low

level)

either dtrect

to

outside air or

to

a

room.

Both

vents

must pass to the same room or be on the same wall

to

the

o

utside

air.

6.3

There must

be

sufficie

nt clearance around the appliance

to

allow proper circula

ti

on of

ventil~tlon

air. The cl

ea

ra

nces

required

for

Installation and servicing

will

normally beadequate

for

ventilation

6.4

The

mmlmum

free

areas required aregiven

below.

Position of

Air

from

Air

direct

air

vents the

room

from

outside

H1gh

Level

270cm'. t35 em'.

(42

in

'.)

121

ln'J

low

Level

270

cm

'. 135 em'.

(42

in

'.)

(21

in

'

.)

6.5

Refer

to

BS

6798 and

SS

5440:2

for

additional

Information.

7.

Gas

Supply

The appilance requires 2.7

m3

fh

r

(95.4

ft3fhr) of

gas.

The

gas

meter

and

supply pipes must be capable of supplyi

ng

this

quantity of gas in addition to

the

demand

from

a

ny

other

appliances

being

~rved.

T

he

fo

llowin

g table

gives

an

In

dica

tion

of

limiting

gas

pipe

lengths and the allowance

to

be made

for

fittings

Refer

10

BS

6891

fo

rfurther

in

for

mation

The meier governor should deliver a dynamic pressure of 20

mbar

(8

in

w.g.)at the appliance.

The complete tnstallallon. includtng

the

gas meter, must be

tested lorsoundnessand purged.

Refer

to

BS

6891

.

Agas servtce cock must be fitted

before

each apphance. a gas

service cock

Is

supplied with every natural gas appliance (not

supplied

w1th

LPG

model).

Important: If the 2

7m'/h

r gas

ra

te to

th

e app

li

ance

ca

n

no

t

be

reached.

th

e specified hot water condi

ti

ons

will

not beachieved.

This

could

resu

lt In customer complaints.

Always

ensu

re

that the

ga

s supply

IS

adequate.

6

o-

Wow

blkonlrs

or

c.lr

port

,oo{

E-

'-wrtr.oldr.wlpip<sandsol~

r-

from

lnlemal

or

external

comers

G-

Aboo.'t

around.

roof

0!

bakony

leo.'d

Jl

...

From

a

$Urface

facu-.g:a

termmill.

I

F'rom

~termina

l

facing

a

termmal

J

f'rom

M

opel'l

ing

tna

(ar

port

(e

.

.g.

door

window)

in

to

dwe-lling

K-

~rUclll

l

y

!rom

It

terminal

on

the

same

wall

L-

uonz.ontally

from

a:enninal

on

the

'l.~rnt

W.tll

M

From

door.

w~~Miow

or

a:r

\'ffit

1iC.h~

~-

..

po$$ibl<l

TOTAl

LENGTH

OF

GAS

SUPPLY

PIPE

(metres)

3 I 6 I 9

Gas Discharge Rate (ml/h)

2.9 -

..

8.7 5.8 4.6

18.0

12.0

9.4

1200m

m

(47i

n.

)

1SODmm(60in.)

300mm(12

in)

J00mm(12n)

Pipe

Diameter

(mm)

15

22

28

No

te

:

Eac

h filli

ng

used in the

gas

line from the meter is

equivalent

to

a

le

ngth of straight p

ip

e

which

must

be

added

to

th

estraight

pipe

le

ngth to

give

the towIlength.

i.e.

Elbow

• 0.5 metres,

Tee=O.S

metres. 90' bend=0.3 metres.

8. Installation

T

he

insta

ll

ation must becarri

ed

o

ut

by

competentpersons.

On

delivery,

check

to

make

su

re that the packaging has not

been

damaged

If

there

is

evidence

of

damage. contact your supplier

immediately

Check

the

10

dtgtt code number on

the

appliance carton to

ensure that the correct appliance

for

the gas supply has been

supplied

Thecode number

for

a naturalgasappliance

IS

7702 340

006.

The

code number

for

an

LPG

appliance

is

7702 440 007.

Before

commencing work. check that the correct

flue

kit

has

been supplied. There are three different telescopic flue kits

available forvarious

wall

thickne

sses.

(Sec

Thchn

l

ca

l

Data-

"lllbie

2)

8.1

FLUE

KITINST

AL

LA

TION

Refer

to

Oue

kit

in

stallation instructions

which

are packed inside

the nue

kit

carton.

8.2

APPLIANCE

INSTALLATION

(a)

Unpack

the applianceand takecare

to

remove

themstallation

kit

which

IS

packed

ontopofthe polystyrene

packmg.

The

installation

kit

consistsofthe

followmg

One

gas

serv1ce

cock

(not

supp

li

ed

wtth

LPG

model)

One

co

ld

water

iso

lating

cock

co

mplete

with

ftbre

washer

One

hot water outlet complete with

fibre

washer

1\No

15 mmx

'12

in.

SS

P

female

copper

com

press

ion

fittings