10 3730 E. SOUTHERN AVE., PHOENIX, AZ 85040 | USA

ASSEMBLY

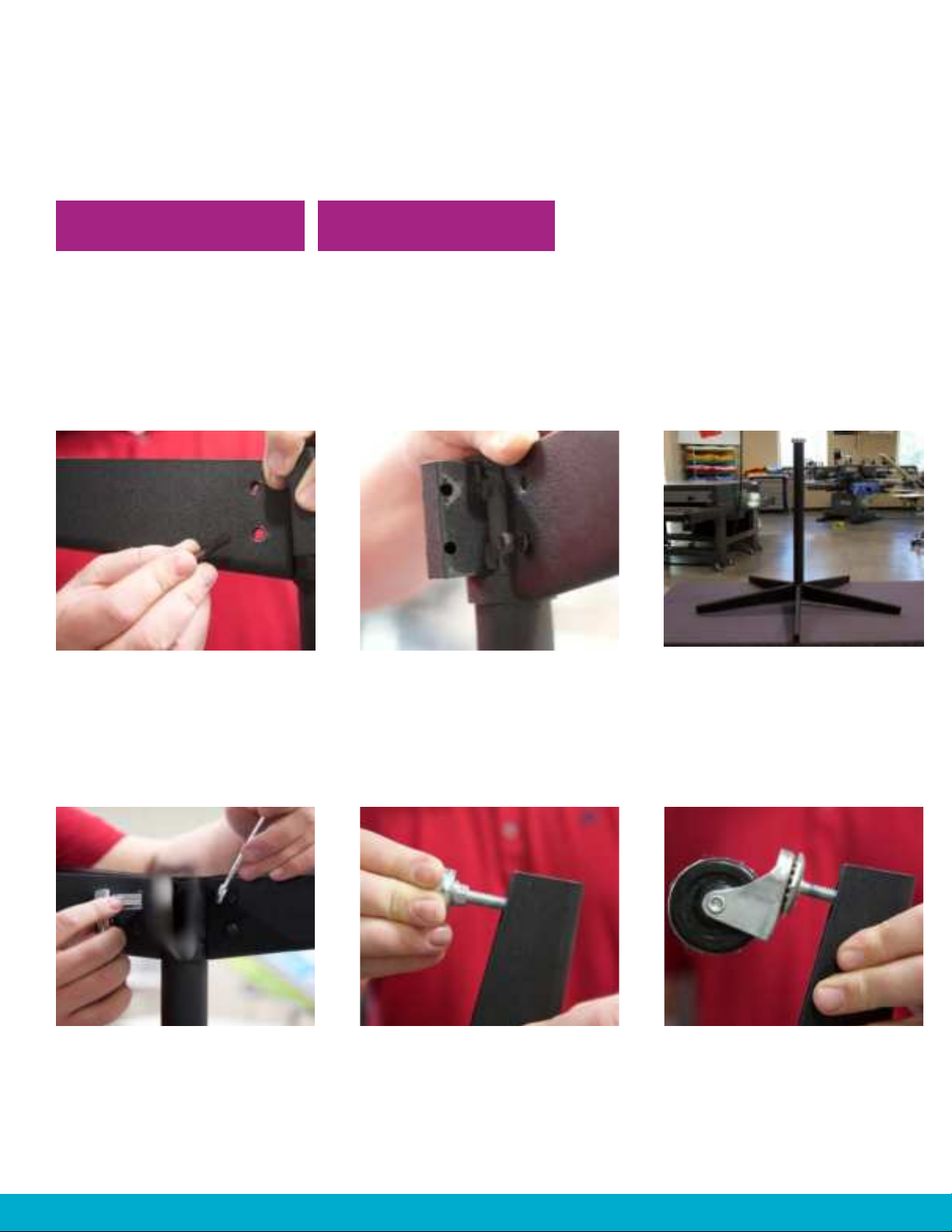

STEP 4: INSTALLING REFLECTOR SKIRTS

TOOLS NEEDED PARTS NEEDED

11 x Screws

3 x Reflector Skirts

•

•

Phillips Head

Screwdriver

Start with the middle

reflective skirt, place

it against the heating

element and align the holes

of the skirt with the holes

of the element.

With the middle skirt and

side skirt attached, thread

the screw at the front

bottom corner.

For the middle skirt, thread

the middle screw first. This

allows for room to adjust if

needed. Thread the other

two screws into the top of

the skirt.

Place the third skirt onto

the other side. Repeat

steps 3 and 4.

Place the second skirt on

either side of the element.

First, thread the screw at the

end in order to leave room

for adjustments. Thread the

other two screws into the

top of the skirt.

•

1.

4.

2.

5.

3.