4

GB

errors made in following the safety regulations and

instructions may result in an electric shock, fire and/or

serious injury.

Keep all safety regulations and instructions in a

safe place for future use.

Protect yourself and your environment from risks and

accidents by taking the appropriate precautionary

measures.

Residual risks

Even if you use the equipment in accordance with the

instructions, certain residual risks cannot be eliminated.

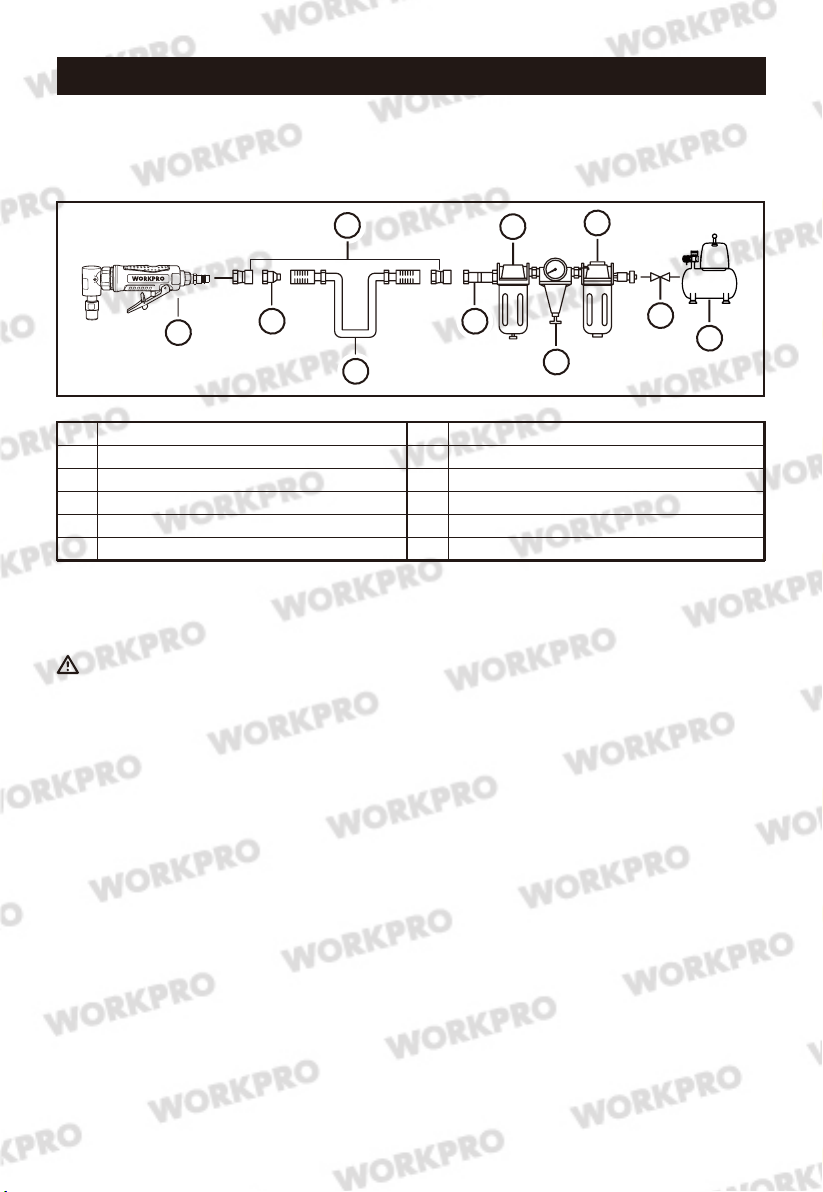

2. Layout and Unpacking

2.1 Layout (Fig. 1)

1. Clamp nut

2. Clamps (3mm, 6mm)

3. Clamp holder

4. Operating switch

5. Safety lock-off

6. Compressed air connection

7. Lubricant

8. Chuck key, 11.5 mm

9. Chuck key, 17 mm

2.2 Items supplied

Carefully remove the tool and accessories from the

box. Make sure that all items listed in the packing list

are included. Inspect the tool carefully to make sure no

breakage or damage occurred during shipping. Do not

discard the packing material until you have carefully

inspected and satisfactorily operated the tool.

This package contains:

Clamp (one installed and one replacement)

Compressed air connection

Lubricant

Chuck key:11.5mm,17mm

Operating instruction

Check for damage to the tool, parts or accessories

which may have occurred during transport. Take the

time to thoroughly read and understand this manual

prior to operation.

Danger!

The equipment and packaging material are not

toys. Do not let children play with plastic bags, foils

or small parts. There is a danger of swallowing or

suffocating!

Danger!

When using the equipment, a few safety precautions

must be observed to avoid injuries and damage.

Please read the complete operating instructions and

safety regulations with due care. Keep this manual in a

safe place, so that the information is available at all

times. If you give the equipment to any other person,

hand over these operating instructions and safety

regulations as well. We cannot accept any liability for

damage or accidents which arise due to a failure to

follow these instructions and the safety instructions.

1. Safety regulations

KEEP CHILDREN, VISITORS AND BYSTANDERS

AWAY FROM TOOL. Distractions can cause misuse

and possible loss of control. When tool is not

operational it should be locked in a safe place out of

the reach of children.

USE SAFETY GLASSES AND EAR PROTECTION:

Air tool operators and others in work area should

always wear safety glasses and ear protection to

prevent injury from flying debris as well as possible

hearing damage.

NEVER USE OXYGEN, COMBUSTIBLE OR ANY

OTHER BOTTLED GAS as a power source or it can

cause an explosion and serious personal injury.

DO NOT CONNECT TOOL TO COMPRESSED AIR

THAT EXCEEDS 120PSI.

MAKE SURE HOSE IS FREE OF ANY OBSTRUC-

TIONS OR SNAGS. Entangled hoses can cause loss

of balance or footing.

KEEP THE TOOL POINTED AWAY FROM YOUR-

SELF and others at all times and keep hands, any

body parts away from rear area to safety guard

against possible injury.

DISCONNECT TOOL FROM AIR SUPPLY

BEFORE LOADING FASTENERS to prevent

accidental firing during connection.

DISCONNECT TOOL FROM AIR SUPPLY HOSE

and close the compressor before performing

maintenance and during non-operation.

DO NOT OVERREACH DURING USAGE. Maintain

proper footing at all times to avoid loss of balance

and possible injury.

NEVER USE A TOOL THAT IS LEAKING AIR, HAS

MISSING OR DAMAGED PARTSOR REQUIRES

REPAIR. and make sure all the screws are securely

tightened.

ALWAYS OPERATE TOOL IN CLEAN WELL LIT

AREAS. Be sure the work area is dear of any debris.

ONLY USE PARTS AND ACCESSORIES recommend

by manufacturer.

Danger!

Read all safety regulations and instructions. Any