Determining Liquid Level

Liquid level must be checked at regular intervals – refrigeration depends on the presence of liquid nitrogen. The liquid

level in the container can be determined with a dipstick. Insert the dipstick vertically into the container so that it rests on

the canister indexing device on the bottom of the unit. After 5 to 10 seconds, withdraw the dipstick and wave it back

and forth in the air. A frost line will form representing the depth of liquid in the container. The frost line will typically be

u-shaped; read the bottom of the u-shaped line to determine liquid level.

WARNING

Never use a hollow rod or tube as a measuring rod. When a warm

tube is inserted into liquid nitrogen, liquid will exit from the top of the

tube and may cause personal injury.

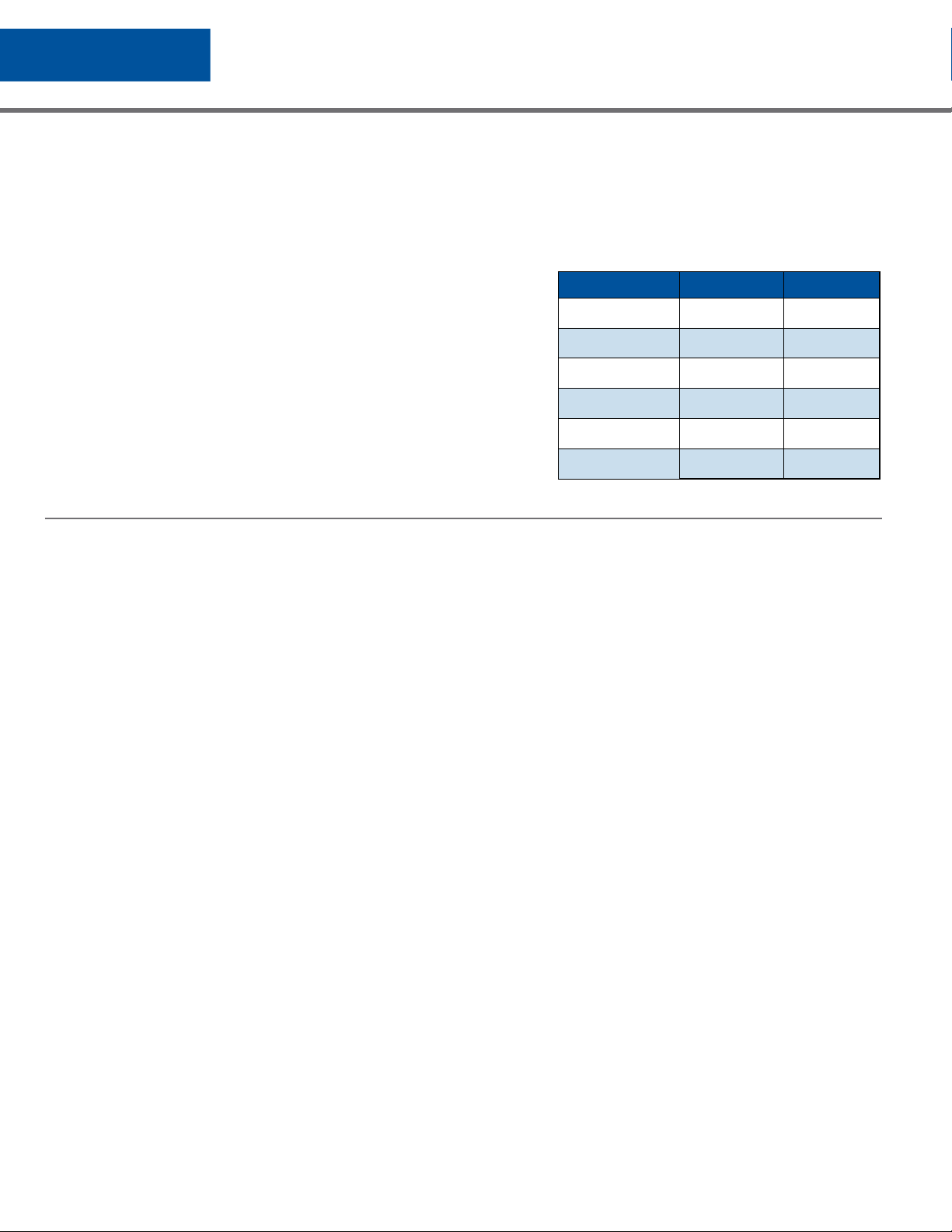

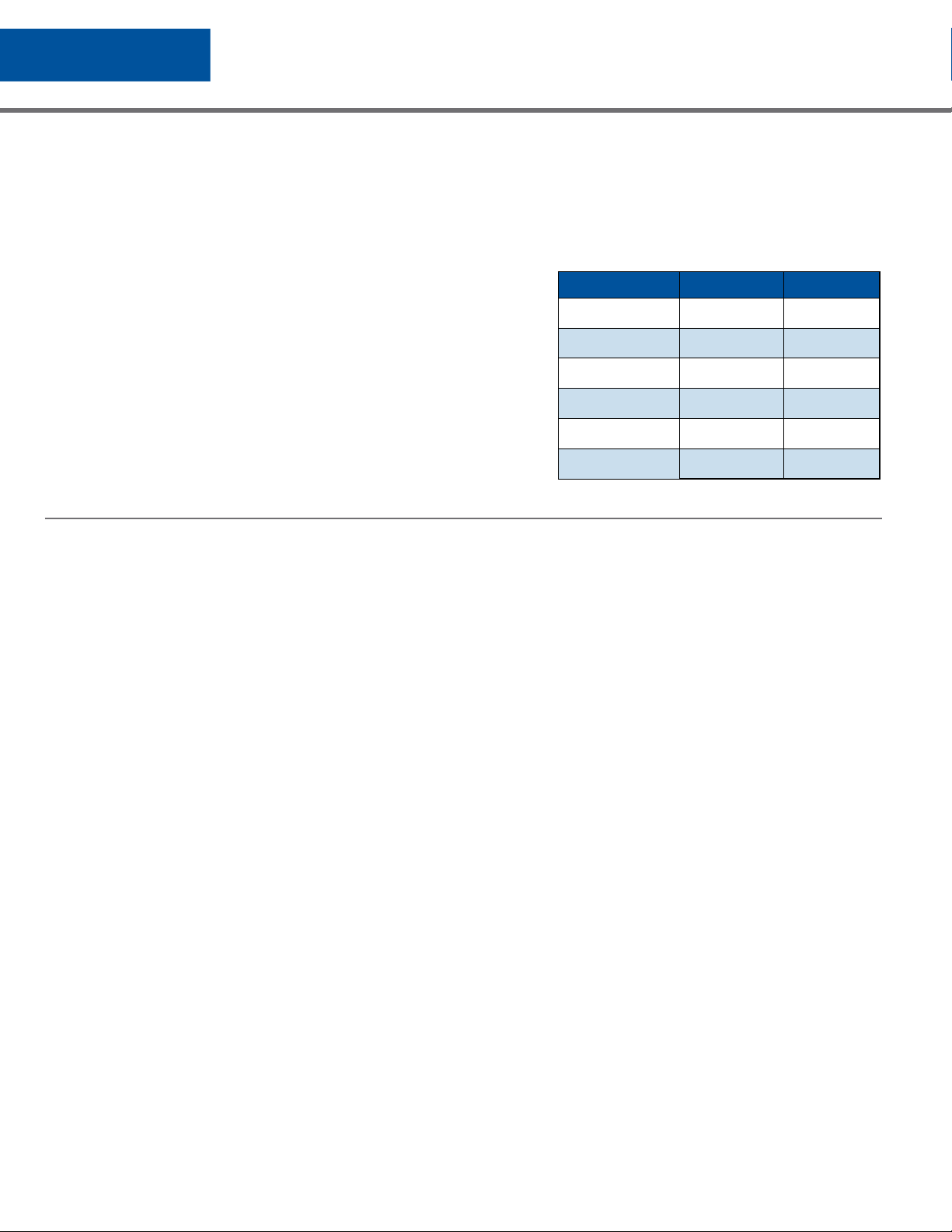

The liquid level chart shows volume of liquid nitrogen vs. depth for

LD Series Dewars. These values are approximate and are based on

standard conditions.

Routine Care & Maintenance

If ice build-up interferes with normal operation of the Dewar, the unit should be emptied and thawed. To thaw the unit,

pour out the liquid, disposing of it out-of-doors where the cold liquid will not damage driveways and other surfaces.

Warm the Dewar by purging it with air even after the Dewar has warmed to room temperature to evaporate any

collected moisture. When the Dewar is ice-free and dry, rinse the inner vessel with household bleach. Wash the inner

vessel with a 40 to 1 ratio of water to laundry detergent solution. Rinse and dry inside and out thoroughly before

placing the Dewar back into service. Do not use sharp instruments to chip ice; permanent damage to the Dewar could

result. DO NOT attempt to fasten any device to the Dewar. Welding, brazing, or piercing of the Dewar in any manner

will cause permanent damage and void the limited warranty.

Check liquid levels regularly. If high evaporation rates are apparent under normal operating conditions, the

Dewar may be losing its vacuum. Sweating and the formation of frost or ice on the outer casing are indications that the

Dewar may be losing its vacuum. Sweating or freezing of the outside casing are definite indications that the insulation

integrity may have been compromised.

If these conditions persist, contact your supplier or Worthington’s Customer Service Department at 844-273-7517 /

+1 614-438-7968 or e-mail us at customerservice@worthingtonindustries.com for information on how to conduct a

normal evaporation rate (NER) test in the field.

MODEL LITERS/INCH LITERS/CM

LD4 0.40 0.16

LD5 0.43 0.17

LD10 0.76 0.30

LD25 1.56 0.62

LD35/LD50 2.67 1.05

CLASSIC-25 0.60 0.23

LD Series