Automatic A/C-Service Unit

2

Letzte Änderung: 24.06.2009 / Art.Nr.: 2059ENG

CONTENTS

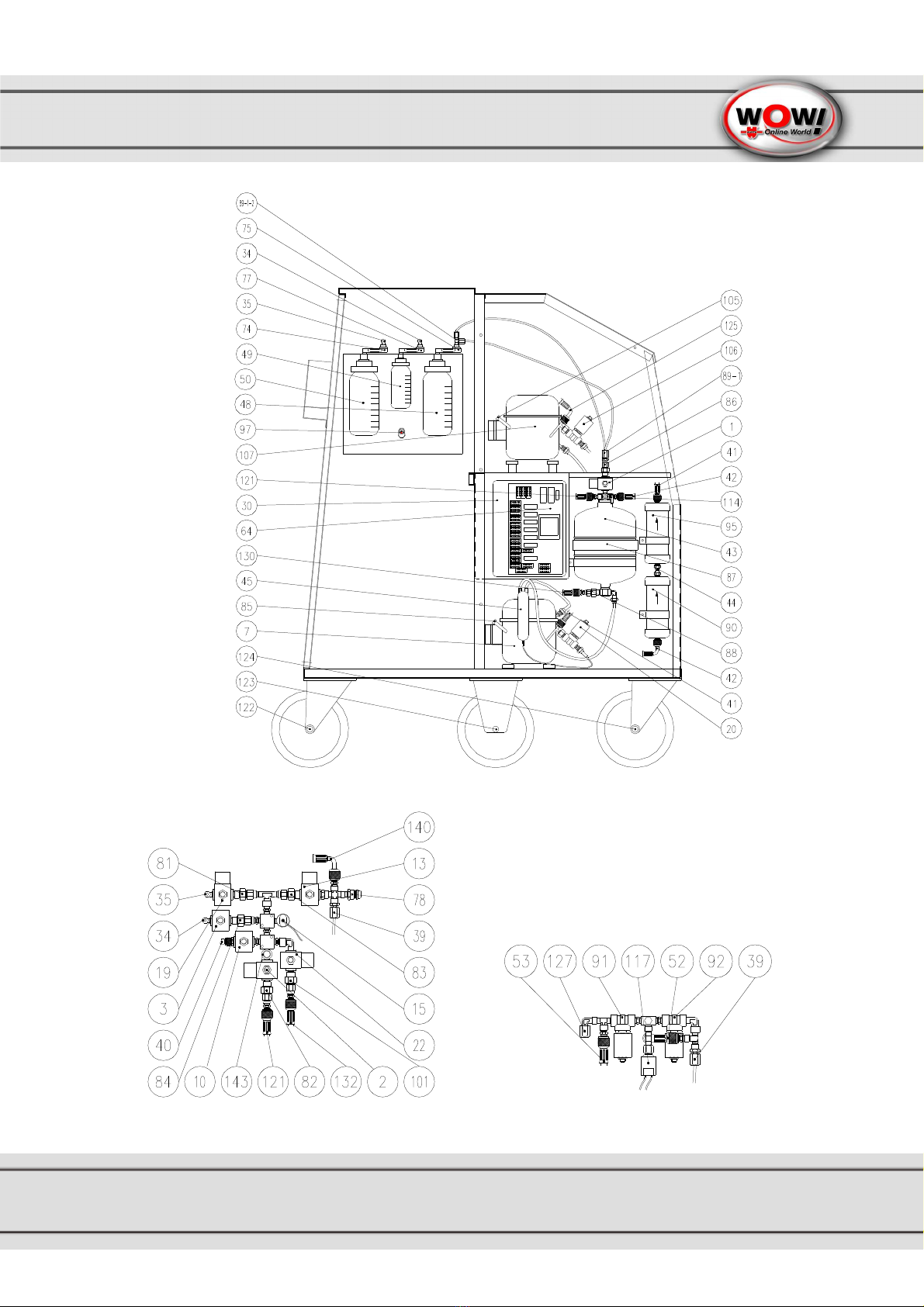

Layout drawing .......................................................................................................................5

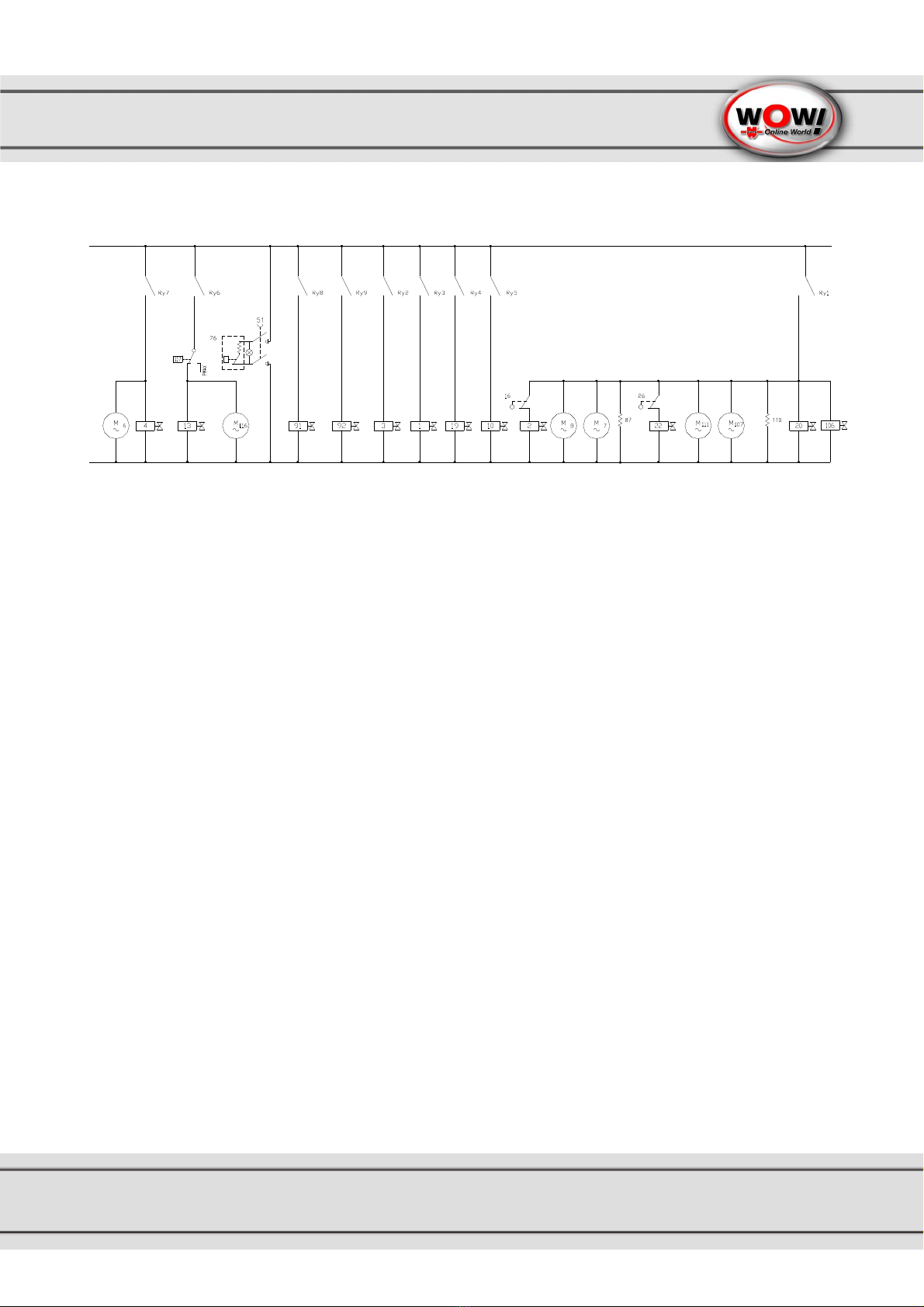

Electric scheme ......................................................................................................................9

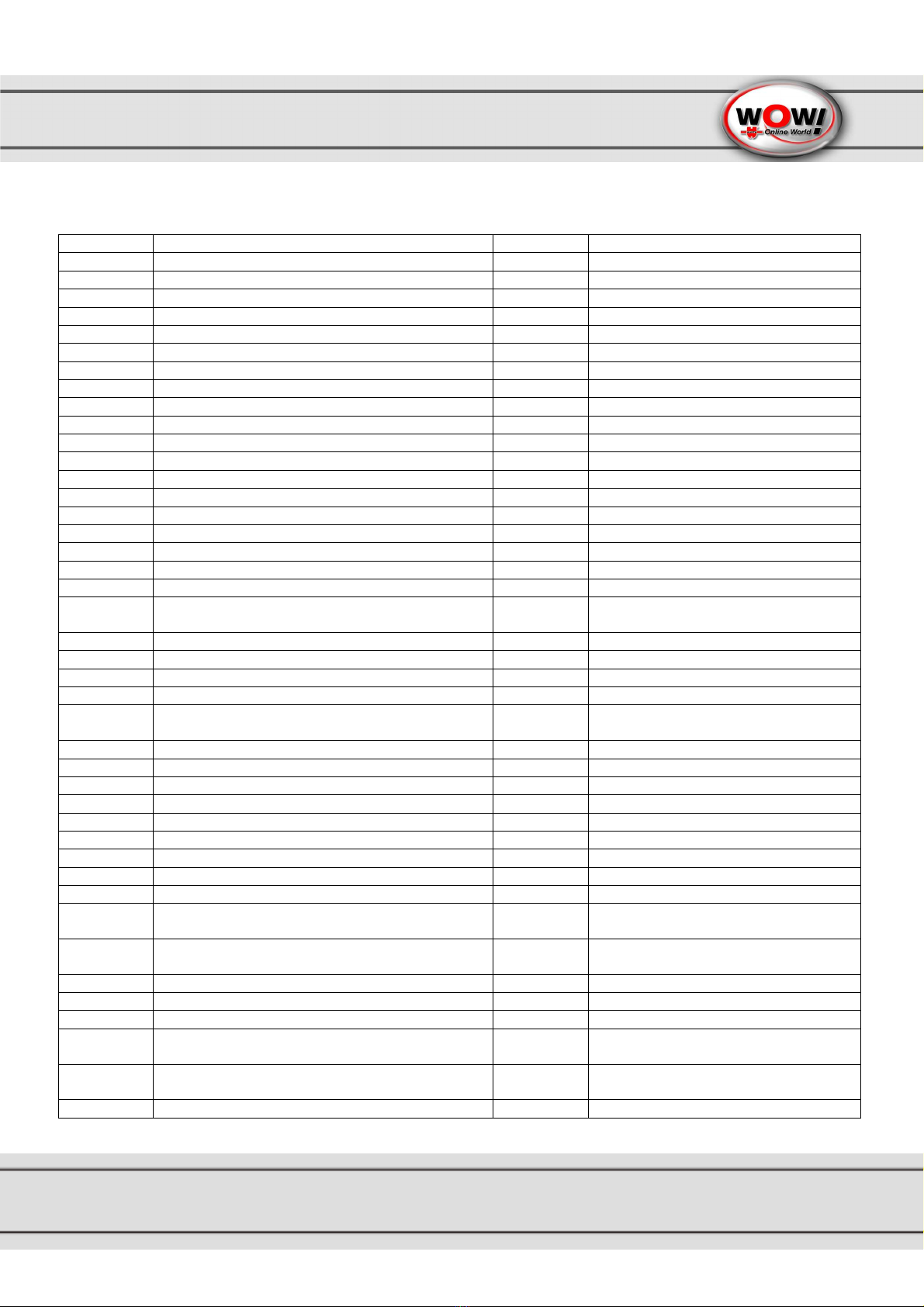

Legend...................................................................................................................................10

1. Introduction to Coolius 40000 BUS recovery unit ......................................................12

1.1

Technical specifications................................................................................................................... 12

2. Components description and standard equipment....................................................12

2.1

High vacuum pump ......................................................................................................................... 12

2.2

Refrigerant charging pump.............................................................................................................. 12

2.3

Refrigerant bottle............................................................................................................................. 12

2.4

Distiller - separator.......................................................................................................................... 13

2.5

Compressor .................................................................................................................................... 13

2.6

Filters.............................................................................................................................................. 13

2.7

Flexible hoses................................................................................................................................. 13

2.8

Quick coupler valves....................................................................................................................... 13

2.9

Printer............................................................................................................................................. 13

2.10

Temperature probe ......................................................................................................................... 13

2.11

Control module................................................................................................................................ 13

2.12

Functions programming................................................................................................................... 13

2.13

Functions that can be performed..................................................................................................... 14

3. Control panel..................................................................................................................15

3.1

Description of the control keys......................................................................................................... 15

4. Preparing the unit Coolius 4000 BUS for operation..................................................16

4.1

Checking the vacuum pump oil level................................................................................................ 16

4.2

Unlocking the scale......................................................................................................................... 16

4.3

"Zero" scale check .......................................................................................................................... 17

4.4

Filling refrigerant into the bottle ....................................................................................................... 17

4.4.1

Filling refrigerant into the internal bottle by means of recovery from the service bottle...................... 17

4.4.2

Emptying the internal bottle............................................................................................................. 19

5. Recovery ........................................................................................................................20

5.1

Preparing the vehicle for refrigerant recovery from the A/C system.................................................. 20

5.2

Refrigerant recovery for R= all......................................................................................................... 20

5.3

Refrigerant recovery for R<>00.00................................................................................................... 21

6. Draining of the oil extracted from the A/C system......................................................22

7. Evacuating and checking the A/C system for tightness ............................................22

8. Refilling oil into the A/C system...................................................................................23

8.1

Warning .......................................................................................................................................... 23

8.2

Warning .......................................................................................................................................... 23

8.3

Oil refilling procedure in the A/C system.......................................................................................... 23

8.4

Suggested oil quantities for refilling the vehicle air conditioner......................................................... 24

8.5

Warning .......................................................................................................................................... 24

8.6

UV refilling procedure in the A/C system.......................................................................................... 24

9. Charging refrigerant into the A/C system................................................................25

9.1

Warning .......................................................................................................................................... 25

9.2

A/C system refrigerant charging procedure...................................................................................... 25

10. Checking the A/C system operating pressures.......................................................25

11. FLUSHING automatic function..................................................................................26

12. FIRE&GO automatic function....................................................................................26

13. AUTO function............................................................................................................27

14. Operations before disconnecting the unit from the A/C system ...........................27