servos plug into your receiver’s aileron channel via the “Y” lead, with the servo on the other

side of the wing requiring a servo extension lead (300mm). The mini size elevator servo is

plugged into the elevator channel of your receiver.

46. Make sure the servo arms are centered in the correct position when everything is turned on

and the transmitter trims are in their neutral position. The servo arms should be pointing

directly upwards, or leaning just slightly rearwards. Unscrew the servo arms and adjust if

required. Also check for correct direction of servo travel and reverse via your transmitter if

required. Viewed from above, when your transmitter’s elevator stick is pulled back for “up”

control, your elevator servo’s arm should move forwards (towards the leading edge of the

wing), and should move backwards when “down” control is applied. When your

transmitter’s aileron stick is moved to the right for “right roll” control, the right aileron

servo’s arm should move forwards and the left aileron servo’s arm backwards, and opposite

when “left roll” control is applied.

47. Perform a “range check” for your radio equipment now. You should be able to control the

servos smoothly with no “jitters” from 10 paces away with your transmitter’s aerial fully

retracted (not extended at all).

48. Once you are satisfied that your radio equipment is functioning correctly, it’s time to start

building it into your glider. Soon, retrieval of radio equipment will require some surgery on

your glider, so it is best to make any necessary adjustments or repairs now. Also keep in

mind that you will need to have access to a means of charging your receiver’s battery pack

once it is embedded into the glider. This can be by means of a special switch with charging

socket, or as simple as having access to the battery pack’s plug (perhaps just having it plug

into an exposed socket of your receiver). If installing an exposed switch, orientate it so that

the “on” position is towards the rear of the glider so that if it brushes up against something

while flying it doesn’t switch off.

49. Coil up the excess length in the leads and insert into the recess you made next to the

receiver. Slice off an appropriate thickness from the top of the remains of this cavity’s foam

plug to form a lid and glue it in place flush with the top surface of the wing.

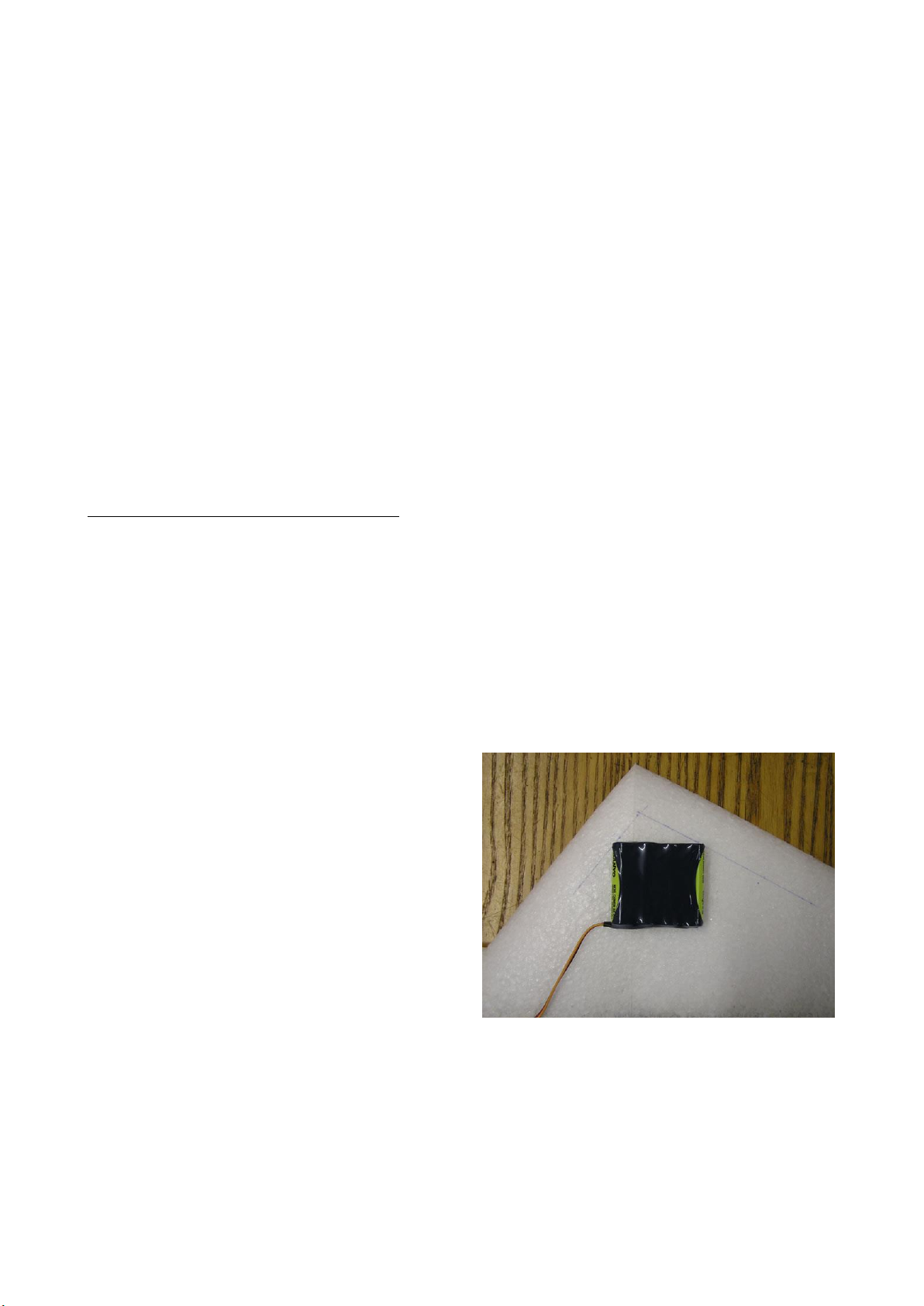

50. If you chose to embed your receiver below the wing surface, glue the top slice from your

receiver’s foam plug in place now so that it is flush with the top surface of the wing.

51. Glue the top slice of your battery pack’s foam plug so that it is flush with the top surface of

the wing.

52. Mark the mid point of the central wing panel towards its leading edge.

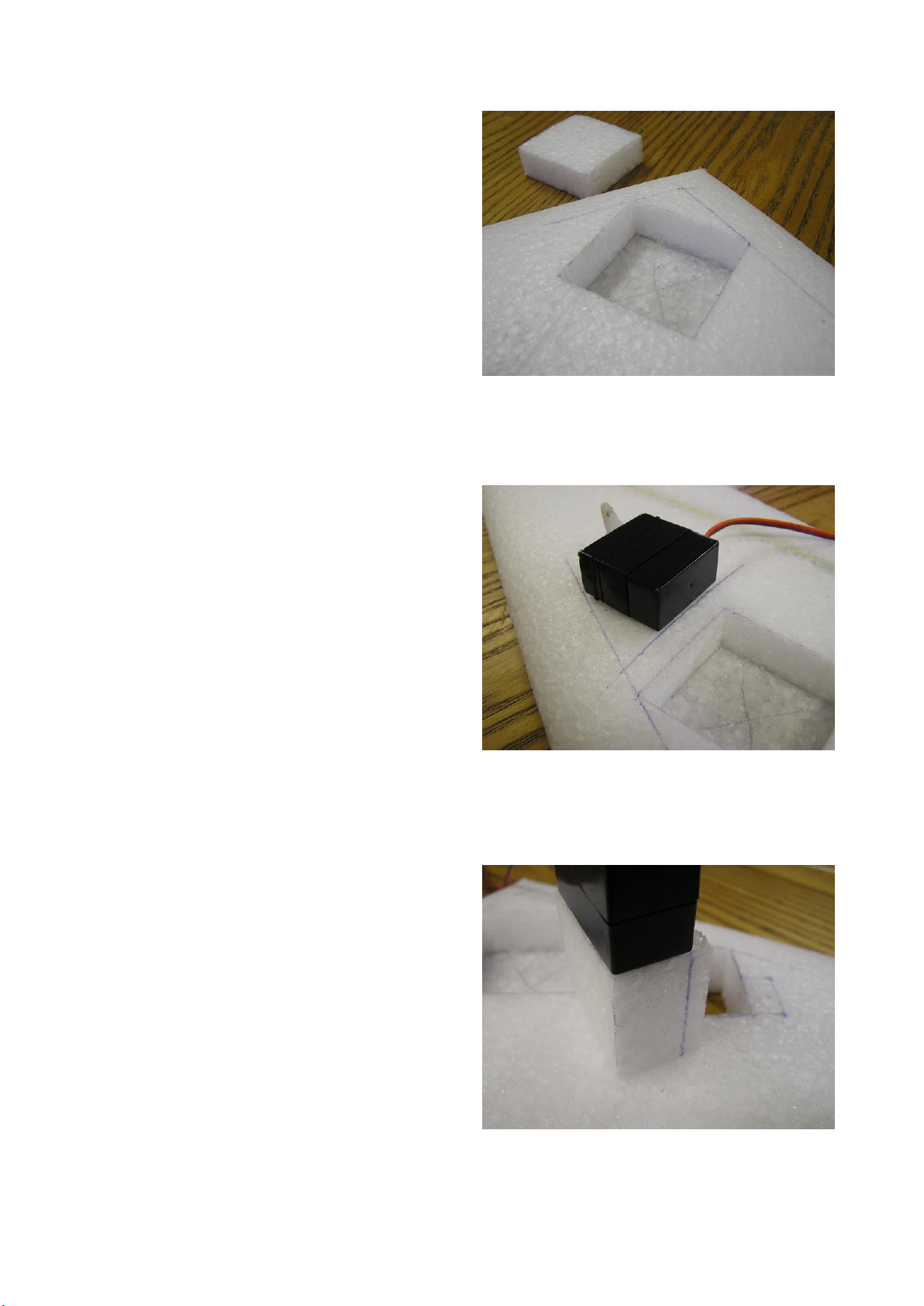

53. Cut 3 pieces of lead from a flat sheet of 1mm thick lead flashing, each measuring the same

size as your battery pack’s recess (approx. 50mm x 55mm).

54. Insert enough lead into the recess on the glider’s other nose (the one that doesn’t contain the

battery pack) so that the glider balances exactly at the mid point you marked on the central

wing panel. It will likely require around 2 ½ pieces of the lead flashing (approx. 100 to 110

grams). If the final piece is not a full piece, place it as far forward in the recess as possible

and tape it with some filament tape to the piece which is underneath to prevent it from

shifting.

55. Measure the distance at each corner from the top of the lead to the top surface of the wing.

Cut a slice of appropriate thickness from the top of the remains of this cavity’s foam plug to

form a lid. Glue this in place so that it is flush with the wing’s top surface.

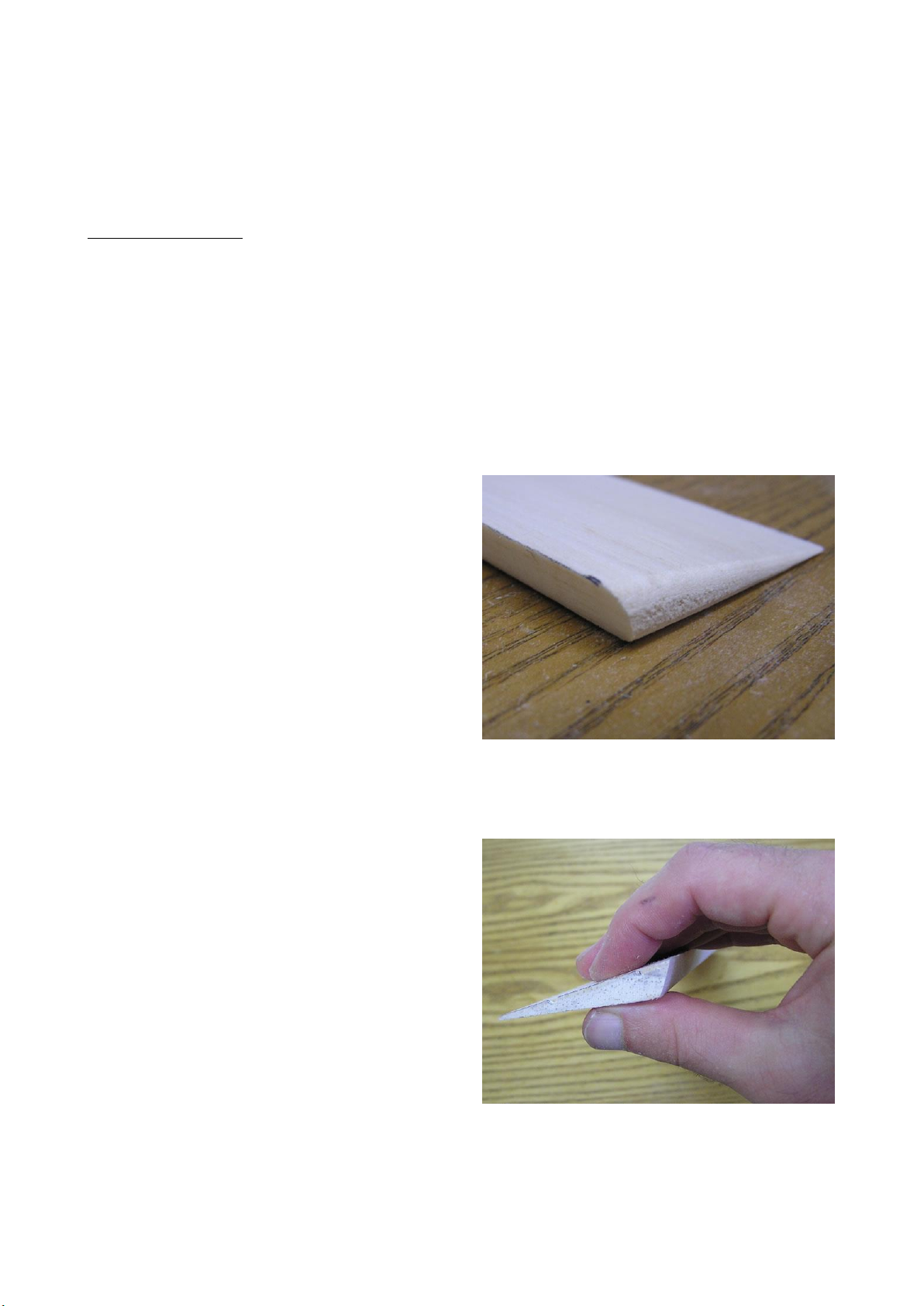

56. Cut and/or sand off any excess glue from around the foam plugs so that they’re all flush

with the surface of the wing.