5WPL/GG2O&M/0704/v5

3. CUSTOMERS OPERATION MANUAL FOR GREASE GUZZLER®

The operation of the WPL Grease Guzzler®is fully automatic and only requires minimal user maintenance

once your supplier has commissioned the unit (Item 5, Installation Manual). Your maintenance contract is

with your supplier at an agreed interval.

The Grease Guzzler® regulates the dosing of a solution, known as biouid, containing active bacteria and

enzymes into your drain lines at a set time each day, normally when the kitchen has closed for the night or

at a pre-determined quiet period. This active solution will assist in keeping the drain lines free from build

up of fats, grease and oils. The complete cycle is pre-set for a period normally between two and ve hours

during which time the solution is held at 38-400C to activate the bacteria.

You can monitor the automatic operation using a series of indicator lights provided on the front panel. All

lights have a description adjacent, a full explanation of the purpose follows:-

Bio-Fluid Low/Call Engineer indicates when biouid supply is low, contact service engineer.

Power On Indicates the electrical supply is live

Heater On Indicates the activity of the heater

4. SEQUENCE OF OPERATION: -

At all times the POWER ON should be illuminated. During the operating cycle the following sequence

can be observed:

‘On Lamp’ on – heating on lamp will go off when the water is at the required temperature and will then

periodically come on to maintain the desired temperature.

4.1. Operating Instructions

Important Safety Notice

Only a qualied technician may open the Grease Guzzler®. Before opening the door, isolate the

machine from the mains electricity supply. Ensure that the Grease Guzzler®has its door shut and

locked, with its operating key removed, when unattended to prevent access by unauthorised personnel.

4.2. Setting up of daily dosage

Please refer to Appendix I for details of how to set up multi-dosing. The unit is pre-set to one dose per

day.

Ensure that there is power supplied to the Grease Guzzler®(Power on indicator illuminated)

Ensure that there is an adequate water supply to the Grease Guzzler® so that the tank lls in a

MINIMUM of one (1) minute.

4.3. For test operation of the Grease Guzzler®

Press the red push-button for a count of ten seconds and the test run will automatically come into

operation. All lights will come on, bacteria feed pump will operate and the heater pad will come on.

This can be checked through the specically designed aperture.

4.4. Capacities and consumption rates (Approximate)

Bio-uid bag capacity = Six months supply at one dose per day

Mixing tank capacity = 2.5 litres (Liquid capacity/dispense rate/cycle at 35 to 40 C)

Dosing rate = Up to 4 cycles per day, with a minimum of 6 hours between dosing.

Bio-uid consumption = 25 ml per cycle

4.5. Dimensions: Enclosure (width x height x depth) = 530 x 560 x 200 mm

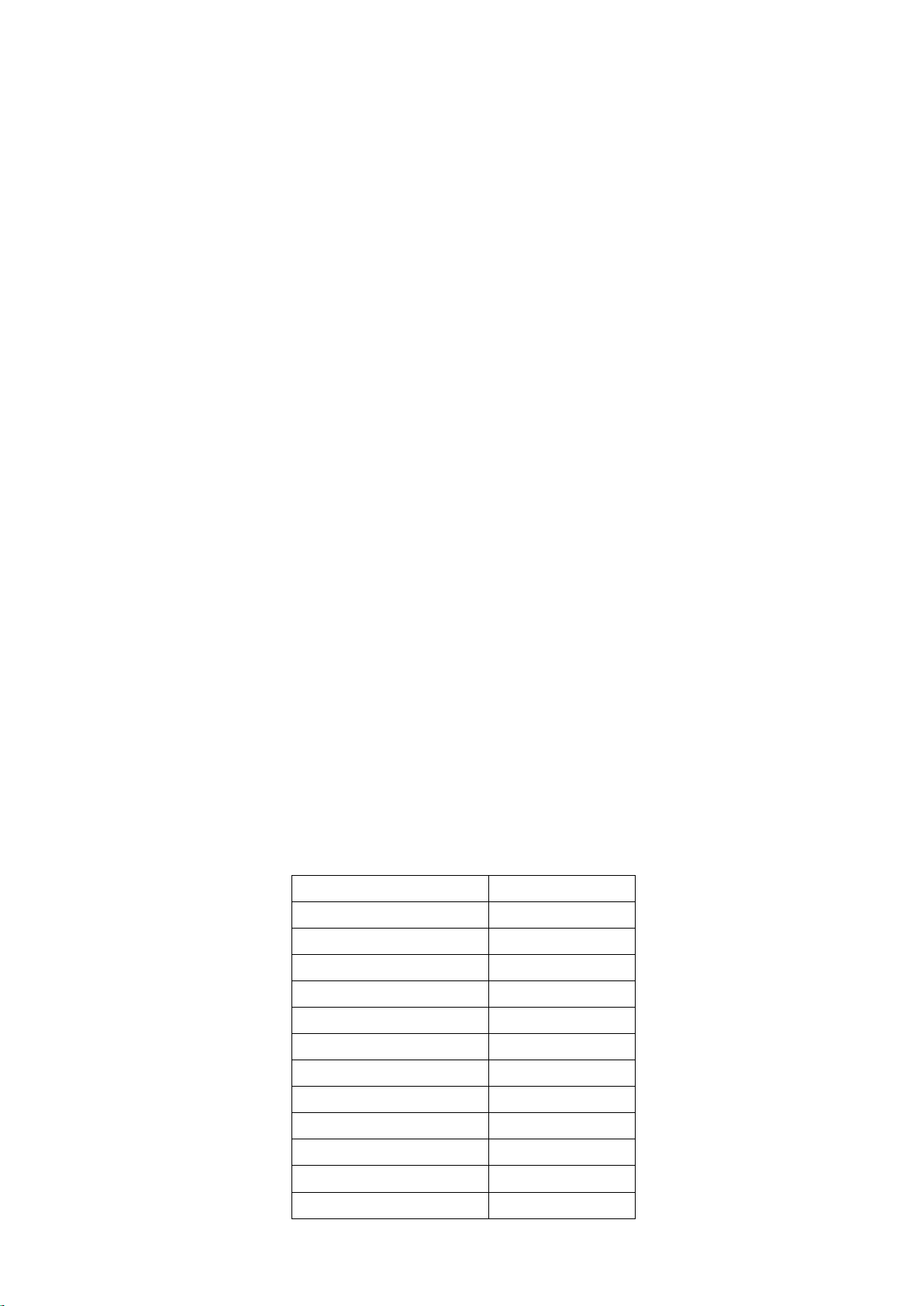

Check Method Interval

Bio-Fluid level Bio-Fluid warning light Weekly

Function

Check

Press/ick the test button/switch for 10 seconds and observe the test

cycle. Six monthly

Cleanliness Wash down the outside of the machine to remove any spillage and dirt

build up. Weekly

De-scaling and

Cleaning

Add a de-scaling solution to boiling water and pour into the incubation tank.

Leave the solution in the tank for ve minutes and run the test cycle once.

Once de-scaling is complete, continue to use as normal.

Annual