WIM-WG-001_E PAGE 6 of 21

4.0 INSTALLATION

NOTE: For units with model number WTD-13-130 or WTD-13-133, the factory flywheel offset is set to

standard SAE #3. For alternate offset settings see Section 9.1.

4.1 Clean the friction surface of the flywheel and pressure plate with an appropriate cleaning solvent to

remove any oil and grease.

4.2 Use an alignment tool to center the clutch plate on the flywheel, if necessary. The pressure plate side

of the clutch plate should face out.

NOTE: For the PTO’s with model number WTD-11-143 or WTD-11-144, see Section 14 for complete

alignment tool details.

4.3 Place the pressure plate and clutch plate in position on the flywheel and assemble using grade 8

bolts. Make sure alignment tool is in place, and then tighten the bolts evenly in an alternating pattern.

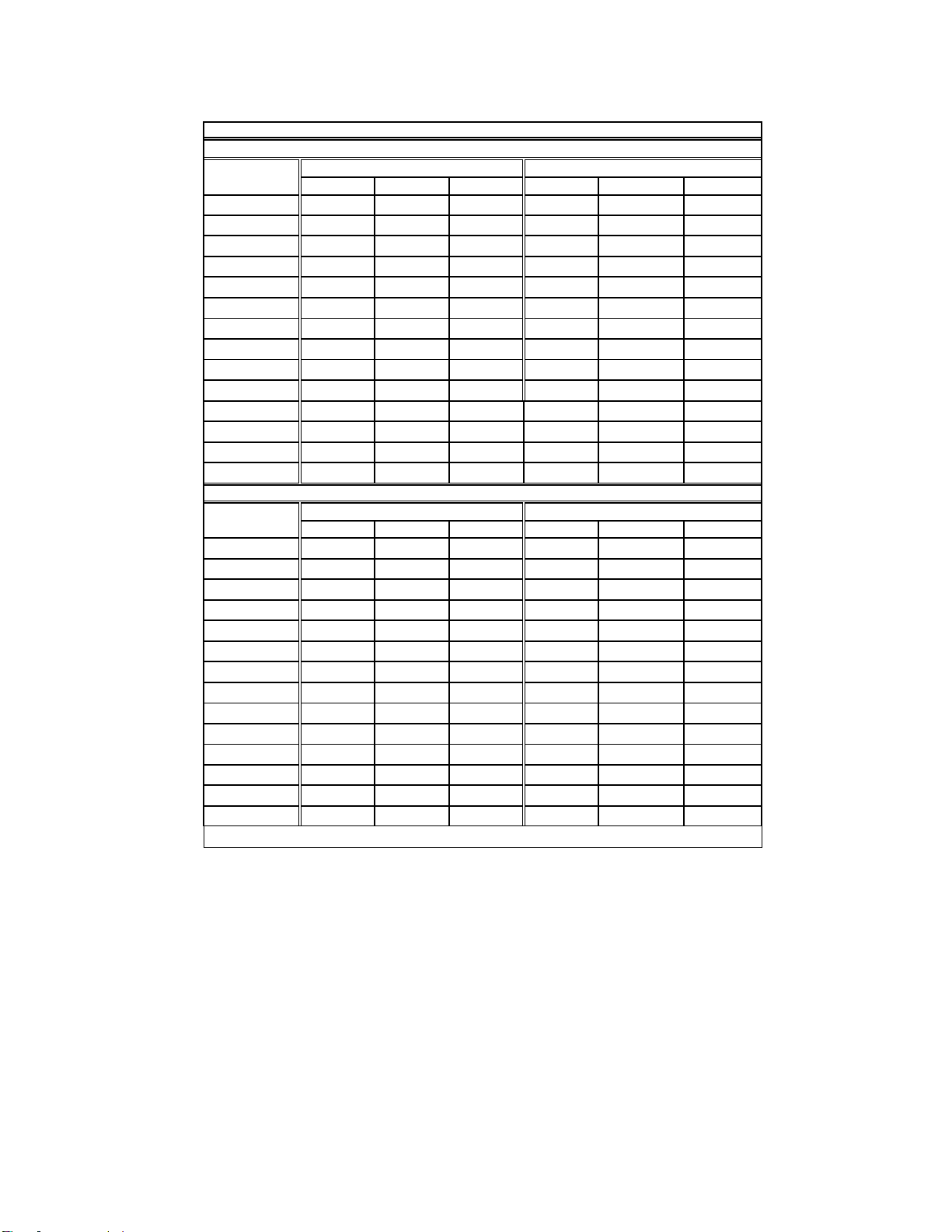

Torque bolts to the specifications in Chart 1 on page 10 or to the engine manufacturer’s torque. Use

the engine manufacturer's torque recommendation if different from that in Chart 1. The alignment tool

can now be removed.

CAUTION:

The PTO is heavy. Use approved lifting equipment and procedures to prevent accident or injury.

4.4 Insert guide pins into the engine flange face 180apart in order to properly align the PTO bellhousing

and shaft with the engine.

4.5 Remove inspection hand hole cover from the PTO bellhousing. Align the PTO bellhousing and

shaft parallel with the engine crankshaft.

4.6 Advance the PTO bellhousing onto the guide pins carefully. Continue until it is against the engine

flywheel housing. Remove the guide pins and install grade 5 or better hex head cap screws to attach

the bellhousing to the engine. Torque bolts to the specifications in Chart 1 on page 10 or to the engine

manufacturer’s torque. Use the engine manufacturer's torque recommendation if different from that in

Chart 1.

4.7 Place the hand lever on the desired side of the operating shaft. Secure with the appropriate hex head

cap screw. The hand lever should be at a 5to 10angle from vertical toward the engine when the

clutch is completely disengaged, see appropriate drawing at the back of this manual, page 11.

4.8 For initial adjustment of clutch: See adjustment instruction in Section 7.0.

4.9 Replace hand hole cover and attach with screws prior to use.

WARNING:

The WPT mechanical PTO is capable of side load and inline power transmission applications. Special care should be

exercised when installing the PTO in an inline application. Due to engine movement and other factors that may cause

misalignment, WPT recommends that a flexible coupling or drive shaft be used to join the PTO and driven shaft. If a

coupling is used, ensure that it has sufficient horsepower capacity and that shafts are in line within the limits specified

by the coupling manufacturer. If you are unsure about the procedure to align these shafts, consult the coupling

manufacturer or WPT Power.

5.0 LUBRICATION

5.1 The throw-out bearing and main bearings are sealed for life and require no lubrication except WTD-

11-143 & WTD-11-144 units pack using EP-2 Lithium based grease or equal every 300 hours.

However, they should be inspected every two years for wear or damage.

5.2 Apply one shot of grease every 100 hours of use to all fittings on the operating shaft. Use a good

quality lithium-based grease (300F minimum drop point, No. 2 NGLI).