Page 4 of 18 WIM-CG-001_F

3.3 Installing the sheave

3.3.1 If the key(57) is not in the shaft, install it now. Be sure it seats in the bottom of the slot.

3.3.2 Measure the distance from the top of the key to the opposite side of the shaft.

3.3.3 Compare this measurement to the mating dimension in the sheave or bushing and adjust the

key height if necessary.

3.3.4 Slide the sheave onto the shaft and lock in the approximate center determined in 3.1.1 above.

3.4 Replacing the outboard bearing

If the outboard bearing(45) is not assembled as a unit with the bearing carrier(41), seal housings

(32 & 33), and seals(36), go to section 9.3.24

3.4.1 Slide the seal spacer(43) onto the shaft until it seats against the shoulder.

3.4.2 Install the outboard bearing(45) with its carrier(41), seal housings(32 & 33), and seals(36) onto

the shaft. Use a light coating of grease on the seal ring and be careful to not damage the seal.

3.4.3 Slide the remaining seal spacer(43) onto the shaft. Use a light coating of grease on the seal ring

and be careful to not damage the seal.

3.4.4 Install the bearing lockwasher(48) and locknut(51) tightening the nut ¼ turn past makeup or

hand tight. Lock the nut with one of the tabs of the lockwasher.

3.4.5 If the rotary coupling(50) was removed, install it in its counterbore and lock in place with ring(49)

and 4 socket head bolts(26).

3.5 Replacing the sheave housing

3.5.1 Refer to 9.4.1

4.0 INSTALLATION

4.1 Flywheel and flywheel housing alignment checks

It is strongly recommended that these dial indicator checks be made prior to installation of the

PTO, especially on new engines or when a previous PTO failure might indicate an alignment

problem.

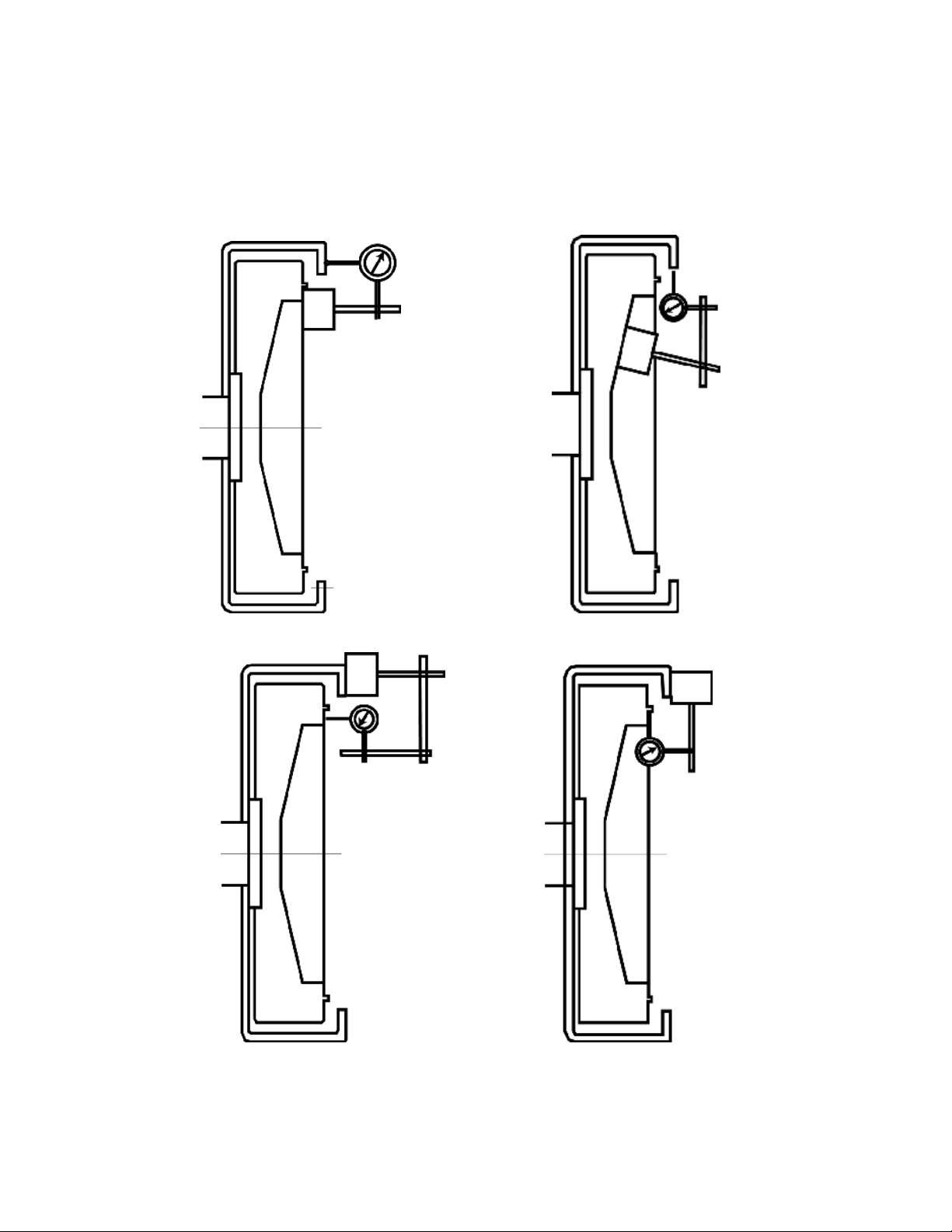

4.1.1 Flywheel to housing face runout check. (see Figure 3)

Mount the indicator base on the face of the flywheel and position the dial indicator tip

perpendicular to the flywheel housing mounting face. Rotate the flywheel 360 degrees while

holding pressure against the crankshaft thrust bearing.

SAE #1 Housing: 0.012 inches (0.305 mm)

SAE #1/2 Housing: 0.014 inches (0.356 mm)

SAE #0 Housing: 0.016 inches (0.406 mm)

SAE #00 Housing: 0.019 inches (0.483 mm)

4.1.2 Check flywheel housing bore runout. (see Figure 4)

Mount the indicator base on the face of the flywheel and position the dial indicator tip so its

movement is perpendicular to the pilot bore of the flywheel housing.

Rotate the flywheel through 360 degrees. The total indicator reading should not exceed:

SAE #1 Housing: 0.012 inches (0.305 mm)

SAE #1/2 Housing: 0.014 inches (0.356 mm)

SAE #0 Housing: 0.016 inches (0.406 mm)

SAE #00 Housing: 0.019 inches (0.438 mm)

4.1.3 Check flywheel face runout. (see Figure 5)

Mount the indicator base on the flywheel housing and position the dial indicator tip so that its

movement is perpendicular to the face of the flywheel. Position the indicator tip near the drive

ring mounting bolt circle diameter. Rotate the flywheel 360 degrees while holding pressure

against the crankshaft thrust bearing.