For Customer Care call: Toll Free 800-562-5625 or info@hamptonproducts.com

DOOR CLOSER

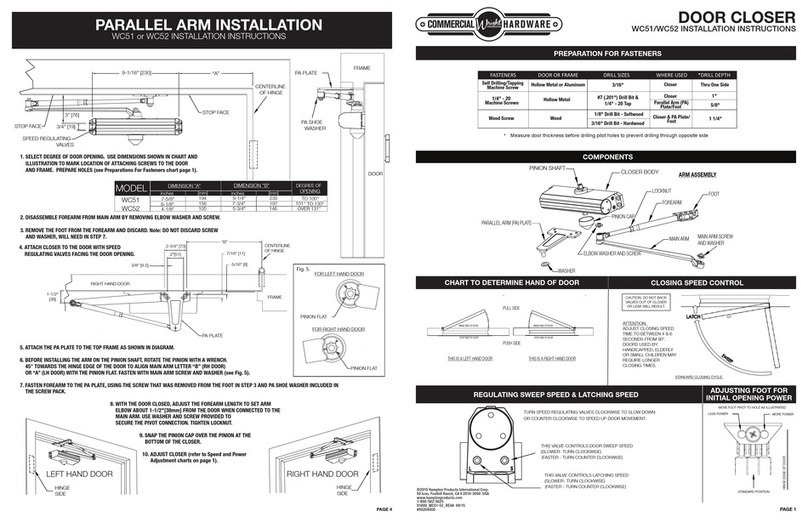

WC13/WC14 INSTALLATION INSTRUCTIONS

INWARD OPENING DOORS

OUTWARD OPENING DOORS

Cut out the right or left hand template marked “INWARD OPENING”. Tape the

template to the upper edge of the door on the hinge side, following template

instructions for desired degree opening.

The templates are in two parts. Cut out the right or left hand templates marked “OUTWARD

OPENING”. Tape the closer body and forearm shoe templates following the template instructions

for desired degree opening.

3B. MARKING HOLE LOCATION.

Use a hammer and punch to mark the center of each

screw

hole then remove the template.

3C. PREPARING SCREW START HOLES

NOTE: Numbers in parentheses ( ) indicate the item

number shown in Parts and Assembly Diagram on the

front of this sheet.

a. Wood Door

Soft Wood – use a 1/8” drill bit and drill four holes for the

closer body (1) and two holes for the forearm and shoe

assembly (3) 1-1/4” deep.

Hard Wood – use a 5/32” drill bit and drill four holes for the

closer body (1) and two holes for the forearm and shoe

assembly (3) 1-1/4” deep.

b. Aluminum or Steel Door

Use a drill with a 5/32" bit and drill four holes for the body

(1) and two holes for the forearm shoe (3) approximately

3/4" deep.

3D. ATTACHING MAIN

ARM TO BODY

NOTE: Speed adjustment

valve on closer body

must be positioned

towards the door hinge.

Place main arm onto the

BOTTOM spindle of the

closer body for an outward

opening door and attach

with hex screw, lock

washer and flat washer.

3E. ATTACHING BODY

Position closer body with

main arm attached over the

drilled holes on the jamb.

The spindle with main arm

attached must be on the

bottom. Fasten closer to

door using screws for either

wood or aluminum door

jambs.

3F. ATTACHING

FOREARM AND SHOE

ASSEMBLY

Position the forearm shoe

over holes on the door and

fasten using screws for

either wood or aluminum

doors.

3D. ATTACHING MAIN

ARM TO BODY

NOTE: Speed adjustment

valve on closer body

must be positioned

towards the door hinge.

Place main arm onto the

TOP spindle of the closer

body for an inward

opening door and attach

with hex screw, lock

washer and flat washer.

3E. ATTACHING BODY

Position closer body with

main arm attached over

the drilled holes on the

door. The spindle with

main arm attached must

be on the top. Fasten

closer to door using

screws for either wood or

aluminum doors.

3F. ATTACHING

FOREARM AND SHOE

ASSEMBLY

Position the forearm

shoe over holes on the

top door jamb and

fasten using screws for

either wood or aluminum

door jambs.

TAPE

HINGE

OPPOSITE

Right Hand Door

HINGE

TAPE TAPE

HINGE

Left Hand Door

Right Hand Door

HINGE

OPPOSITE

TAPE

Left Hand Door

ATTENTION

:

ADJUST CLOSING SPEED

TIME TO BETWEN 4 & 6

SECONDS FROM 90°.

DOORS USED BY:

HANDICAPPED, ELDERLY

OR SMALL CHILDREN MAY

REQURE LONGER

CLOSING TIMES.

STANDARD

CLOSING

CYCLE

10°

CLOSING SPEED CONTROL

3G. CONNECTING MAIN ARM TO FOREARM

Adjust length of forearm to position the forearm at a right angle to

frame, when connected to main arm at the elbow. Use washer and

screw (4) provided to secure the pivot connection. Tighten forearm

locknut.

Important: When door is fully closed and the forearm is at a 90

degree angle to the door, this position creates pressure, which

forces the door closed.

4. SPEED ADJUSTMENT

Closer speed is factory set. If a different speed is desired, both

sweep and latch speed can be adjusted by a single screw

adjustment.

4A. SWEEP SPEED ADJUSTMENT

Turn speed adjustment screw clockwise (1 turn) for a slower speed

and counter clockwise (1 turn) for a faster speed. Do not exceed two

turns in either direction.

4B. LATCHING SPEED ADJUSTMENT

For fastest latching speed, the slot in the adjustment screw is parallel

to the door. For a slower latching speed, the slot in the adjustment

screw is perpendicular to the door.

5. ATTACH COVER

Slide cover (8) onto body (1).

ADJUSTING LENGTH OF FOREARM

(template #1) (template #2)

(template #3) (template #4)

CAUTION: DO NOT BACK

VALVES OUT OF CLOSER

OR LEAK WILL RESULT.

3G

PRELOAD

MAIN ARM

90

LATCH SPEED

ADJUSTMENT

SWEEP SPEED

ADJUSTMENT

ADJUSTING

SCREW

6. INITIAL OPENING POWER ADJUSTMENT

Adjusting foot for opening power (see illustration on right)

4A

4B

MOVE FOOT PIVOT TO HOLE AS ILLUSTRATED

LESS POWER MORE POWER

STANDARD POSITION

HINGE EDGE OF DOOR

ADJUSTING FOOT FOR INITIAL OPENING POWER

ADJUSTING SCREW

ADJUSTING SCREW

BODY

BODY

MAIN ARM

MAIN ARM

MAIN ARM

SCREW

HINGE

MAIN ARM

SCREW

WOOD OR

SELF-TAPPING

SCREWS

WOOD OR

SELF-TAPPING

SCREWS

WOOD OR

SELF-TAPPING

SCREWS

FOREARM

FOREARM

CONNECTING

SCREW

WOOD OR

SELF-TAPPING

SCREWS

FOREARM

CONNECTING

SCREW

FOREARM

HINGE

3D 3D

3E 3E

3F 3F