PAGE 1

PARALLEL ARM INSTALLATION

WC51 or WC52 INSTALLATION INSTRUCTIONS

PAGE 4

©2015 Hampton Products International Corp.

50 Icon, Foothill Ranch, CA 9 2610-3000 USA

www.hamptonproducts.com

1-800-562-5625

91000_WC51-52_REVA 09/15

#95264000

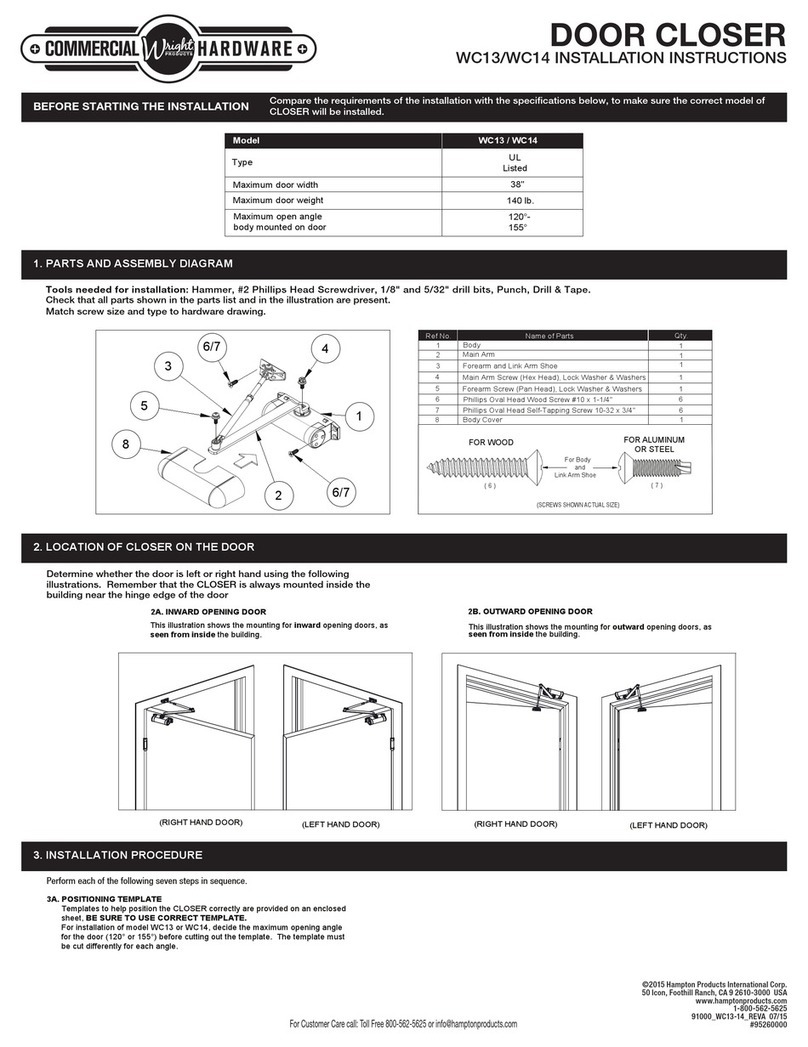

DOOR CLOSER

WC51/WC52 INSTALLATION INSTRUCTIONS

PULL SIDE

PUSH SIDE

HINGE SIDE OF DOOR

STOP SIDE OF DOOR

THIS IS A RIGHT HAND DOOR

STOP SIDE OF DOOR

HINGE SIDE OF DOOR

THIS IS A LEFT HAND DOOR

PREPARATION FOR FASTENERS

COMPONENTS

CHART TO DETERMINE HAND OF DOOR CLOSING SPEED CONTROL

REGULATING SWEEP SPEED & LATCHING SPEED

THIS VALVE CONTROLS LATCHING SPEED

(SLOWER- TURN CLOCKWISE)

(FASTER - TURN COUNTER CLOCKWISE)

THIS VALVE CONTROLS DOOR SWEEP SPEED

(SLOWER- TURN CLOCKWISE)

(FASTER - TURN COUNTER CLOCKWISE)

TURN SPEED REGULATING VALVES CLOCKWISE TO SLOW DOWN

OR COUNTER CLOCKWISE TO SPEED UP DOOR MOVEMENT.

MOVE FOOT PIVOT TO HOLE AS ILLUSTRATED

LESS POWER MORE POWER

STANDARD POSITION

HINGE EDGE OF DOOR

STANDARD CLOSING CYCLE

10°

CAUTION: DO NOT BACK

VALVES OUT OF CLOSER

OR LEAK WILL RESULT.

ATTENTION:

ADJUST CLOSING SPEED

TIME TO BETWEEN 4 & 6

SECONDS FROM 90°.

DOORS USED BY:

HANDICAPPED, ELDERLY

OR SMALL CHILDREN MAY

REQUIRE LONGER

CLOSING TIMES.

ADJUSTING FOOT FOR

INITIAL OPENING POWER

PINION CAP

PARALLEL ARM (PA) PLATE

WASHER

FOREARM

MAIN ARM

ELBOW WASHER AND SCREW

FOOT

LOCKNUT

ARM ASSEMBLY

CLOSER BODY

PINION SHAFT

MAIN ARM SCREW

AND WASHER

FASTENERS DOOR OR FRAME DRILL SIZES WHERE USED *DRILL DEPTH

Self Drilling/Tapping

Machine Screw Hollow Metal or Aluminum 3/16" Closer Thru One Side

1/4" - 20

Machine Screws Hollow Metal #7 (.201") Drill Bit &

1/4" - 20 Tap

Closer 1"

Parallel Arm (PA)

Plate/Foot 5/8"

Wood Screw Wood 1/8" Drill Bit - Softwood Closer & PA Plate/

Foot 1 1/4"

3/16" Drill Bit - Hardwood

* Measure door thickness before drilling pilot holes to prevent drilling through opposite side

1. SELECT DEGREE OF DOOR OPENING. USE DIMENSIONS SHOWN IN CHART AND

ILLUSTRATION TO MARK LOCATION OF ATTACHING SCREWS TO THE DOOR

AND FRAME. PREPARE HOLES (see Preparations For Fasteners chart page 1).

MODEL DIMENSION "A" DEGREE OF

OPENING

inches [mm]

WC51

WC52

7-5/8" 194 TO 100°

6-1/8" 156 101

°

TO 130°

4-1/8" 105 OVER 131°

inches [mm]

235

7-3/4"

9-1/4"

5-3/4"

197

146

DIMENSION "B"

9-1/16" [230] “A”

3/4" [19]

CENTERLINE

OF HINGE

FRAME

DOOR

PA SHOE

WASHER

PA PLATE

SPEED REGULATING

VALVES

STOP FACE

STOP FACE

3” [76]

LEFT HAND DOOR RIGHT HAND DOOR

HINGE

SIDE

HINGE

SIDE

4. ATTACH CLOSER TO THE DOOR WITH SPEED

REGULATING VALVES FACING THE DOOR OPENING.

5. ATTACH THE PA PLATE TO THE TOP FRAME AS SHOWN IN DIAGRAM.

6. BEFORE INSTALLING THE ARM ON THE PINION SHAFT, ROTATE THE PINION WITH A WRENCH.

45° TOWARDS THE HINGE EDGE OF THE DOOR TO ALIGN MAIN ARM LETTER “B” (RH DOOR)

OR “A” (LH DOOR) WITH THE PINION FLAT. FASTEN WITH MAIN ARM SCREW AND WASHER (see Fig. 5).

7. FASTEN FOREARM TO THE PA PLATE, USING THE SCREW THAT WAS REMOVED FROM THE FOOT IN STEP 3 AND PA SHOE WASHER INCLUDED IN

THE SCREW PACK.

8. WITH THE DOOR CLOSED, ADJUST THE FOREARM LENGTH TO SET ARM

ELBOW ABOUT 1-1/2"[38mm] FROM THE DOOR WHEN CONNECTED TO THE

MAIN ARM. USE WASHER AND SCREW PROVIDED TO

SECURE THE PIVOT CONNECTION. TIGHTEN LOCKNUT.

9. SNAP THE PINION CAP OVER THE PINION AT THE

BOTTOM OF THE CLOSER.

10. ADJUST CLOSER (refer to Speed and Power

Adjustment charts on page 1).

PINION FLAT

FOR LEFT HAND DOOR

PINION FLAT

FOR RIGHT HAND DOOR

Fig. 5.

1-1/2"

[38]

2"[51]

2-3/4" [70]

3/8" [9.5]

RIGHT HAND DOOR

PA PLATE

7/16" [11]

5/16" [8]

FRAME

“B” CENTERLINE

OF HINGE

2. DISASSEMBLE FOREARM FROM MAIN ARM BY REMOVING ELBOW WASHER AND SCREW.

3. REMOVE THE FOOT FROM THE FOREARM AND DISCARD. Note: DO NOT DISCARD SCREW

AND WASHER, WILL NEED IN STEP 7.