2

--

Attention

For your safety, please pay attention to the instructions above!

A. Warning:

1. Never use the Spray Gun to spray people or animals.

2. Be careful of the high temperature of the engine during operation.

3. Do not smoke, light a fire or cover the machine when using it.

4. Do not use the machine in an enclosed space to avoid suffocation

or carbon monoxide poisoning.

5. To avoid injury from spraying water and noise, wear goggles and

earplugs during operation.

B. Precautions before use:

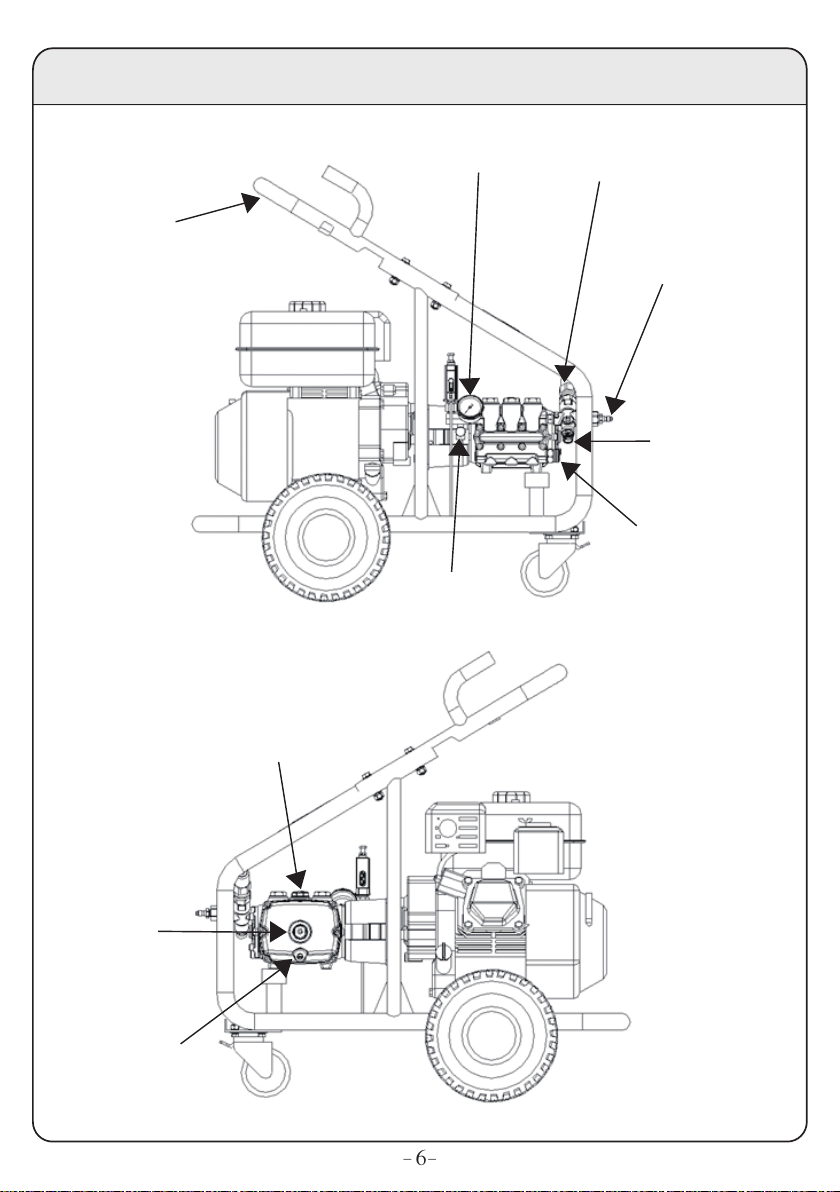

1. Make sure the oil in the pump and engine is sufficient and in good

condition. Make sure the fuel used for the engine is correct.

2. Make sure that the engine start switch and carburetor switch are on.

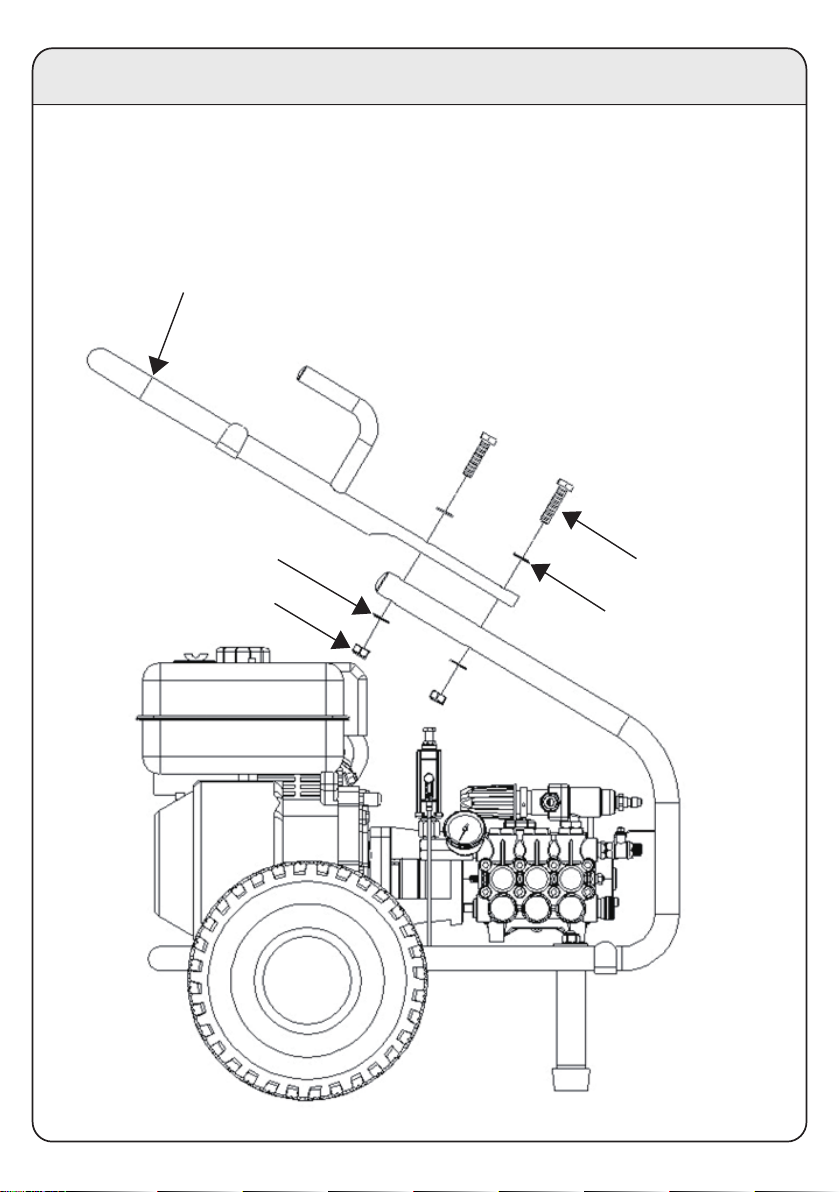

3. Check each fastener to ensure that the pump and engine are

securely mounted to the frame.

4. The water temperature should not exceed 60℃.

※Please read the engine instruction manual before use.