Operation Instructions

A. Operating Instructions

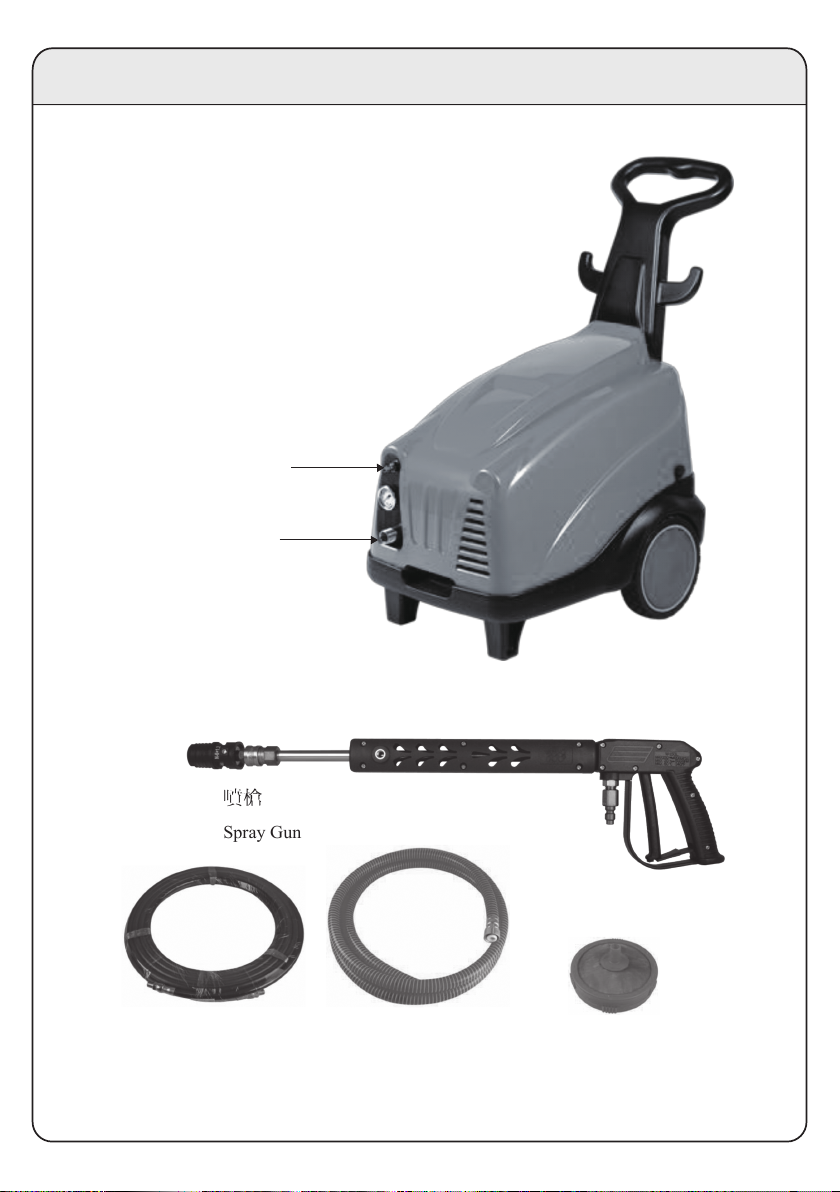

1. Make sure the oil in the pump is sufficient and in good condition before use. Connect the

Suction Hose to the Water Inlet of the cleaner and secure the hose; connect the High

Pressure Hose to the Water Outlet.

2. Put the Suction Hose (with Filter) into the water tank or connect the Suction Hose to a faucet.

When using the faucet, make sure that faucet flow rate is higher than 13 liters per minute and

that the water flows smoothly.When using a water tank, suspend the Suction Filter around 20cm

above the bottom of the water tank to avoid suctioning residue which might reduce the product's

life.

3. Make sure the power supply voltage and frequency matches the cleaner requirement.

4. Using the High Pressure Hose to connect the Spray Gun to the cleaner, remove the Spray Gun

nozzle and squeeze the trigger of the Spray Gun to release air from the cleaner when first

starting. After the outlet is normal, put the Spray Gun nozzle back and start operating.

5. When finished using the cleaner, turn off the Power Switch and squeeze the Spray Gun trigger

again to release the pressure stored in the High Pressure Hose.

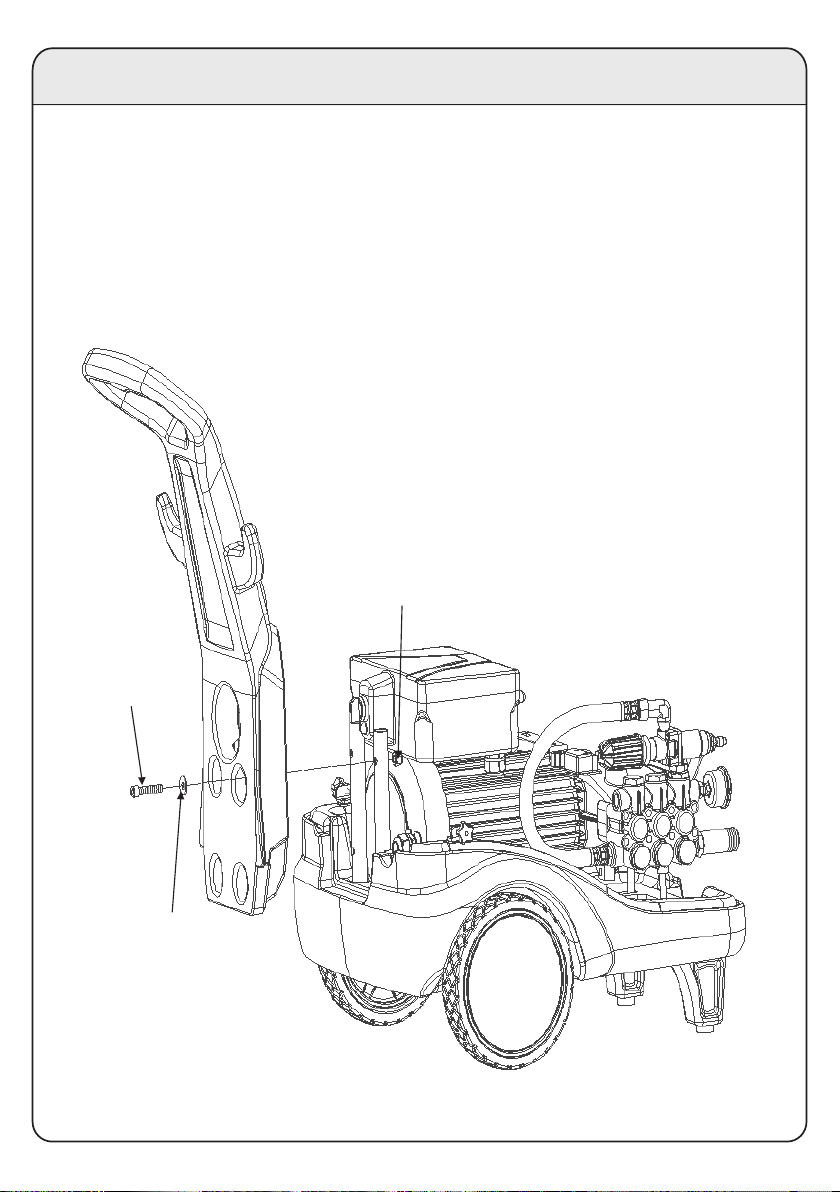

B. Oil Change

1. Replace the oil in the pump after the first 100 hours of use. After this, the oil should be changed

after every 300 hours of use.

2. Unscrew the Oil Drainage Screw and drain the oil from the pump.

3. Tighten the Oil Drainage Screw before refilling with clean motor oil SAE #30~#40 up to the

level of 2/3 of the Oil Window

※Attention: When replacing the oil, please turn off the power and make sure that the

oil temperature has cooled before replacing.

C. Reminders

1. Always use clean water with the cleaner.

2. If using an extension cord, the length of it should not exceed 10 meters. If its length is longer

than 10 meters, please make sure it is thicker than 5.5mm.

3. Be sure to change the oil according to the Oil Change section or the pump might be damaged.

4. The cleaner’s location should be no more than 1.3 meters higher than the Suction Filter.

5. The water temperature should not exceed 60℃.

6. If using water containing chemicals, detergents or other substances, please run the cleaner with

clean water for one minute after use to prolong the life of the cleaner.

7. Store the cleaner in a dry place to avoid the risk of short circuit.

2

10

--