9

6. Pressure calibration

The level of the liquid is measured by measuring the pressure it causes compared to the to the

outside pressure. The pressure sensor can only operate if it is correctly calibrated. This means it

needs to be zero when the Aircomatic III is not filled with liquid. If there is any liquid in the

measurement tube, the Aircomatic will not read the actual pressure, this can cause it to stop too

early or too late.

To help check this the blue led bar can be used. To check the level, press-and-release the ‘O3’ button

until the blue bar is half full (this way you see when it displays the pressure). Now press-and-hold the

‘O3’ button for 10-15 seconds. The display will start displaying the measured pressure.

Each LED represents a certain value, with LED 8 indicating positive of negative pressure. The pressure

is acceptable when the following combinations are visible:

LED1 LED2 LED3-7 LED8

OFF OFF OFF Don’t care

ON OFF OFF Don’t care

OFF ON OFF Don’t care

All other values indicate that pressure is too high or too low

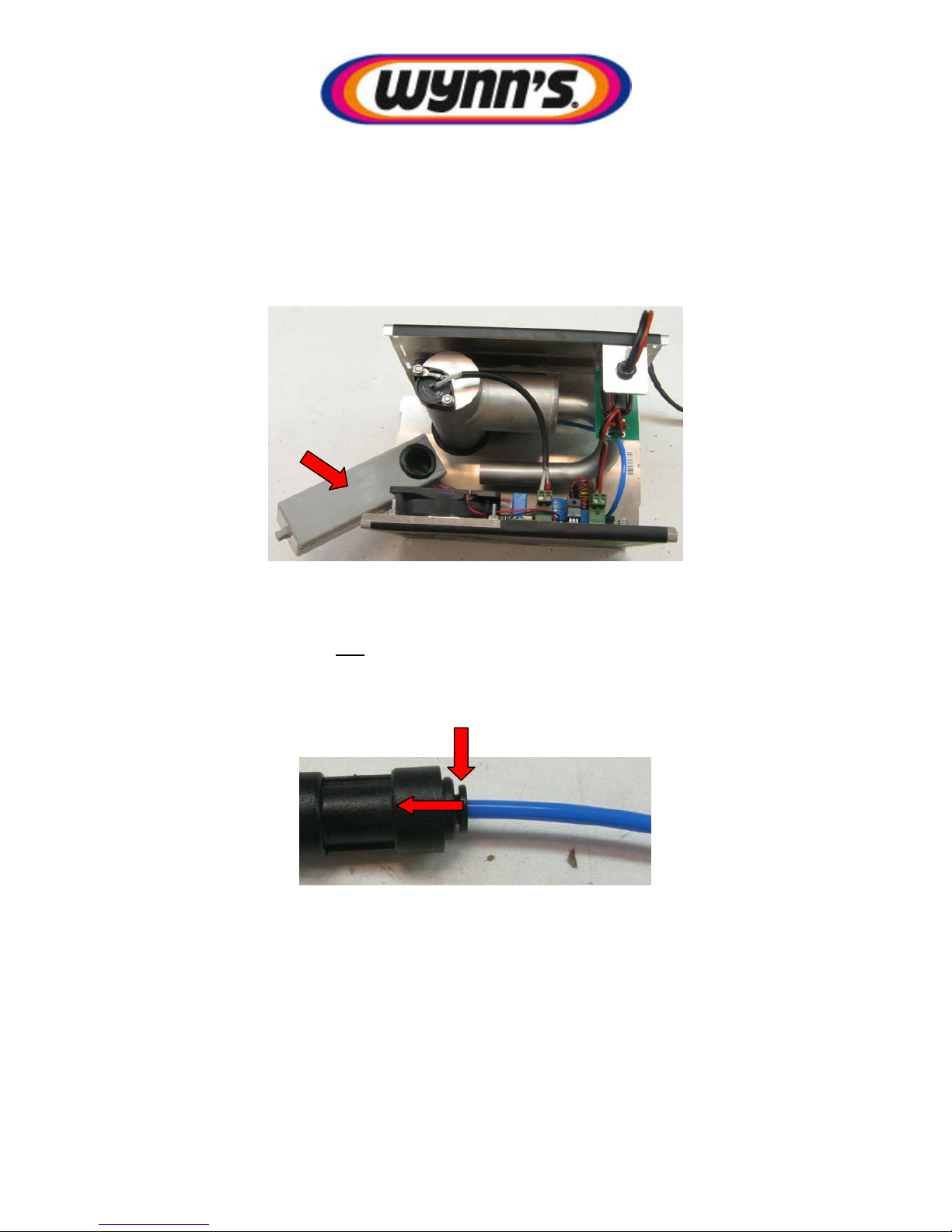

Before zeroing the pressure measurement you need to be sure that no liquid is in the measurement

tube. This can be checked by simply enabling this indication and shaking the product up-and-down,

and even upside down. If any liquid is present in the tube you should see the indication vary.

Once, the reading is stable this can be considered zero. By pressing-and-holding ‘Start/Stop’ button

for around 10 seconds the device is reset. The ‘High’ and ‘Low’ LEDs will blink, when the blue

‘Cleaning’ LED also blinks calibration has been performed successfully.