X – 60 Instructions Version 1.0 Page 3

X – 60 ASSEMBLY INSTRUCTIONS

FIRST THINGS FIRST

A) ASSUMPTIONS These instructions assume several things:

1. You have at least some experience building R/C cars. These

instructions are not written for a first-timer.

2. You have the usual assortment of R/C tools.

3. You have a Team Associated RC10 T4 rolling chassis, any model.

If you do not meet all the assumptions above, please contact us

immediately. Contact information is on Page 4.

WE WANT YOU TO HAVE A PLEASANT EXPERIENCE

BUILDING THIS KIT, AND HOPE YOU HAVE MANY

PLEASURABLE DAYS DRIVING YOUR NEW X- 60. Please

contact us with the slightest problem. We want to help. Talking

with the Family is so much more fun than work.

B) We suggest you have a clean, well-lighted work area with enough space

to simultaneously do three things: Work on the car; Store sub-

assemblies for later use; Store parts which will no longer be needed.

C) Before threading in screws, tap all holes with a 4-40 tap.

D) You will want to re-build many components, for example shocks, or to

disassemble some assemblies for inspection and cleaning. We include

no instructions for this – refer to your T4 manual.

E) All references to right and left are from the viewpoint of the driver sitting

in the car facing forward.

F) Throughout this manual the names of many parts are followed by a

number in parenthesis. This is the AE part number.

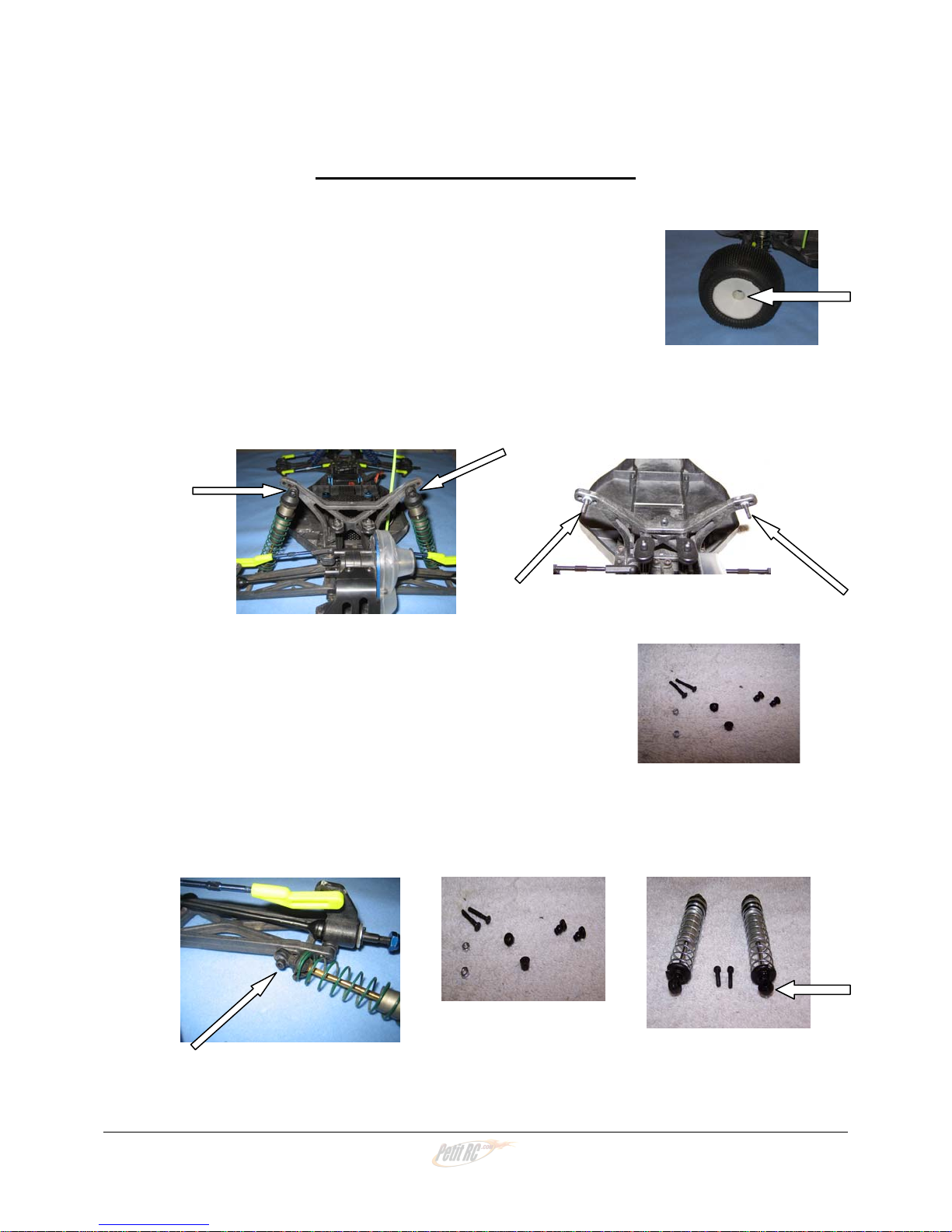

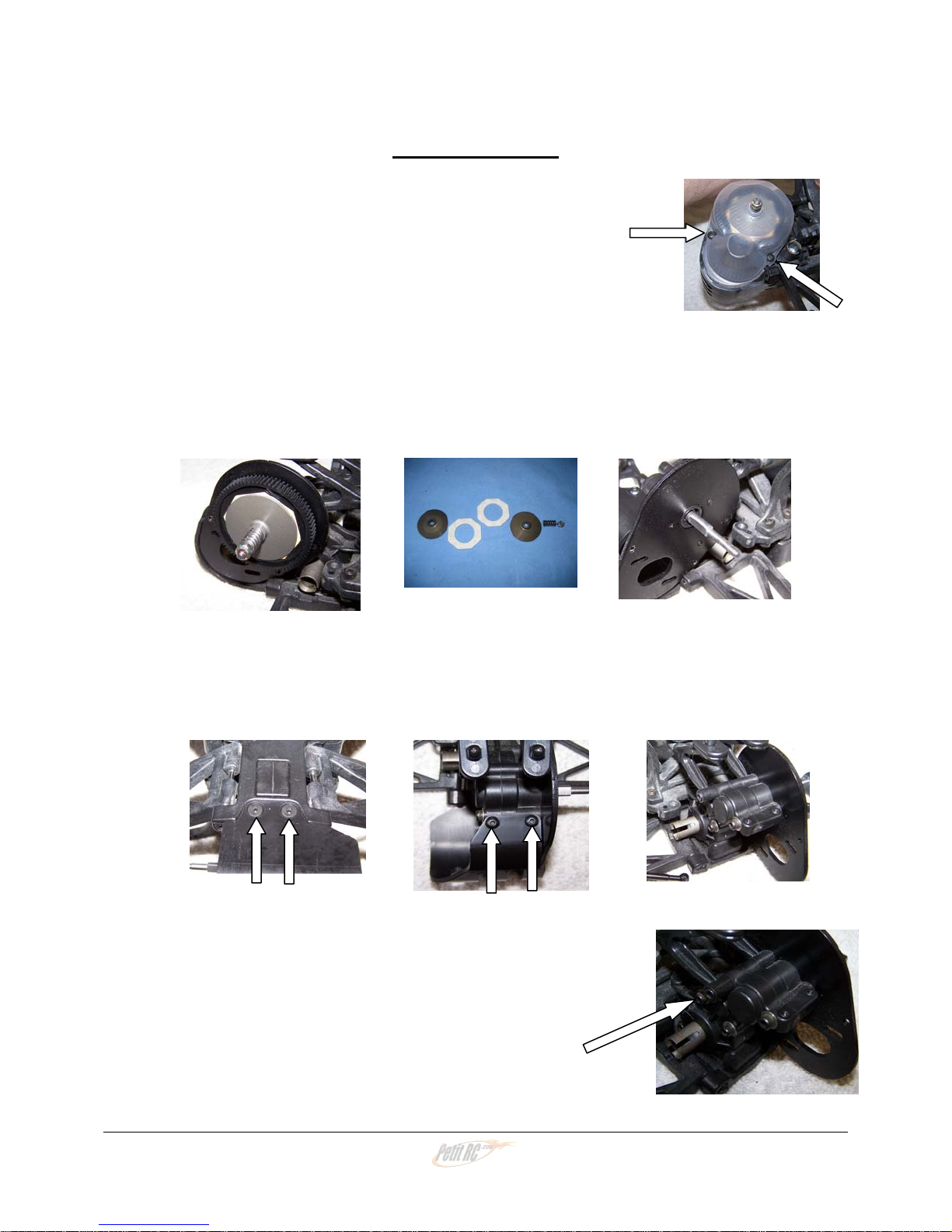

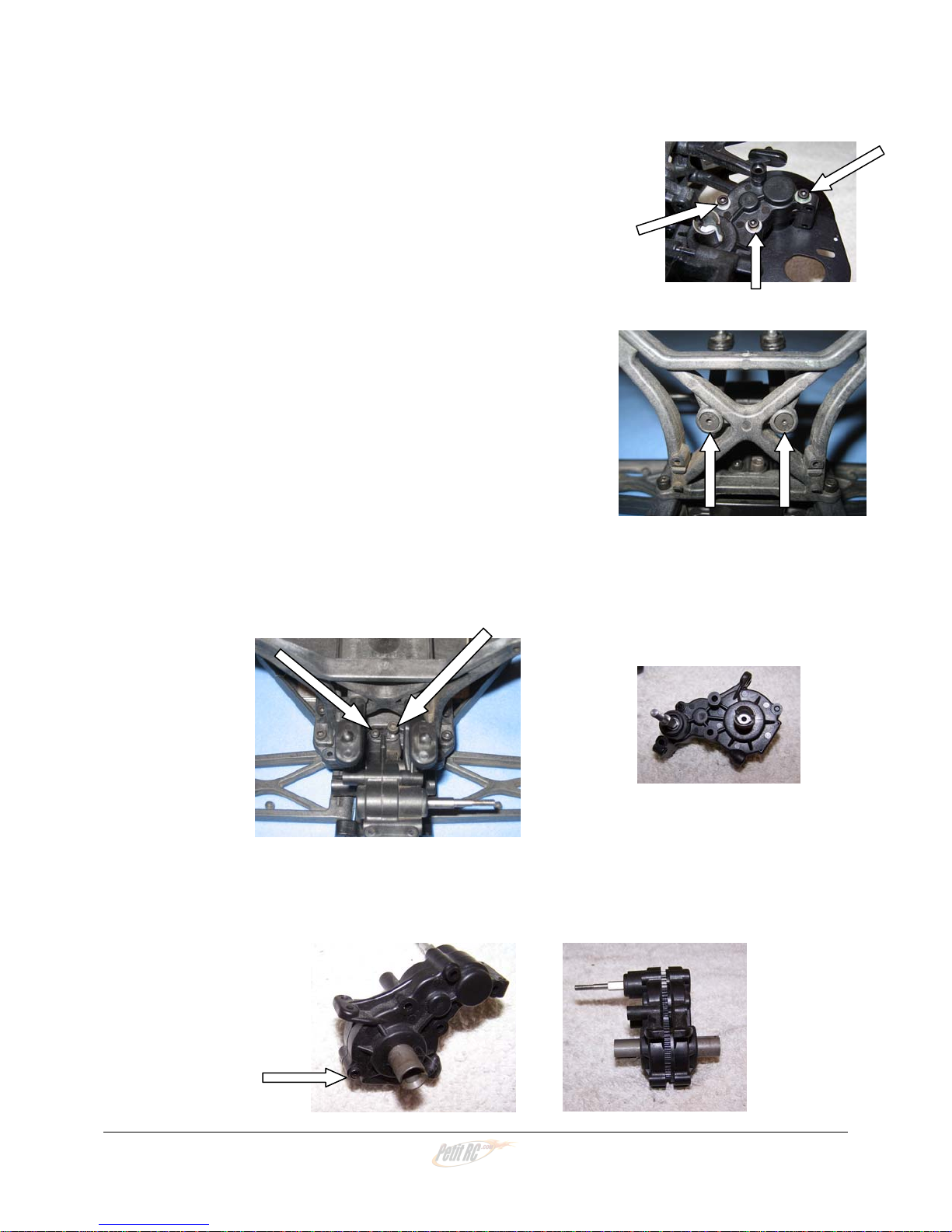

G) To photograph this manual, we assembled the truck several times. In

some photos, parts you have already assembled are “missing.” We

have done this deliberately so you may clearly see this particular step.

Follow the steps in order and you’ll get to the end quickly.

Most important, a big “thank you” to Chris Krieg, father of Team driver Alex,

who assembled his X – 60 at least three times to take the great photos and

wrote many of the instructions. Thank you, Chris!!!