Rev 1.2 | February, 2022 2

WET LOCATION DC ONLY XFL Flexible Linear LED Light Installation Instructions

PRIOR TO INSTALLATION

Water Resistant XFL products are easy to install in straight, curved and irregular spaces with

humid or outdoor conditions. Using high performance solid state lighting technology, light

output, color accuracy and LED brightness, XFL products can create warm and relaxing

environments or bright task lighting.

To maximize the lighting benefits of XFL, a few planning / design steps are recommended

before starting the installation process.

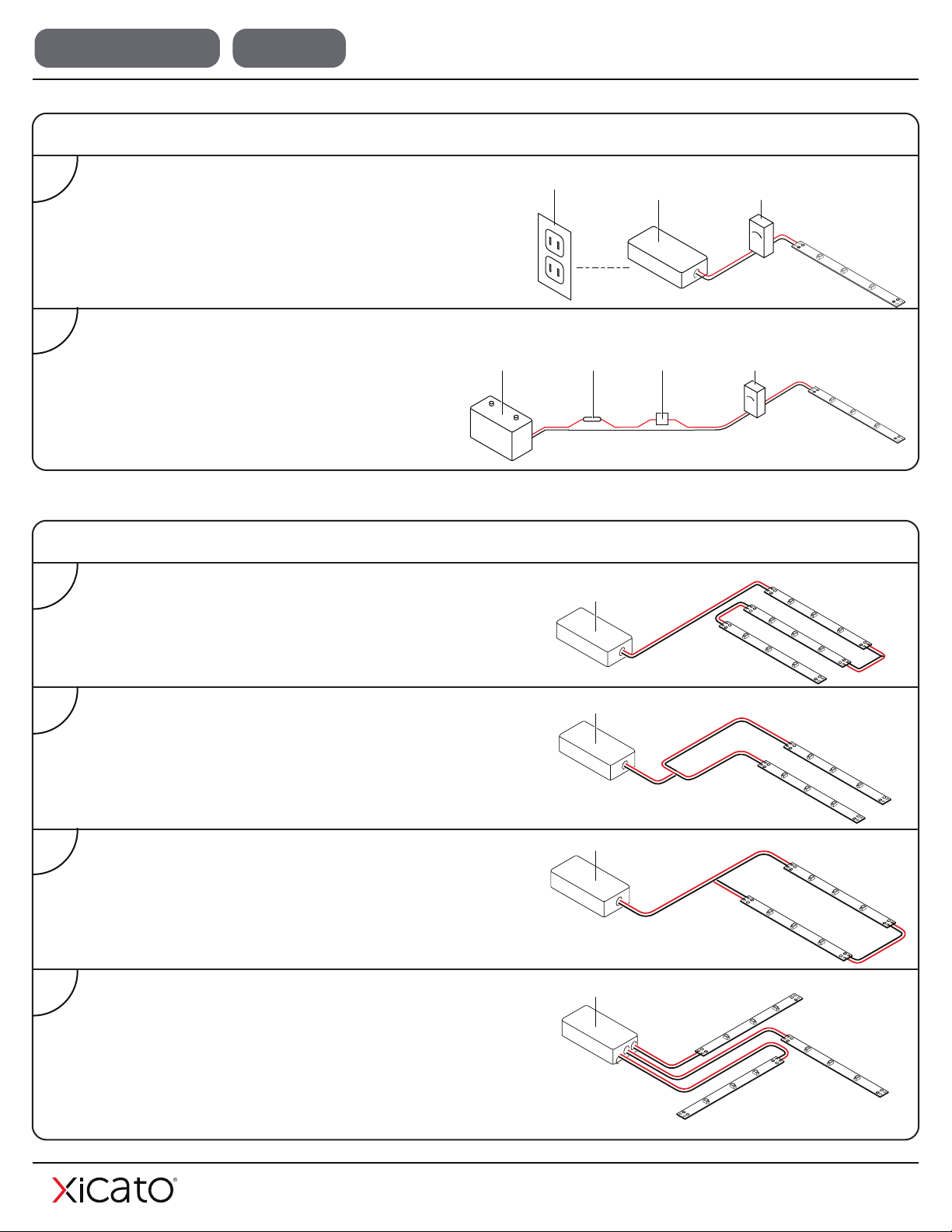

• Where will the power supply be located?

• How will the LED lighting be switched on and off?

• What is the best layout configuration for installation?

• How will wiring be run to the XFL product?

SAFETY AND HANDLING

It is important to read these guidelines completely to understand how the product works,

and how it can be configured, cut to size, connected and installed so you can design your

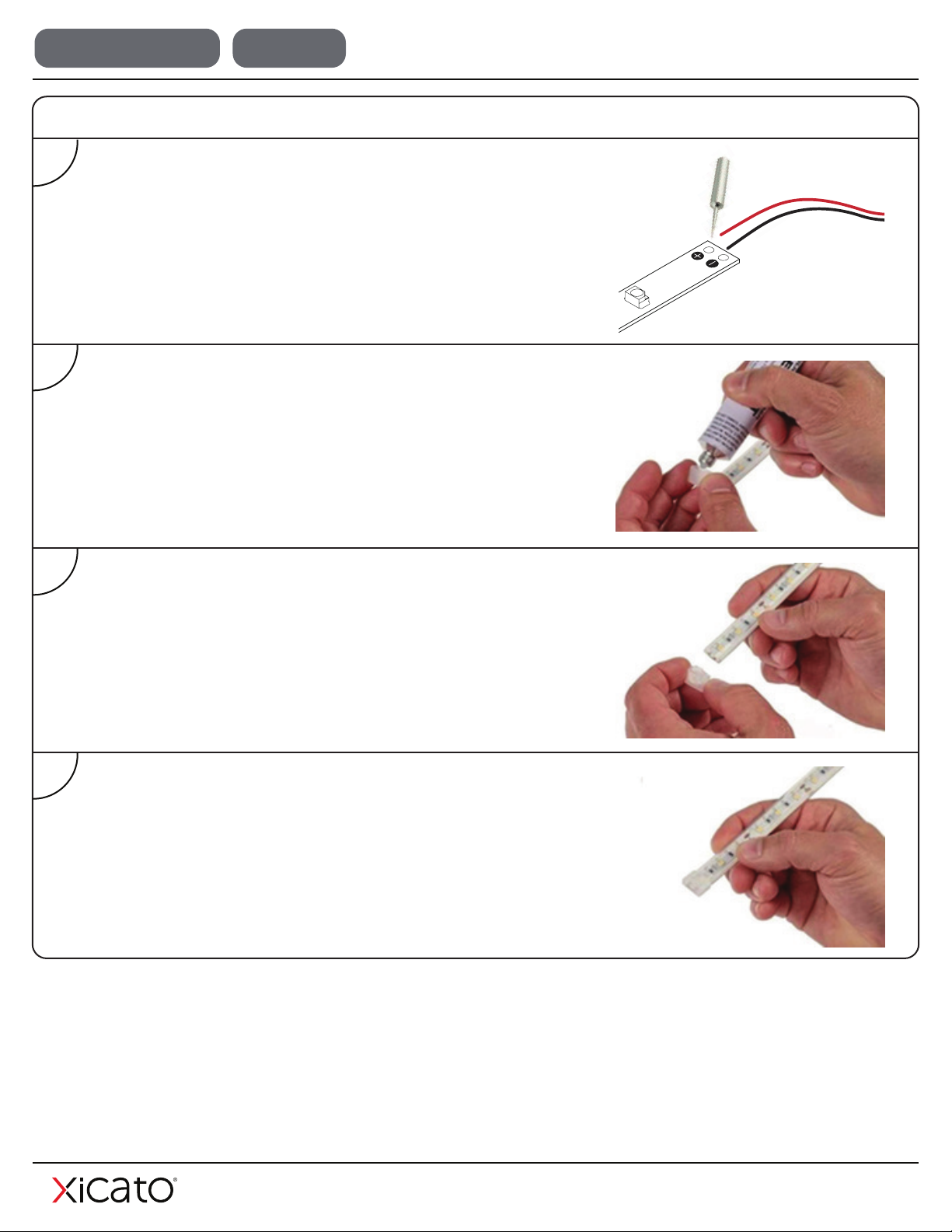

LED lighting layout. Installing flexible linear lighting is easy, however basic wiring skills such

as stripping, splicing, extending, and connecting wires are required.

This product should be installed and serviced in accordance with local and national

electrical code regulations by a qualified, licensed electrician. Failure to follow safety

warnings, and installation instructions will void the warranty for this product.

• Do not stare directly into LED lights when illuminated.

• Do not expose XFL product to direct or indirect moisture.

• Do not crimp light strip.

• Do not use sharp objects to handle XFL product

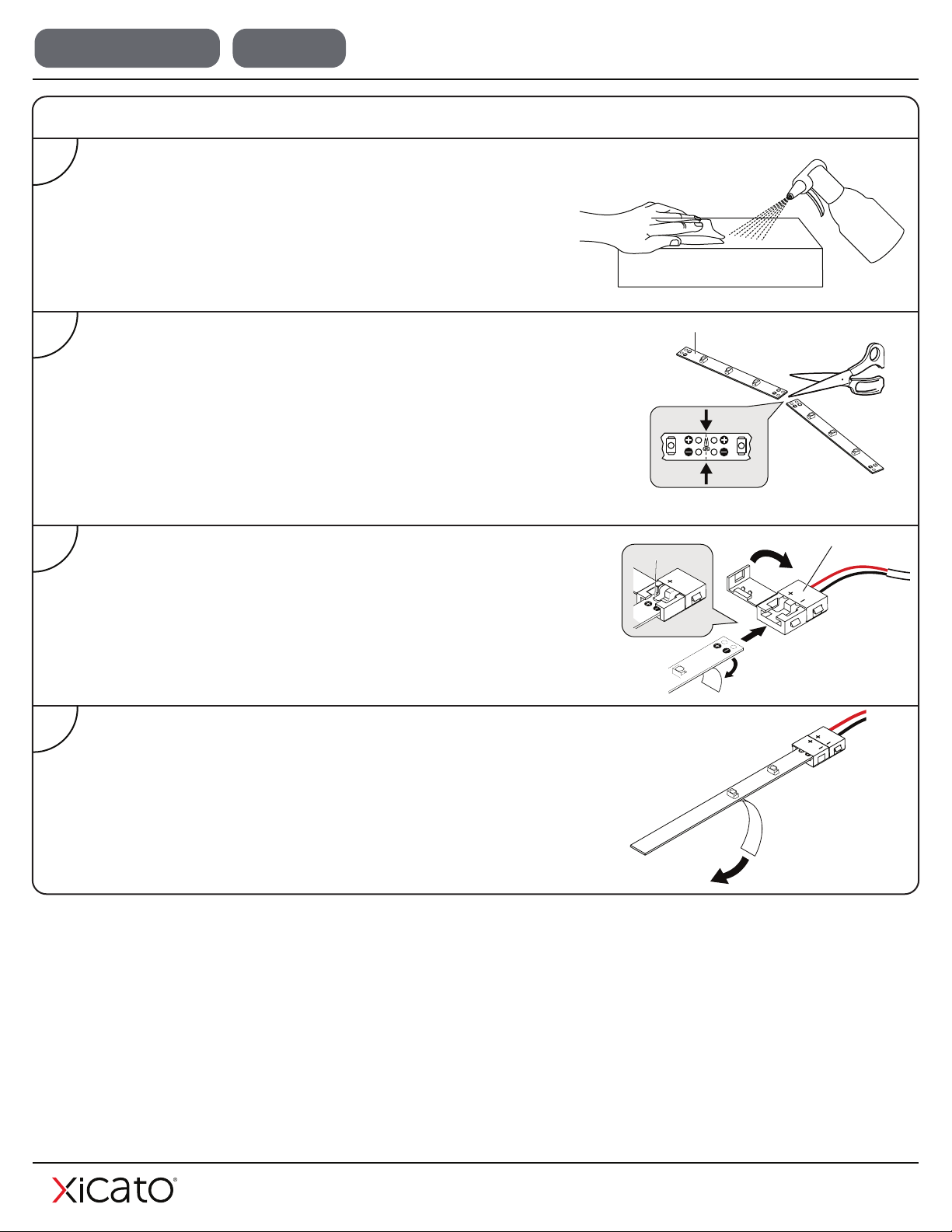

• Only use cutting tools as indicated by these instructions and product markers.

• Unused product should be properly placed and stored in an anti static bag.

• XFL products are designed to provide indirect, accent style lighting.

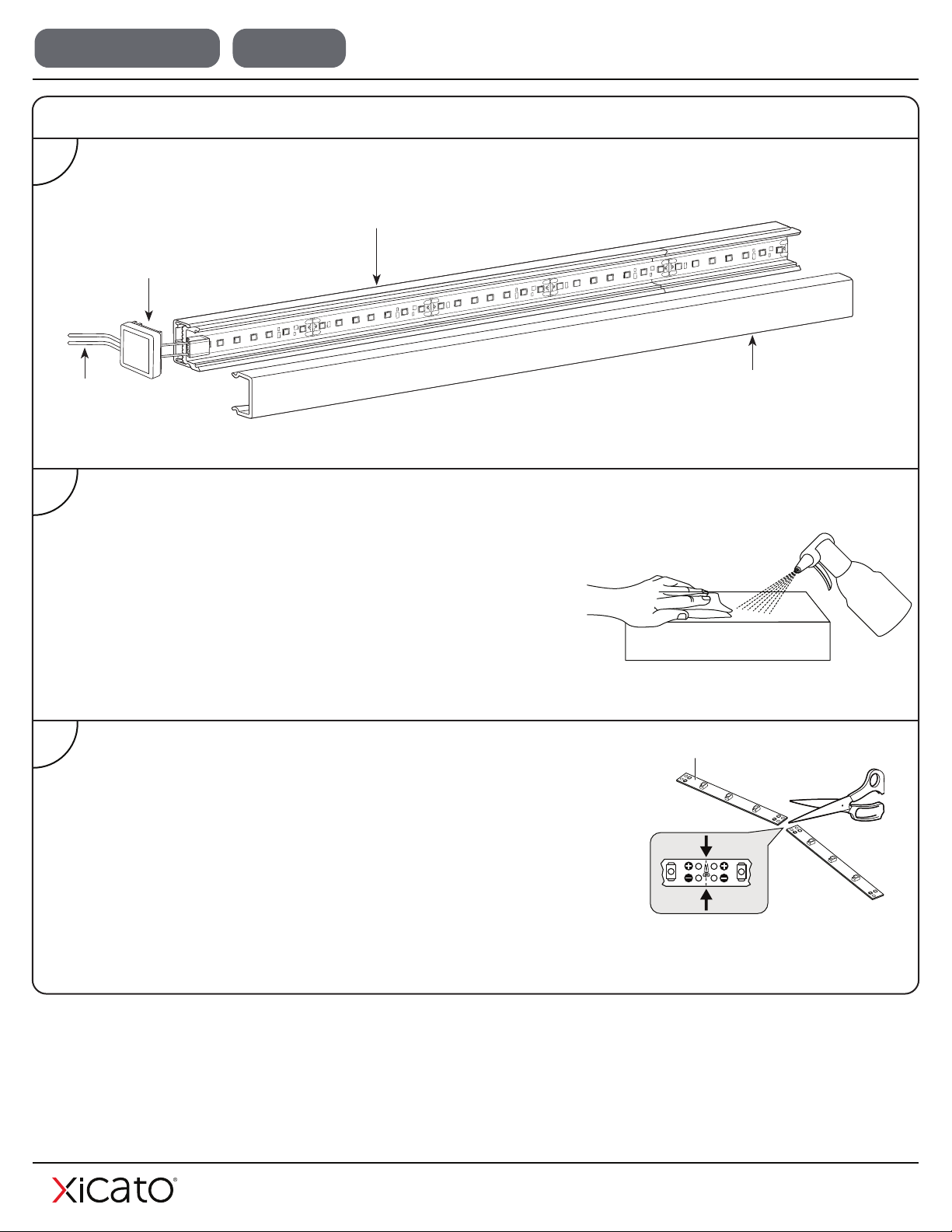

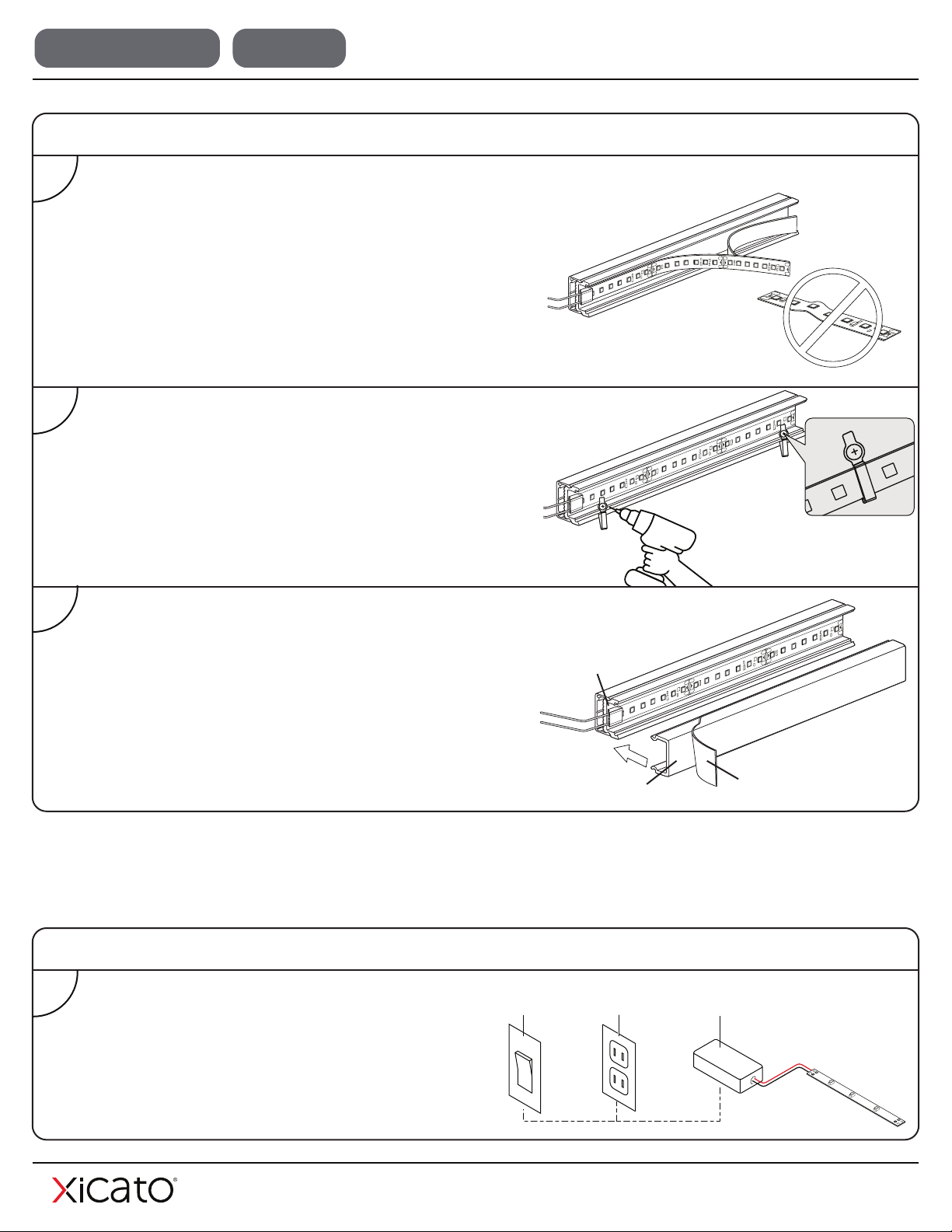

• XFL products can also be installed inside a channel with diffusing cover for direct and

indirect lighting. Instructions for installation in channel provided.