Manual

1. Maintenance List............................................................................................................................................. 1

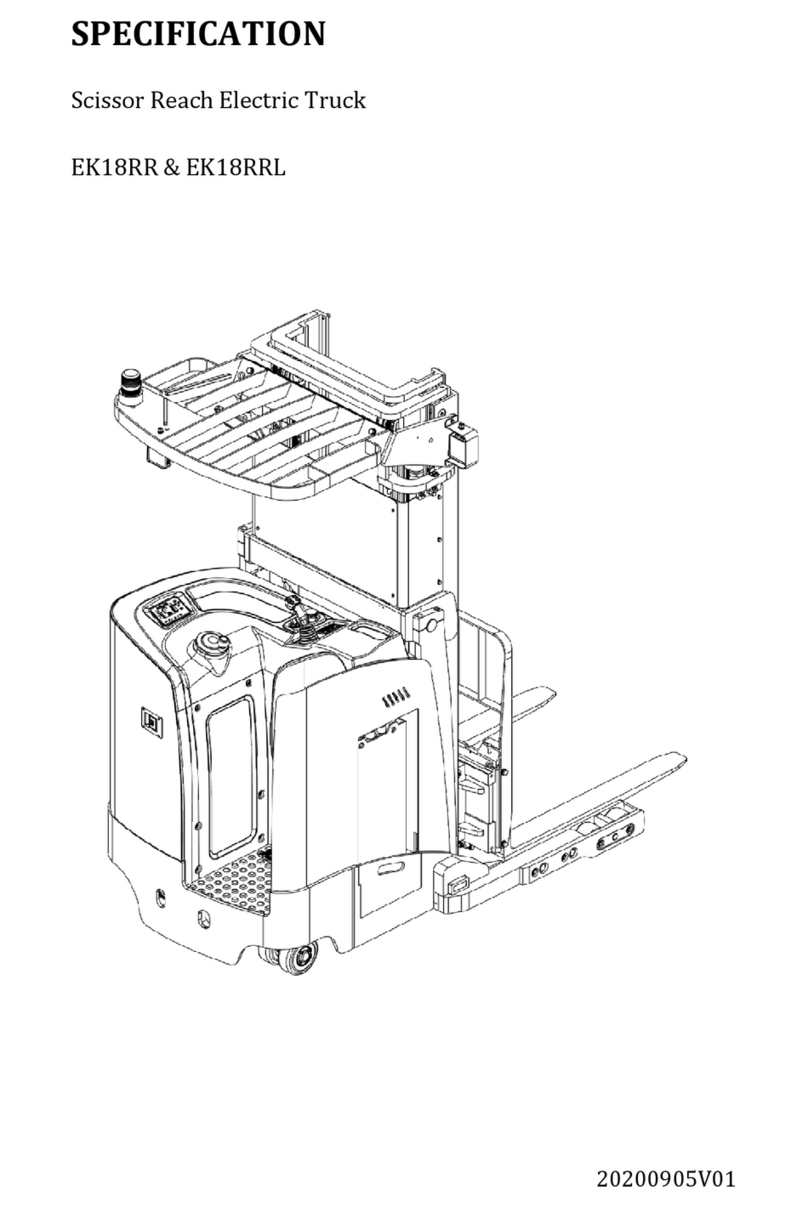

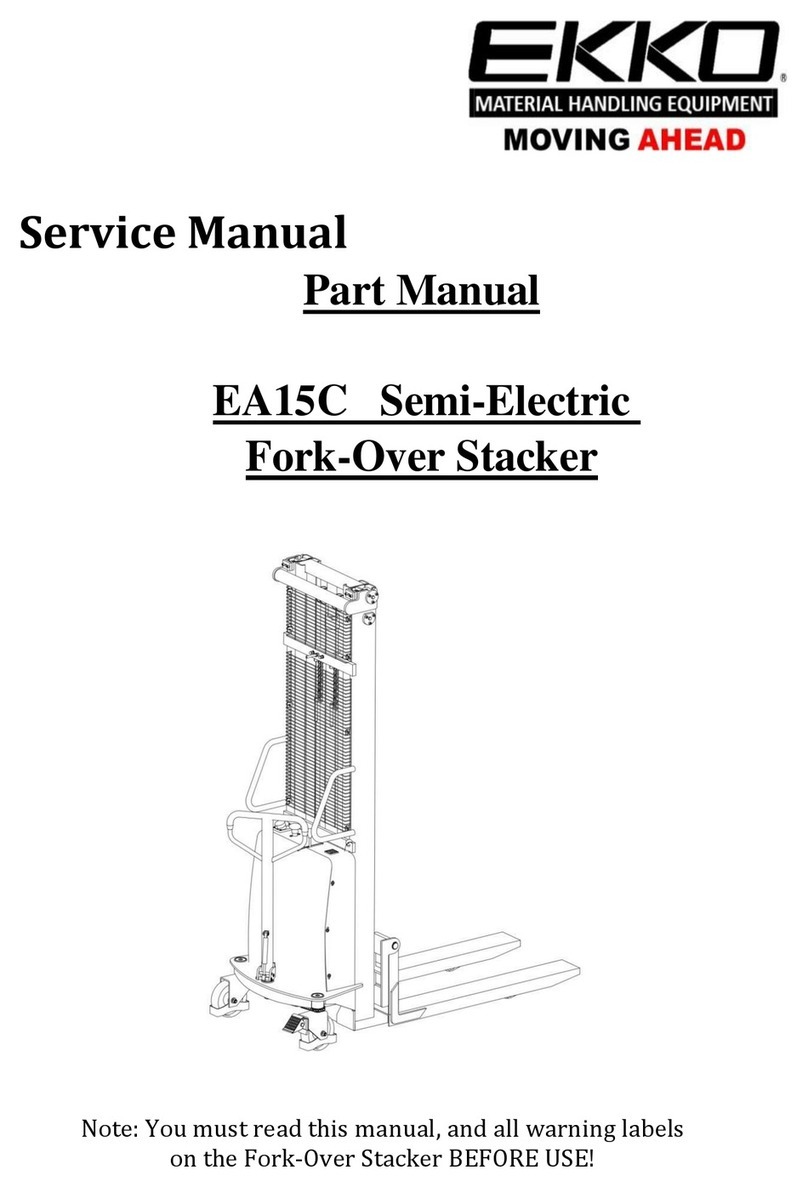

a. Overview of main components ............................................................................................................ 2

b. Lubrication point......................................................................................................................................... 4

c. Check and refill hydraulic oil.................................................................................................................. 4

d. Check the fuse ............................................................................................................................................... 6

2. Fault Analysis..................................................................................................................................................... 6

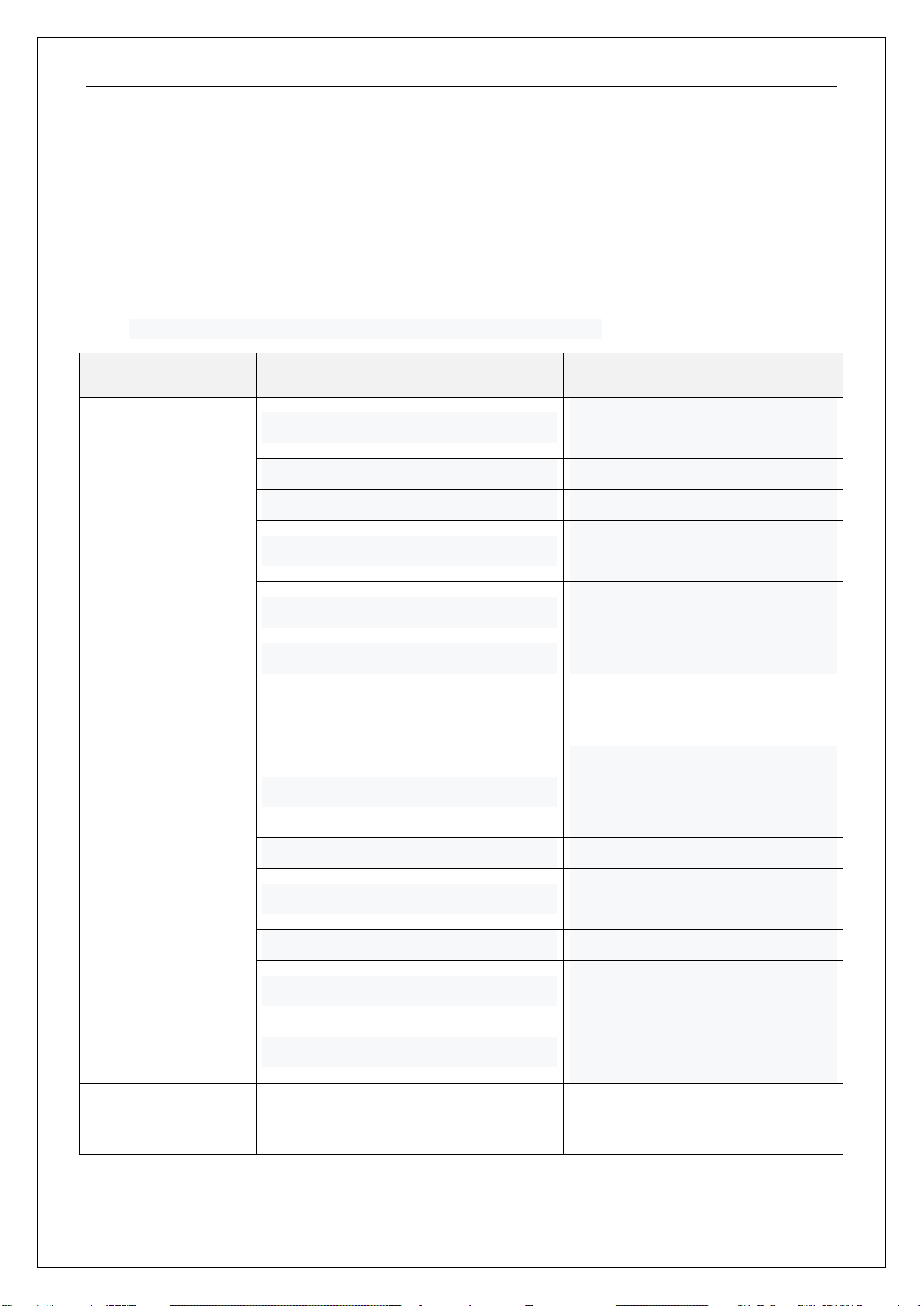

a. Common Fault analysis........................................................................................................................... 7

b. The fault code is displayed...................................................................................................................... 8

3. Wiring/circuit Diagram ..............................................................................................................................15

a Schematic diagram and wiring diagram ................................................................................................15

b Hydraulic circuit .............................................................................................................................................17

C Hydraulic Oil Inspection .............................................................................................................................18

4. Dis assembly of main parts ......................................................................................................................18

a. Removal of handle assembly .........................................................................................................18

b. Removal of electric control component.............................................................................................20

C. Hydraulic assembly Removal.................................................................................................... 22

d. Outer Mast ..................................................................................................28

e. Internal door frame assembly removed ............................................................................................22

f. Removing slide frame assembly ................................................................................................29

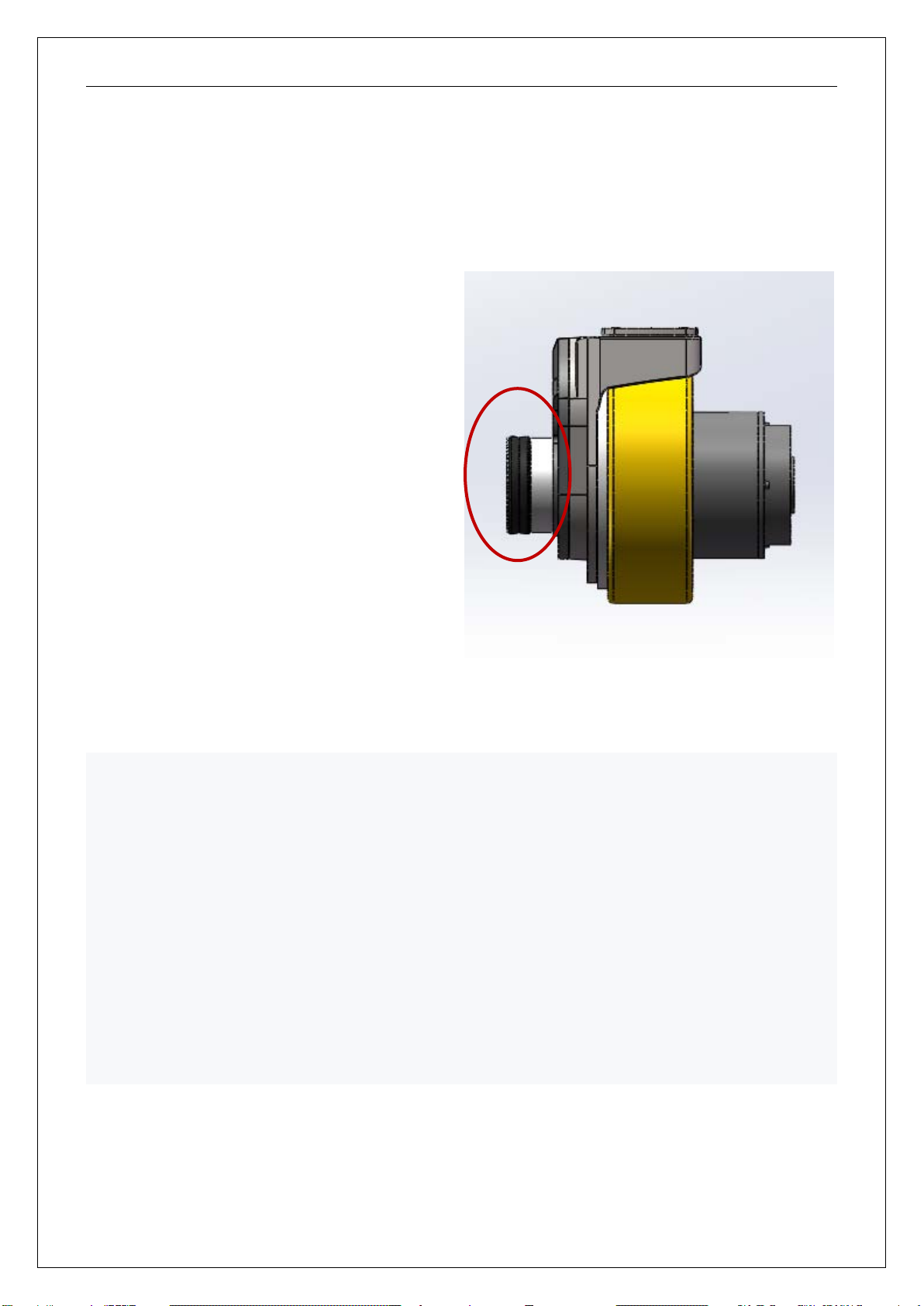

5. CURTIS handhold unit .................................................................................................................................30