HANGCHA XF Series User manual

XF series

Internal Combustion Counterbalanced 1.0t-X5.5t

Forklift Truck

1.5t-X5.5t XF Series Internal Combustion Counterbalanced

Forklift Truck

OPERATION MANUAL

HANGCHA GROUP CO., LTD.

Standard configuration model

Load center distance mm

(in)

500(19.7)

Model

CPD15-

CPD18-

CPD20-

CPD25-

CPD30-

Rated load lifting capacity

kg/ lb.

1500(3300)

1750(3850)

2000(4400)

2500(5500)

3000(6600)

Model

CPD35-

CPD40-

CPD45-

CPD50-

CPD55-

Rated load lifting capacity

kg/ lb.

3500(7700)

4000(8800)

4500(10000)

5000(11000)

5500(12000)

Load center distance mm

(in)

600(23.6)

Model

CPD15-

CPD18-

CPD20-

CPD25-

CPD30-

Rated load lifting capacity

kg/ lb.

1350(3000)

1600(3500)

1800(4000)

2250(5000)

2700(6000)

Model

CPD35-

CPD40-

CPD45-

CPD50-

CPD55-

Rated load lifting capacity

kg/ lb.

3200(7000)

3650(8000)

4000(9000)

4500(10000)

5000(11000)

CE model: Optional maximum lift height: 6000 mm

Caution

Bearing Capacity Chart

The chart shows the relationship

between the location of the load center

distance and the maximum load. Check

whether the load and the load center

distance are within the allowable range

of the Bearing Capacity Chart before

loading. If the load shape is irregular,

the heaviest part should be placed in

the center of the fork and close to the

backrest.

Load center

distance

Note: The model tonnage number displayed below is calculated at a load center distance

of 500mm.

©September 2022, HANGCHA GROUP CO., LTD.

Contents

I. Instructions for use........................................................................................................1

II. Forklift truck component names...................................................................................3

1. Instrumentation .............................................................................................................................3

2. Controls and switches .................................................................................................................12

3. Body and other parts ...................................................................................................................17

III. Safety regulations .....................................................................................................22

IV. Daily safety checks...................................................................................................28

V. Forklift truck structure and stability ...........................................................................32

VI. Operation..................................................................................................................35

1. Start.............................................................................................................................................35

2. Operation.....................................................................................................................................35

3. Loading .......................................................................................................................................36

4. Stacking.......................................................................................................................................37

5. Unstacking ..................................................................................................................................37

IX. Various signs and labels ...........................................................................................38

X. Lifting, handling and towing of the forklift truck .......................................................44

XI. OPS system description............................................................................................45

XII. Cab and overhead guard..........................................................................................47

XIII. Precautions for use of the LPG forklift truck..........................................................48

XIV. How to use and maintain the lead-acid battery .......................................................60

XV. Use, installation and safety rules for accessories......................................................64

XVI. Optional configuration of driver's seat handrail for fingertip control.......................67

1

I. Instructions for use

In order to ensure personal and equipment safety, the driver should obey the following Precautions:

1. Only drivers with proper training and a valid license should operate the vehicle.

2. Check each control and alarm device before driving, if any damage or defects are found they should

be repaired before operation.

3. The load should not exceed the specified value when handling; the forks should be fully inserted

into the load so that it is uniformly positioned on the fork; do not use a single fork to lift cargo.

4. Start, turn, drive, brake and stop smoothly; slow down on wet or slippery roads when steering.

5. Loads should be placed as low as possible, and the mast should tilt backward when driving.

6. Be careful when driving on ramps; move forward when driving up gradients greater than one in ten

and move back when driving down ramps; do not turn when driving up or down ramps; do not carry

out loading and unloading operations when the forklift is in motion.

7. Pay attention to pedestrians, barriers, and bumpy surfaces when driving and be aware of the upper

clearance of the forklift truck.

8. Do not stand on the forks and do not carry passengers.

9. Do not stand under the forks or walk under the forks.

10. Do not operate the truck and its accessories from anywhere except the driver’s seat.

11. Do not handle unsecured or loosely stacked cargo and be careful when handling large cargos.

12. Protect cargo on high lifting forklift trucks with a lift height of more than 3m from falling down and

take preventive measures if necessary.

13. Try to tilt the mast backward when the high lifting forklift truck is in operation and tilt forward

within the minimum range during loading and unloading operations.

14. When driving on wharfs or temporary decking, you should be extra careful and drive slowly.

15. The driver should not stay in the truck and should shut down the engine when refuelling; keep

sources of ignition away when checking the battery or fuel tank level.

16. When a forklift truck with accessories is idling, it should be operated in the same manner as a

loaded forklift truck.

17. Drop the forks to the ground, switch the gear lever to the neutral position, pull the parking brake

device properly, shut down the engine, and disconnect the power when leaving the truck. Engage the

parking brake device properly when parking on ramps, place cushion blocks under the wheels when

parking for a long time.

18. In case of a sudden fault when lifting cargo or driving on gradients, causing leakage of storage

battery electrolyte, hydraulic oil and brake fluid, or a flat tire etc., personnel should be organized for

repair immediately, the truck should be kept in a safe condition, and professional maintenance

personnel or the seller should be contacted.

19. Noise and vibration will be generated during installation and assembly processes; please choose

proper tools and assembly methods to reduce the impact of noise pollution on the environment.

20. The forklift truck must not be used in plant areas; the working surface should be solid and flat

cement pavement, asphalt pavement or concrete pavement. When there is snow, ice, water or other

foreign matter on the road, the truck can only be used after it has been fully cleared away; otherwise,

the truck is likely to lose control, resulting in an accident.

21. In the event of a breakdown, the truck should be first moved to a place where it does not obstruct

traffic. If the breakdown is caused by the brake system or steering system, the truck should be carried

2

away with a proper carrier loader (see the vehicle handling content); if it is caused by other reasons,

the truck should be towed with an appropriate vehicle; tow rope should be fixed outside the truck

body when towing. Obey traffic rules when towing a truck on the highway.

22. Do not operate the forklift truck or carry cargo after disassembling the internal combustion engine

hood, water tank cover plate, overhead guard, mast backrest or other protective devices.

23. There should be sufficient lighting in the truck working area. Turn on the head lights when working

at night and there should be sufficient lighting in the work area.

24.Do not conduct side shift operations when a forklift truck with automatic adjustable distance forks

is loaded to protect the forklift truck from losing balance and damaging components.

25. The 5T-10t forklift truck is provided with an energy accumulator, which can provide at least one

emergency braking operation after the forklift truck has been shut down; in order to ensure your

safety, please carefully read and strictly implement operations related to the energy accumulator in

the manual.

26. Please do not tilt the mast forward or backward or lift the mast to the extreme position during

idling where possible before the temperature of the hydraulic oil rises.

27. Do not revise or modify the forklift truck without the written approval of the forklift truck

manufacturer in advance; otherwise, it may affect the rated load and stability or safe operations. This

includes: Assembly and disassembly of brake, steering, visibility devices and accessories. When the

forklift truck manufacturer agrees to revise or modify the truck, he/she should also agree to update

and properly revise the bearing nameplate, label, and operation and maintenance manual.

28. If the user refits the forklift truck, it may introduce hazards or risks that the manufacturer did not

consider, thus the existing forklift truck risk assessment will become invalid.

Forklift truck refitting outside Europe should conform to regional requirements (see ISO/TS 3691-8).

3

II. Forklift truck component names

1. Fork

2. Backrest

3. Lifting hydraulic

cylinder

4. Mast

5. Steering wheel

6. Overhead guard

7. Counterweight

8. Driver’s seat

9. Rear wheel

10. Frame

11. Hood

12. Tilt cylinder

13. Front wheel

1. Instrumentation

Diesel Engine Homepage (Xinchai / Kubota)

Key 4

Key 3

Key 2

Key 1

1

2

3

4

6

57

8

9

10

11

12

13

4

GCT Engine Homepage

Key 4

Key 3

Key 2

Key 1

H11/ H12 Engine Homepage

Key 4

Key 3

Key 2

Key 1

A. Instrument indicator lights

Water temperature gauge

When the ignition key switch is in the ┃ (open)

position, the water temperature gauge is active,

displaying the engine coolant temperature; in

normal operation the LCD will show that it is

within the range 40℃-110℃.

Caution

Stop operation immediately and reduce

engine speed to cool down the engine and

then stop the engine when the gauge is in the

red area. Check the coolant level is sufficient

and whether the fan belt is tight.

Fuel gauge

When the ignition key switch is in the ┃ (open)

position, the fuel gauge will display the

approximate fuel quantity of the fuel tank.

It is recommended to fill up the fuel tank every

day after work.

Stopwatch

When the ignition key switch is in the ┃ (open)

5

position, the stopwatch will start running. The

stopwatch reading will increase by one digit for

every hour of operation.

The stopwatch displays the cumulative working

hours of the forklift truck.

Caution

After the cumulative hours reaches 100h

(the factory default interval is 100h, and it

can be adjusted) displayed on the

stopwatch, the “wrench” icon will flash for 1

hour and prompt that the forklift truck

needs to be serviced. See monthly

maintenance after the first flash. See the

information about maintenance cycle

schedule in detail for each cycle. The specific

flash time depends on the actual situation.

Charging indicator light

The light displays the battery charge status,

turns on when the starting switch is in the ┃

(open) position, and turns off when the engine

is started.

Caution

If the light continues to turn on or flash

during operation, it indicates that the

charging is abnormal and immediate

inspection is required.

Preheat indicator light [diesel forklift truck]

The light turns on for a short period after the

switch is moved to the ┃ (open) position, and

the switch can be moved to the (start)

position for starting after the light turns off.

Engine oil pressure alarm indicator light

The light indicates the pressure of engine

lubricating oil.

Caution

If the light continues to turn on or flash

during operation, it indicates that the oil

pressure is less than 0.05MPa and immediate

inspection is required.

Parking indicator light

When the light turns on, it indicates that the

parking brake is applied. In order to drive the

truck, the parking brake lever (e.g., hand brake

lever) should be released; at that time, the

light turns off.

Warning

Driving the truck when the light is on may

cause damage to the engine, drive system

and other parts.

Oil-water separator indicator light [diesel

forklift truck]

The light turns on when the water level reaches

a certain level when the engine is running.

If the light continues to turn on or flash when

the engine runs, the engine should be shut

down immediately to discharge water.

Caution

If operation is continued after the light turns on, the

fuel oil injection pump may be damaged.

6

Neutral start indicator light

When the truck is temporarily stopped, the

direction lever should be in the neutral

position; at that time, the light turns on.

The truck can only be started when it is in

neutral.

The truck must not be in the neutral position

when driving downhill.

Gearbox oil temperature alarm light [hydraulic

forklift]

When the engine is running and the gearbox

oil temperature exceeds the normal range

(60℃-120℃), the alarm light will turn on.

Caution

If the alarm light turns on, please stop

operation immediately and reduce engine

speed to cool down until the light turns off.

Otherwise, the oil quantity should be checked

or other inspections should be conducted.

Safety belt alarm indicator light (optional)

When the start key is in the “┃”, position, the

engine is not started and the driver is not on

the driver's seat. If the safety belt is not

fastened properly, the safety belt alarm

indicator light will turn on.

If the safety belt is not fastened or loose when

the driver is operating the vehicle, the buzzer

alarm will sound and the safety belt alarm

indicator light will turn on at the same time.

This is to remind the driver to safely park and

refasten the safety belt; then, the buzzer alarm

will stop and the safety belt alarm indicator

light will turn off.

Air cleaner alarm indicator light

When the light turns on, it indicates that the

air cleaner of the air intake system is blocked

and the truck has to be stopped to clean the air

cleaner.

Engine fault indicator light [for forklift trucks

with an electronically controlled engine]

When the light turns on, it indicates that there

is a fault and the truck has to be stopped

immediately.

Maintenance personnel can press the right key

of the instrument to check or connect the ECU

diagnosis interface with the diagnostic

equipment to read the fault code information

stored in the ECU.

Low brake pressure alarm indicator light

The indicator light in the 1.0t-X5.0t forklift

truck is not operative.

OPS indicator light

When the light turns on, it indicates that the

driver is not on the driver's seat or is not sitting

properly.

7

Gasoline engine / LPG engine: H1, H3

Engine fuel: Gasoline

Engine fuel: LPG

ECO: Low LPG capacity prompts

that it should be supplemented

soon.

The fault diagnosis tester is

connected with the indicator

light

Regen indicator light

There are three kinds of working mode: Driving

regen, parking regen, and service regen

(aftersales solution).

In the first case, the regen indicator light turns

on normally and is in the regen working status.

At that time, manual intervention is not

required and normal operation can be

maintained. The light will automatically turn off

after the regen prompt, which also indicates

that the treatment of particulate matters is

completed.

The driver should reduce light running time as

much as possible to increase the exhaust

temperature and shorten the regen time.

In the second case, it prompts that the parking

regen should be started.

Start parking regen (see operating instructions

for instrument keys) after meeting parking

regen conditions.

Parking regen conditions:

①The forklift truck is parked on a

well-ventilated flat road.

②Pull the hand brake.

③Release the accelerator pedal.

④Keep the direction lever in the

neutral position (gear N).

⑤Warm up the forklift truck until

the water temperature reaches 70℃.

⑥Install the hazard Warning sign

near the exhaust port.

Caution

Parking regen: The parking status is not

suitable for heat dissipation. Stay away from

inflammables and keep a safe distance from

people.

The driver should pay attention to safety,

should not leave the site, and should monitor

the engine conditions during regen.

The driver should not stop the engine during

regen as this is likely to cause a DPF fault.

Warning

In case of emergency, parking regen is

inhibited, and only one of conditions

②③④ to exit parking regen needs to be

met.

The regen indicator light turns on when driving

and the forklift truck can continue to be used

normally or can be driven to a safe position for

parking regen.

If the regen indicator light turns on when

driving and the engine fault indicator light

turns on as well, maintenance personnel or

aftersales staff for the plant area should be

contacted to check the engine fault code. Start

the parking regen after confirming that there is

no other fault.

Caution

If the two indicator lights turn on and there is

no parking regen within 2h, the DPF is likely to

be blocked, the parking regen will fail to start,

and DPF may be damaged, causing

maintenance expenses.

H7/ H8

diesel

engine

Flash

Fault code

SPN:5270 FMI:15

W97,

W98,

W99

Diesel

engine

Flash

Fault code

GASO

LINE

LPG

HDM

3000

8

SPN:3701 FMI:15

At the end of parking regen, the light will

automatically turn off; the engine can be shut

down after waiting for 2-3min until the engine

restores to normal idling.

In the third case, service regen.

H7/ H8

diesel

engine

Flash

Fault code

SPN:50261 FMI:15

W97,

W98,

W99

Diesel

engine

Flash

Fault code

SPN:3701 FMI:16

When the DPF has been severely blocked, the

engine has reduced power and torque, and the

forklift truck does not work normally, aftersales

staff should be contacted for service regen.

Exhaust system fault indicator light

If the EATS has a fault or exceeds the

designated operating parameters, the engine

fault light should turn on at the same time.

Inhibit indicator light

When the light turns on, it indicates that the

regen status of the engine is restricted and

driving regen or parking regen is inhibited.

Caution

When working in an environment that is not

suitable for DPF regeneration, turn on the

inhibit mode. After leaving, release the inhibit

mode promptly so that active regeneration

can continue.

Warning

If the active regen has been inhibited, the

exhaust filter and exhaust will become

blocked and the working performance of the

forklift truck will be degraded until the engine

fault indicator light is activated.

High exhaust temperature indicator light

Caution

Light on: Reminds the driver that the regen

process causes high exhaust temperature and

to pay attention to safety.

9

B. Operating instructions for instrument keys

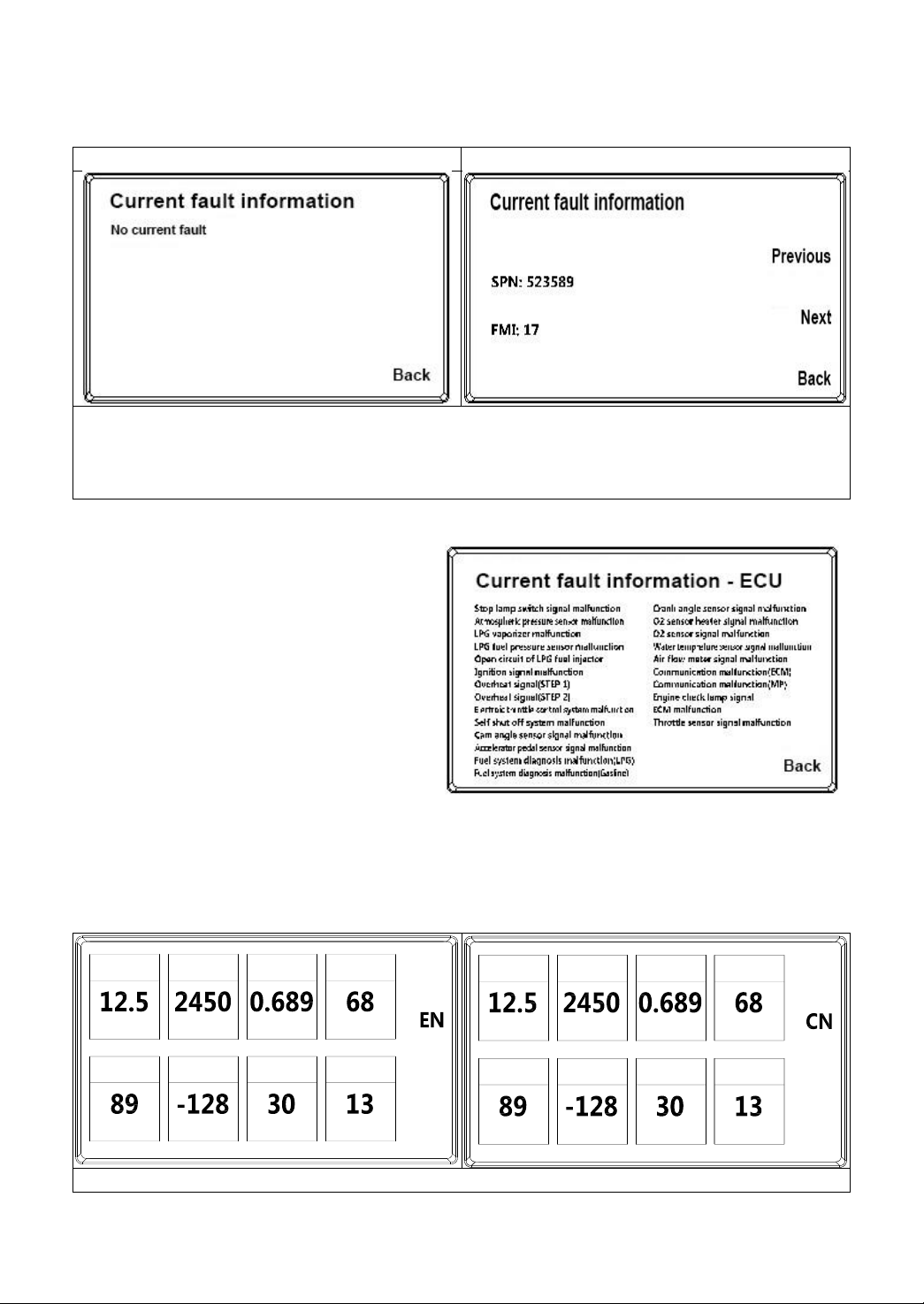

B.1 Engine fault information display page

(1) Diesel engine (Kubota/Xinchai) and H11/H12 engine

No faults

Fault present

① Enter the engine fault information display page: Homepage=》Key 4

② Fault query page selection: Press key 2 or key 3 again for page selection (the page selection key is

not displayed when there is no fault)

③ Back to the homepage: Press Key 1 to return to the homepage

(2) GCT engine

① Enter the engine fault information

display page:

Homepage=》Key 4

② Back to the homepage:

Press Key 1 to return to the homepage

Note: GCT engine fault information

(English) will be directly displayed

according to fault content.

B.2 Forklift truck operating parameters and Chinese and English interface switch

① Enter the forklift truck operating parameter display page: Homepage=》Key 2 or Key 3

② Language switch: Press Key 3 again to switch language (CN/EN)

③ Back to the homepage: Press Key 1 to return to the homepage

Diesel engine (Kubota/Xinchai)

蓄电池电压 发动机转速 机油压力 转速负载

Ash 负载 SOOT 负载 进气温度 行驶速度

%

VDC r/min

℃km/h

%

Bar

%

Battary

Voltage

Ash

Load

Engine

Speed

SOOT

Load

Oil

Pressure

Intake Air

Temperature

Load @

RPM

Vehicle

Speed

%

VDC r/min

℃km/h

%

Bar

%

10

GCT engine

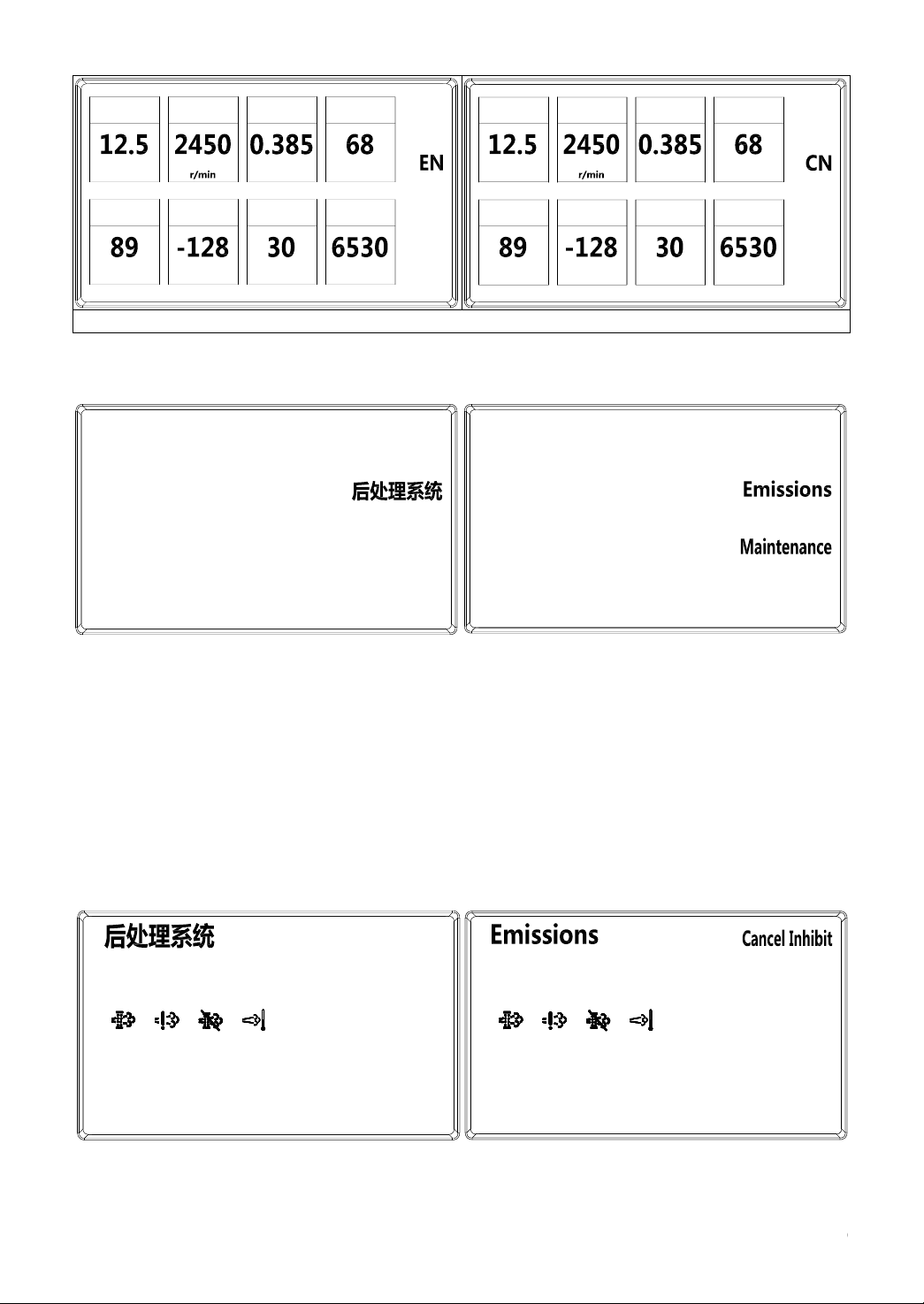

B.3 Setting page

(1) Operations on the setting page

⚫Enter the setting page: Homepage=》Key 1

⚫Enter the maintenance page: Homepage=》 Key 1=》 Key 2, enter the maintenance repair

page

⚫Enter the emissions system setting page: Homepage=》 Key 1=》 Key 3, enter the emissions

system setting page

⚫Enter the advanced setting page: Homepage=》 Key 1=》 Key 4, enter the advanced setting

maintenance personnel password input page

⚫Back to the homepage: Press Key 1 to return to the homepage

(2) DPF emissions function setting page (diesel engine)

Cancel inhibit: Press Key 4 and enable the DPF automatic regen function

Inhibit: Press Key 3 and disable the DPF automatic regen function

%

VDC

?℃us

%

kg/cm2

蓄电池电压

A / F

Alpha

发动机转速

点火正时

LPG 压力

进气温度

充电效率

喷射脉宽

Battary

Voltage

A / F

Alpha

Engine

Speed

Ignition

Timing

LPG Fuel

Pressure

Intake Air

Temperature

Charging

Efficiency

Injection

Pluse Width

%

VDC

?℃us

%

kg/cm2

保养提醒

返回

高级设置

Back

Setting

请求再生

返回

禁止再生

取消禁止

Regen

Back

Inhibit

11

Regen: Press Key 2 and enable the DPF parking regen.

Back: Press Key 1 to return to the setting page

(3) Maintenance repair page

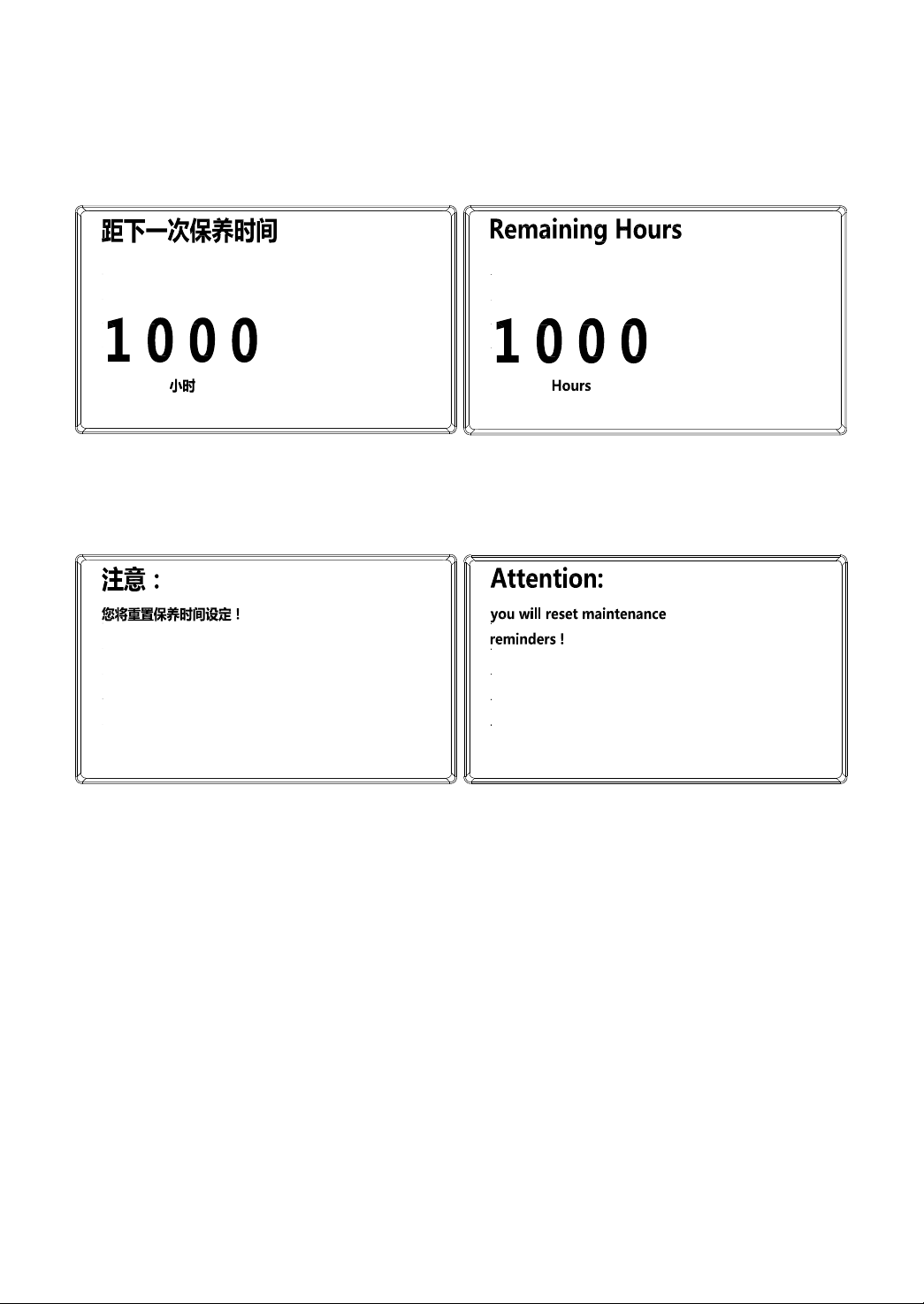

a. Remaining hours query page

The remaining hours can be observed on the page

Reset: Press Key 2 to be redirected to the maintenance hour reset page and reset the remaining

hours to the set initial value (maintenance cycle interval).

Back to the setting page: Press Key 1

b. Maintenance hour reset page

Reset: Press Key 2 to confirm reset and automatically return to the maintenance query page if the reset

confirmation is successful.

Back to the setting page: Press Key 1 to return to the setting page

重置

返回

Reset

Back

确定

返回

Confirm

Back

12

2. Controls and switches

Control and Switch Diagram of the 1.0T~x5.5t Forklift Truck

1. Steering wheel

2. Horn

3. Combination light switch

4. Ignition key switch

5. Lifting lever

6. Tilt lever

7. Cup holder

8. Instrument

9. Rocker switch

10. Accelerator pedal

11. Brake pedal

12. Inching pedal

13. Hand brake lever

14. Steering wheel adjustment switch

15. Direction lever

16. Brake fluid flap

17.Emergency power-off switch

(optional)

12365

47

8

9

12 11

10

14

16

15

13

13

Steering wheel [1]

Controls the driving direction of the truck

Anticlockwise rotation

turns the truck to the left; clockwise rotation

turns the truck to the right.

Warning

The forklift is equipped with a fully hydraulic

steering mechanism. When the engine shuts

down, it will be very difficult to steer the

forklift. Before turning again, the engine must

be restarted immediately.

Horn button [2]

The horn will sound by pressing the horn

button in the center of the steering wheel.

Combination light switch [3] (Indicator light

and light combination light switch)

The indicator light switch is on the right side of

the steering column and the switch is toggled

when turning.

Push forward-left turn indicator light;

N-neutral; Pull back-right turn indicator light.

The indicator light switch does not return to

the neutral position automatically and must be

reset manually.

To turn on the headlights and the front signal

light, turn this switch to align the position

marker on the switch handle with the

corresponding symbol on the switch body.

Ignition key switch [4]

O (off): The position to insert and pull out the

key; when the key is in this position, the engine

shuts down.

┃(On): When the start key is in “┃”, the circuit

is connected; after the engine is started, the

key remains in this position.

(Start): When the key is in the “ ”

position, the engine is started; after the engine

is started, the key automatically returns to the

“┃” position after release.

Diesel engine

When starting, the key is turned to the “┃”

position and the preheat indicator light [I]

turns on for a while; after the light turns off,

the key can be rotated to the “ ” position to

start the engine.

Caution

1. When the engine stops, do not leave the

key in the “┃” position to avoid battery

discharge.

2. When the engine is running, do not put the

key in the “ ” position to avoid motor

damage.

3. When starting, the starter motor cannot

continuously rotate for more than 10s and the

Turn left Turn right

14

interval between consecutive starts should be

120s.

Lifting lever [5]

This lever is used to lift or lower the forks.

Push forward - Down; Pull back - Up

The lifting speed is controlled by the backward

tilt angle of the lever and the accelerator pedal.

The lowering speed is only controlled by the

forward tilt angle of the lever.

Tilt lever [6]

This lever is used to tilt the mast forward and

backward.

Push forward - Forward tilt; Pull back -

Backward tilt

The tilt speed is determined by the tilt angle of

the lever and the throttle control.

Caution

The multiway valve is equipped with a

forward tilt self-locking valve. Therefore,

when the engine shuts down, the mast

cannot tilt forward even if the tilt lever is

pushed forward.

Side shift control lever (optional)

Accessory control lever (optional)

This lever is used to move the side shift frame

to the left or right.

Push forward – Move left; Pull back – Move

right

The side shift speed is determined by the tilt

angle of the lever and the throttle control.

Different types of accessories with different

functions are optional, thus the driver has to

be familiar with the operating method for each

accessory.

Cup holder [7]

A cup holder is set on the right side of the

instrument stand for the driver to place a cup.

Rocker switch [9] [optional configuration]

1. Alarm light switch: When pressing down, the

alarm light will flash; when pressing up, the

alarm light will turn off.

2. Rear headlight switch: When pressing down,

the rear headlight will turn on; when pressing

up, the rear headlight will turn off.

Rocker switch in a truck with a cab may be

different. Ventilation, demisting or other

Lift

Lower

Tilt forward

Tilt backward

Move to the left

Move to the right

15

functions are added.

Accelerator pedal [10]

When the accelerator pedal is pressed, the

engine speed and the truck speed will increase;

when the accelerator pedal is released the

engine speed and the truck speed will

decrease.

Brake pedal [11]

When the brake pedal is pressed the truck

slows down; when the brake pedal is pressed

to the bottom, the truck stops. When the pedal

is released the truck runs freely.

Caution

Avoid emergency braking. Emergency braking

can easily cause the truck to tilt or cargo to fall,

resulting in accidents.

Inching pedal [12]

When the pedal is pressed, the oil pressure of

the hydraulic clutch will drop. When the pedal

is pressed harder, the forklift truck will be

braked. The pedal can be used when the

forklift truck slows down to approach cargo or

conducts loading and unloading operations.

Caution

Do not use the inching pedal excessively. If the

pedal is used as a footrest or used for a long

time, it may cause overheating of the

automatic transmission oil or clutch slip.

Hand brake lever [13]

Pull the lever back to engage and push the

lever forward to release. Engage the lever

before the leaving the forklift truck.

Caution

In case of brake system failure or emergency,

the lever can be engaged for emergency

braking. Do not use the hand brake to slow

down during normal use.

Adjusting lever for steering wheel tilt angle [14]

The position of the steering wheel can be

adjusted. To perform adjustment, pull the

adjusting lever installed on the left side of the

steering hub column, move the steering wheel

to the desired position, and push down the

11

12

14

16

adjusting lever for locking.

Caution

a. Adjust the steering wheel tilt angle after

the forklift truck has stopped and the hand

brake is engaged.

b. Forcibly move the steering wheel up and

down to ensure that it has been locked after

adjusting.

Direction lever [15]

The direction lever is installed on the left side

of the steering hub column. This series of

forklift trucks adopt electrical steering and the

functions realized by moving the lever forward

and backward are as follows:

1.5~X5.5t

F

Forward

N

Neutral

R

Reverse

4.0~x5.5t

F

Forward

N

Neutral

R

Reverse

Press the brake pedal to the bottom to fully

stop the truck before changing the driving

direction; push the lever forward to engage

forward gear I; pull up and push the lever

forward to engage forward gear II from gear I.

Press the brake pedal to slow down if it is

required to reverse; pull back the lever to

engage reverse gear I; pull up and push the

lever back to engage reverse gear II from

reverse gear I.

Caution

The engine can only be started when the

lever is in the neutral position.

Emergency power-off switch [17]

Press down the emergency power-off switch to

disconnect the electric appliances from the

battery.

If the forklift truck needs to be restarted, the

emergency power-off switch should be

toggled.

Close the emergency power-off switch 30s

after shutdown.

17

3. Body and other parts

Load-backrest

The load-backrest ensures the stable loading of

cargos. The forklift truck must not be operated

without a load-backrest.

Driver's seat

1. Driver's seat weight adjusting handle

2. Forward and backward adjusting handle for

the driver's seat

3. Backrest angle adjusting handle

4. Handrail adjusting knob

· Driver's seat weight adjustment

According to the user’s weight, the weight

adjusting lever can be lifted up and moved

horizontally until the user gets comfortable.

· Forward and backward adjustment of the

driver's seat

Pull the adjustment handle inward by hand,

then push the whole seat forward and

backward to reach the desired position, the

handle is automatically locked when lowered

· Backrest angle adjusting

While sitting on the driver's seat, lean back on

the backrest, pull the backrest angle adjusting

lever upward with your left hand, lean forward

or backward, and release the lever until the

backrest angle reaches the desired position.

·Handrail adjusting

The handrail tilt angle can be adjusted by

rotating the adjusting knob. When rotating the

knob outward, the front end of the handrail

will lift. When rotating the knob inward, the

front end of the handrail will lower.

Warning

⚫The ignition key switch must be

turned off before adjusting the driver's

seat.

⚫The seat position can be adjusted

when the forklift truck has stopped.

⚫Do not adjust the driver's seat

when driving to avoid an accident.

⚫For front and rear adjustment and

backrest angle adjustment, the handle

should be pulled in place to ensure that

the structure is completely disengaged

before adjustment.

⚫After adjustment, the levers should

return to the locked position. Ensure that

all the components are locked securely

before using the forklift truck.

Safety belt

·Fasten the safety belt

An auxiliary action is required before pulling

out the safety belt which may require some

familiarization.

One type of seat: You need to press the white

round button (with the text "press to release")

with one hand, and then the seat belt can be

pulled out with the other hand. Then, the belt

can be inserted into the socket on the other

side of the driver's seat.

You may also encounter another kind of

driver's seat: The driver's seat with a rotating

safety belt box. When the safety belt box is

rotated forward, the safety belt cannot be

pulled out; when the box is rotated backward,

the safety belt can be pulled out and inserted

into the socket on the other side of the driver's

seat; the safety belt box must be rotated

forward again to return to the normal working

position.

Your back and waist should be as close to the

driver's seat as possible when fastening the

safety belt. Do not fasten the safety belt at the

abdomen.

Do not tilt the backrest too much; otherwise,

the safety belt will not be extended correctly.

Do not knot or twist the belt.

1

2

3

4

Other manuals for XF Series

1

This manual suits for next models

10

Table of contents

Other HANGCHA Forklift manuals

HANGCHA

HANGCHA J Series User manual

HANGCHA

HANGCHA R Series User manual

HANGCHA

HANGCHA CPCD30/35-XW43E-RT Quick start guide

HANGCHA

HANGCHA XC Series User manual

HANGCHA

HANGCHA XE Series User manual

HANGCHA

HANGCHA CPD10-A User manual

HANGCHA

HANGCHA CBD20-AMC1 Installation guide

HANGCHA

HANGCHA XF Series Quick start guide

HANGCHA

HANGCHA CBD15-A2MC1 User manual