Chapter1Introduction

Thismanualisforuserinstallationanddebuggingandroutine

maintenance.

1.Maketheopen-packageinspection.

Pleasecheck:ifproductappearanceisdamagedordeformation;

whetherthecomponentsaredamagedordrop;checkthe

nameplateratingonthecasetoseeifitisyourorder;check

whetherthetimeslistedinthepackinglistarecomplete;please

contactthesupplierimmediatelyiftherearequestionsor

damages.

2.Pleasereadthismanualcarefullybeforeuseandkeepit

properly.

3.Serviceenvironments

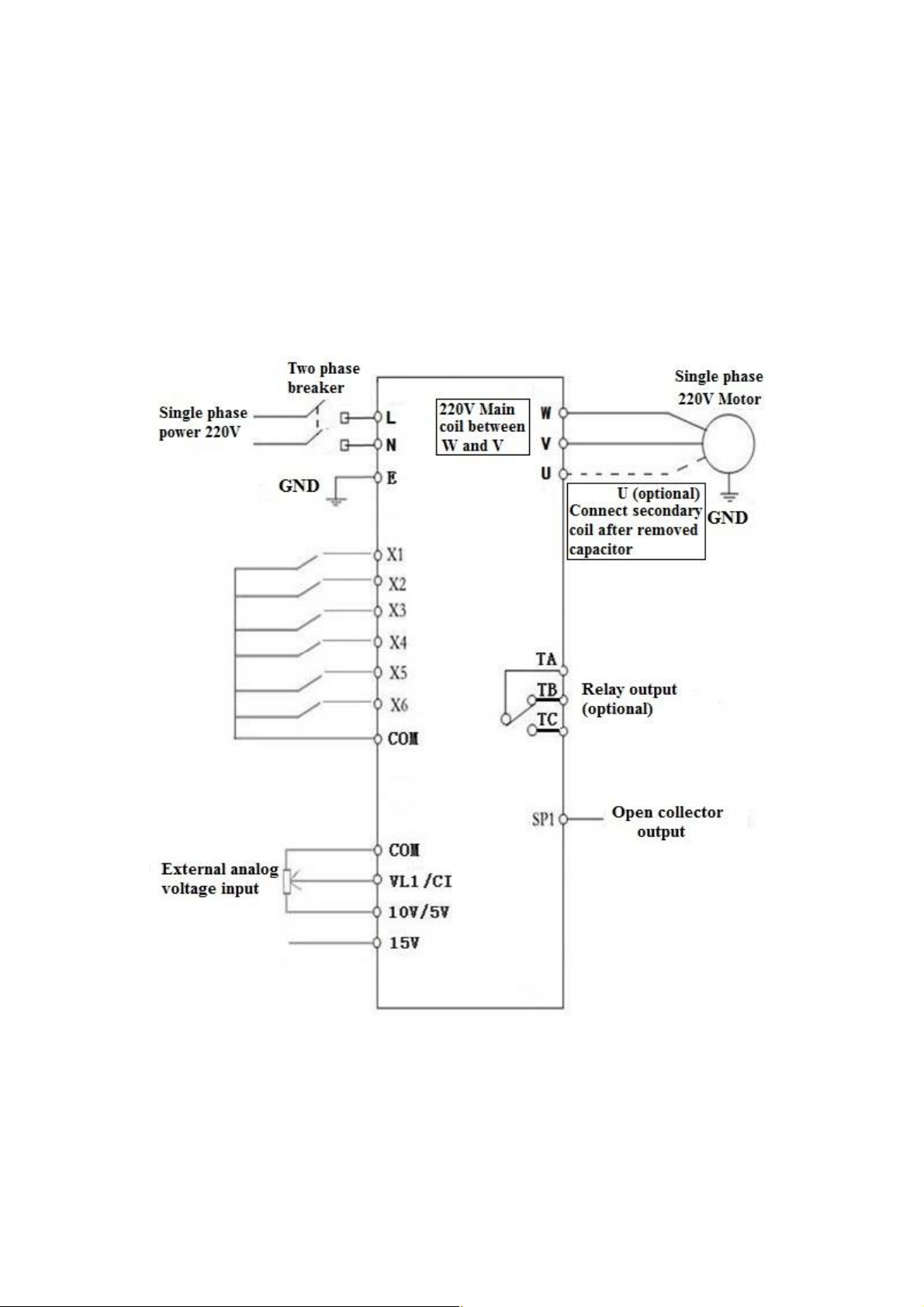

PowerSupply

1页

Three-phaseinputAC380V+20%(forAT3)

Temperature:-10℃~50℃

Humidity :0%~65%

4.Mattersneedattention

Turnoffthepowersupplywhenconnecting.

MakesurethattheACpowerisnotconnectedtothemotor

output.

5.Usethescenewithoutdew,dust,noncorrosiveliquid/gas.

6.Installationpartsstrong,novibration.

7.Duetothesmallsize,pleasemakesurethewireisconnected

well

8.Ifinhightemperatureenvironment,pleasesetenoughheat

dissipationspace.