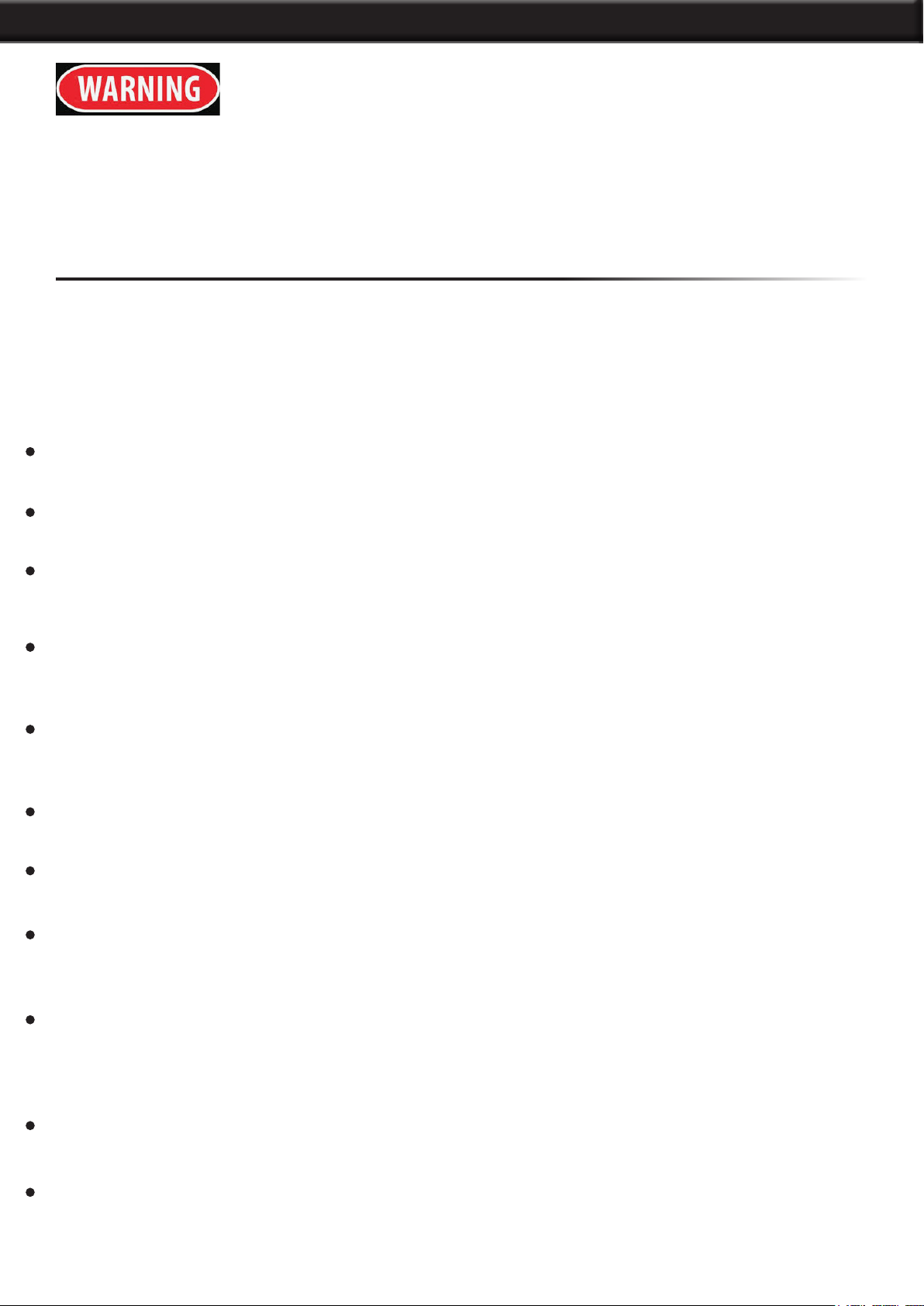

ASSEMBLY

The machine is equipped with two handles and a blade guard. The motor has overload and overheat

protection. It has an integrated water feed system as required for diamond cutting and has a portable

residual current device (PRCD) for electrical safety. It is used primarily with diamond blades, but abrasive

wheels may also be used with this machine. It is intended for cutting masonry, stone, concrete, reinforced

concrete and similar materials. All other uses are prohibited.

DESCRIPTION

ADJUSTING THE DEPTH OF CUT

Loosen the wing bolt on the depth guide and move the base up or down. At the desired depth of cut, secure

the base by tightening the wing bolt. In the case that you adjust the cutting depth to the maximum one,

ALWAYS be sure to do the adjustment after adjustment of the wheel gaurd.

SECURING THE WHEEL GUARD

CAUTION: The wheel guard must be adjusted on the tool so that the closed side of the guard always points

toward the operator. The wheel guard can be adjusted about 80 degrees, after you loosen the clamping nut.

Adjust to the desired angle, then secure the clamping nut.

SWITCH ACTION

CAUTION: Before plugging in the tool, ALWAYS check to see that the switch trigger actuates properly and

returns to the OFF position when released.

CAUTION: Switch can be locked in ON position for ease of operator comfort during extended use. Apply

caution when locking the tool in the ON position and maintain a rm grasp on the tool. To start the tool,

simply pull the switch trigger. Release the switch trigger to stop. For continuous operation, pull the switch

trigger, push in the lock lever and then release the switch trigger. To stop the tool from the locked position,

pull the switch trigger fully, then release it.

DO NOT pull the switch trigger hard without pressing the lock lever. This can cause switch breakage. To

prevent the switch trigger from accidentally being pulled, a lock lever is provided. To start the tool, push in

the lock lever and then pull the switch trigger. Release the switch trigger to stop.

There is a removable brush at the rear of the guard to help contain sparks, dust, debris and slurry. To install

simply push the brush into the slot in the bottom of the dust port bracket until it clicks into place. This brush

may be pulled straight out to replace when worn.

BLADE GUARD BRUSH

the spring-loaded splash guard is useful to help contain slurry which splashes toward the back. To install,

simply clip into place on the back of the dust port bracket. To remove, tilt upward to pop free. If the splash

guard is not needed, such as when cutting dry, it may be clipped up out of the way. Simply engage the male

clip on the ap with the female clip on the mount. Unclip to release.

SPLASH GUARD

Water is a basic requirement for diamond sawing with wet-type diamond blades. The water serves as a

coolant to avoid the working surface of the diamond segments from overheating. When the diamond bit

becomes overheated, both the bond matrix and even the diamonds break down, thus destroying the blade.

Beside cooling, water also keeps down dust and ushes away abrasive particles.

WATER CONNECTION

WARNING: ALWAYS use the GFCI when operating with water. NEVER allow water to enter the motor. It

can lead to electric shock.

WARNING: The maximum water pressure should not exceed 70PSI (4bar).

3