This is the safety-alert symbol. When you see this symbol on your equipment or in this manual, look for one

of the following signal words and be alert to the potential for personal injury or death.

WARNING Warns about hazards that could cause serious personal injury or, death, and or major property

damage and if ignored presents a potential hazard.

CAUTION Warns about hazards that will or can cause minor or moderate personal injury and/or property

damage and if ignored presents a potential hazard. It can also make consumers aware of actions that are

unpredictable and unsafe.

The NOTICE label indicates special instructions that are important but not related to hazards.

READ, UNDERSTAND, AND FOLLOW ALL SAFETY AND OPERATION INSTRUCTIONS.

FAILURE TO FOLLOW SAFETY AND OPERATION INSTRUCTIONS CAN RESULT IN SEVERE

PERSONAL INJURY OR DEATH.

CAUTION To reduce risk of injury, do not permit children to use or climb on this product. Closely

supervise children at all times. The ANSI/NSPI-4 Standard (above-ground and on-ground pools)

their being used as a means of access to the pool by young children.

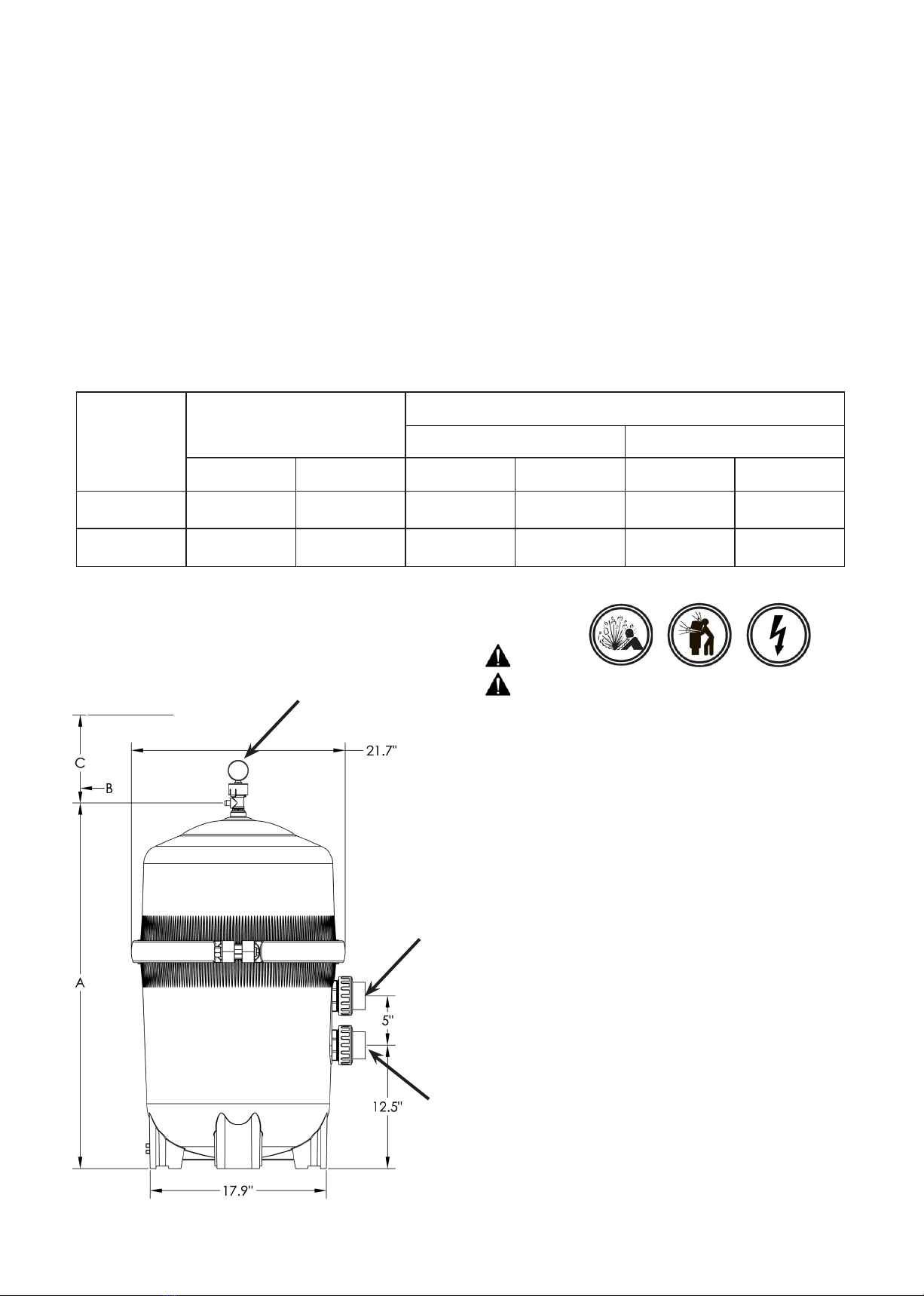

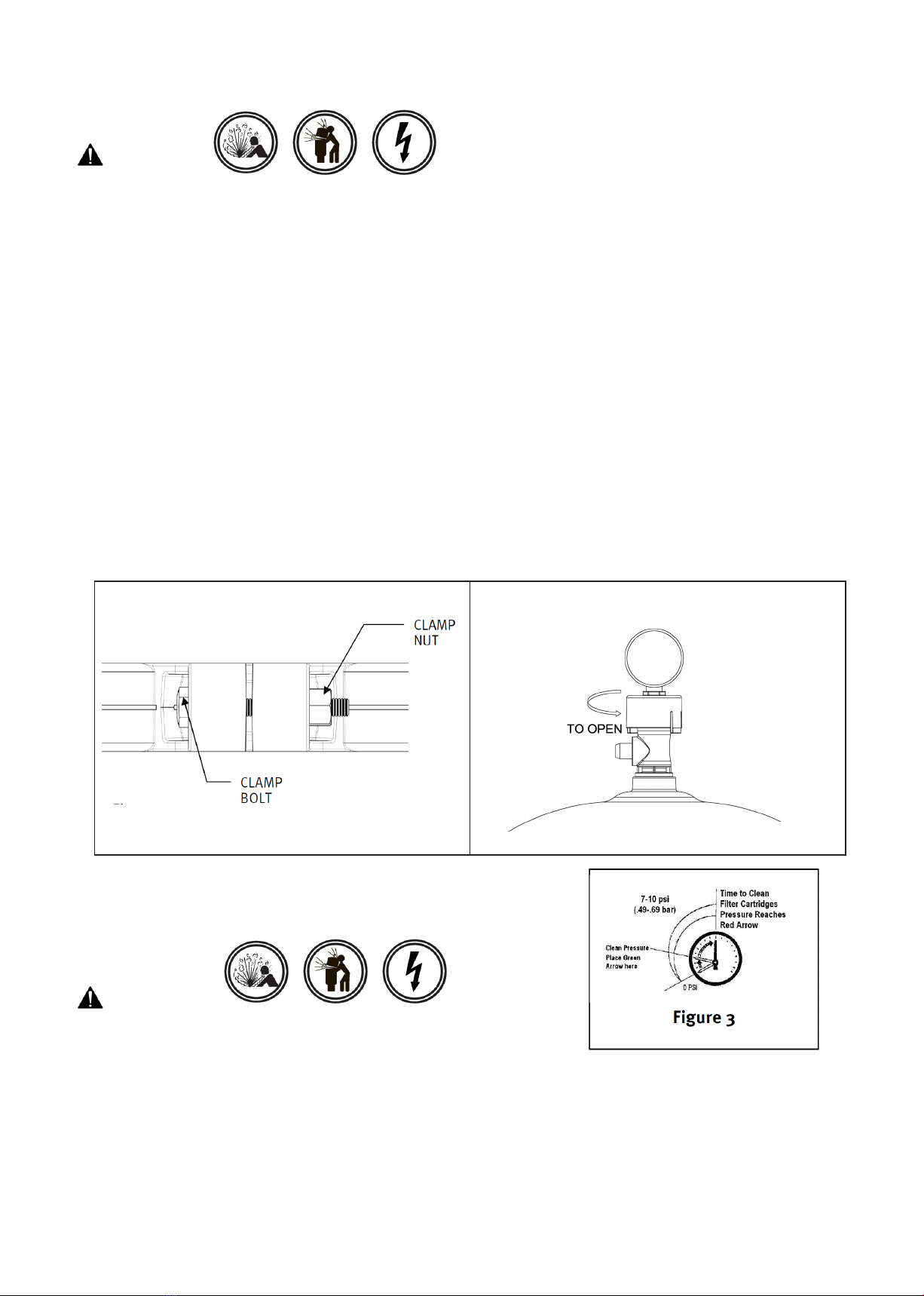

WARNING COMPONENT SEPARATION HAZARD

Pool and spa water circulation systems operate under hazardous pressure during start up, normal

operation, and possibly after pump shut off. Pressure in system can cause explosive component

injury or death can result.

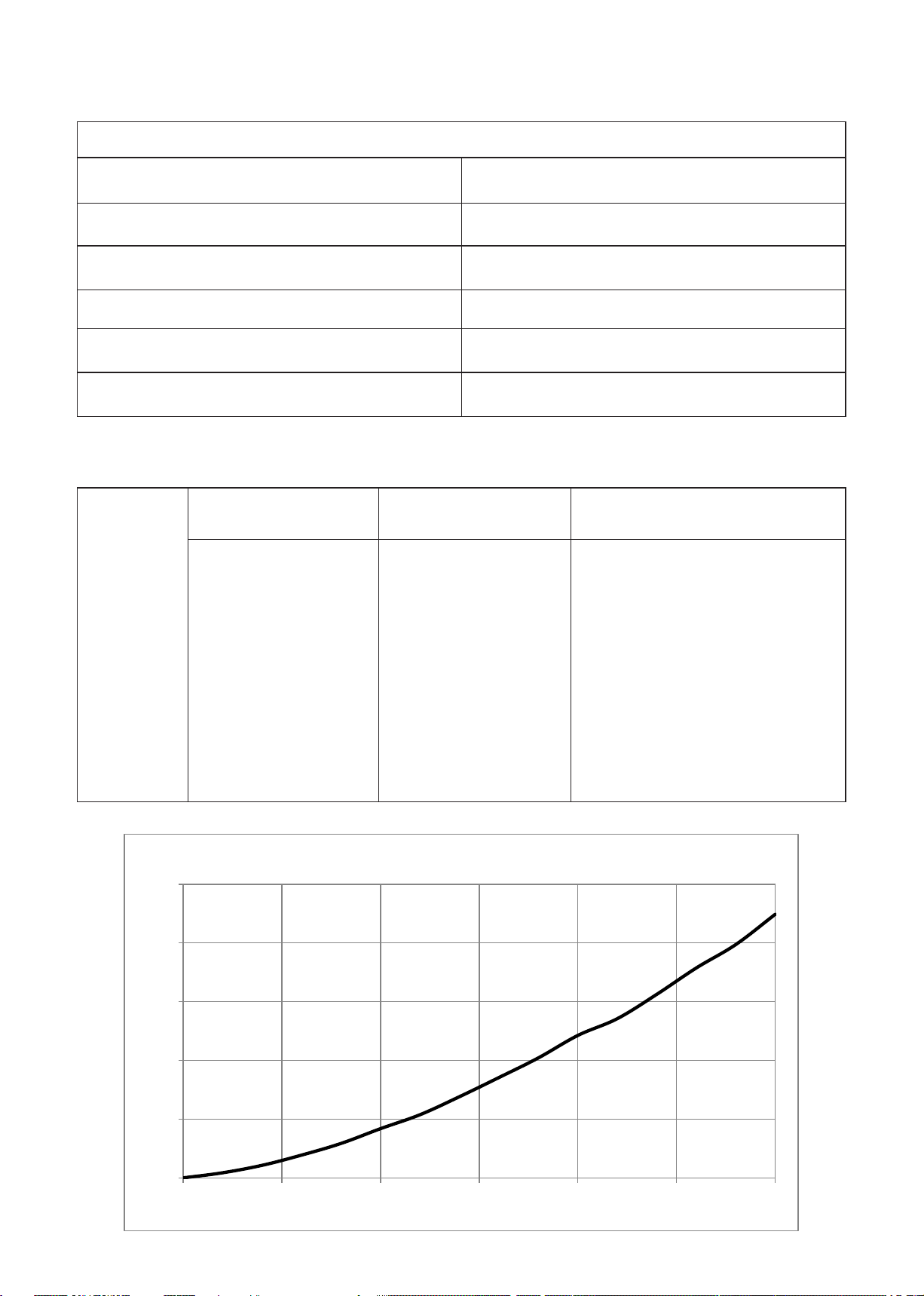

TO AVOID COMPONENT SEPARATION

missing, or not a genuine component.

cause explosive separation.

torque clamp nut and clamp bolt to 150 inch-lbs.

upper body.

the clamp system per the instructions in this owner’s manual to stop the leak.

water mix) is discharged from the manual air relief valve.

WARNING EXCESS PRESSURE HAZARD

of the components. Component separation can result in severe personal injury or death.