i143448 (D)

Table of Contents

CHAPTER 1 – INTRODUCTION ...................................................................................................................................1

PRODUCT OVERVIEW ....................................................................................................................................................1

STANDARD FEATURES ...................................................................................................................................................1

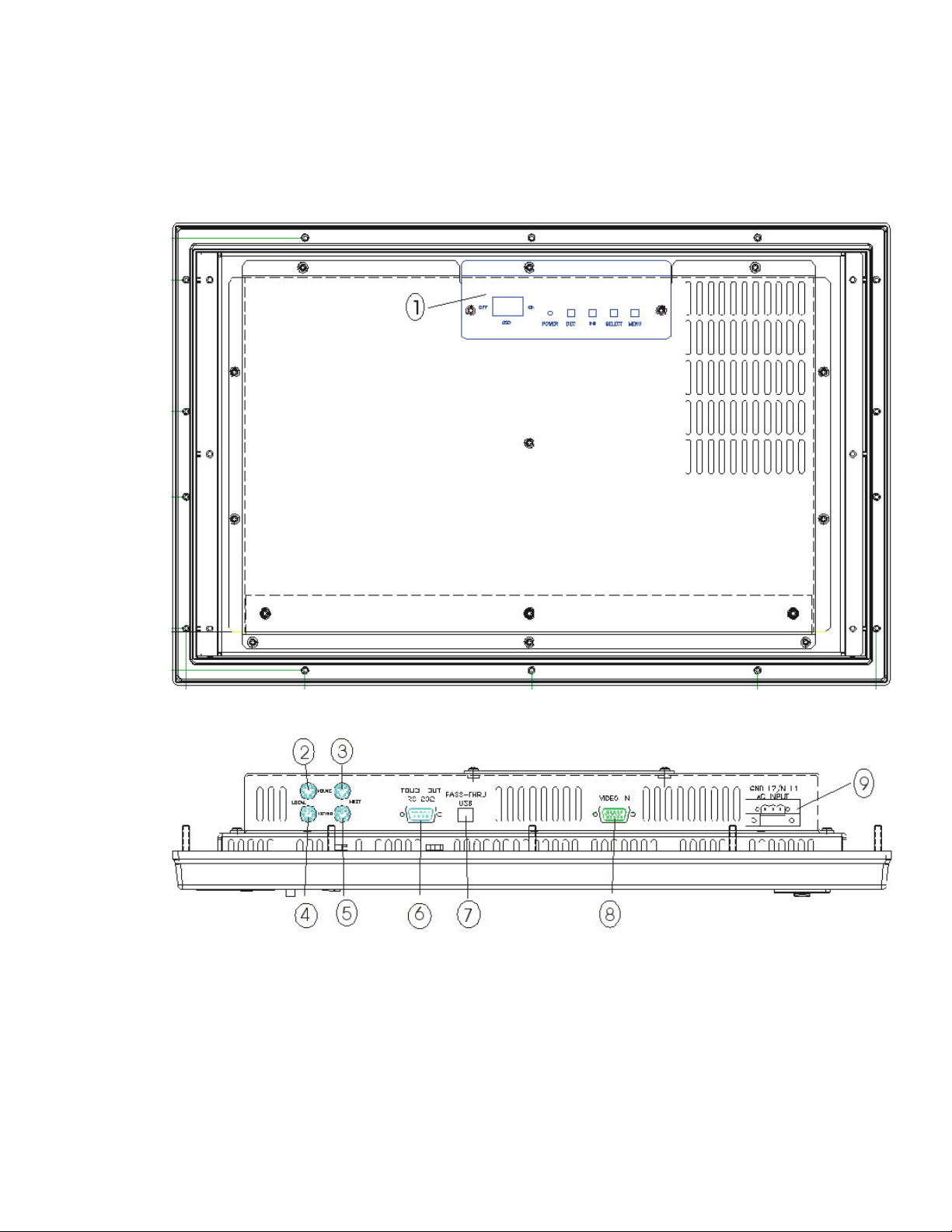

Front Panel Controls ..............................................................................................................................................2

Back Panel.............................................................................................................................................................5

UNPACKING THE UNIT....................................................................................................................................................7

QUICK STARTUP ...........................................................................................................................................................8

CHAPTER 2 – INSTALLATION.....................................................................................................................................9

INSTALLATION OVERVIEW...............................................................................................................................................9

SYSTEM CUTOUT DIMENSIONS .....................................................................................................................................11

5012KPM(T).........................................................................................................................................................11

5015KPM(T).........................................................................................................................................................12

POWER MANAGEMENT.................................................................................................................................................13

System Power......................................................................................................................................................13

Excessive Heat ....................................................................................................................................................14

Electrical Noise ....................................................................................................................................................14

Line Voltage Variation ..........................................................................................................................................15

General Compatibility Issues ...............................................................................................................................15

XVME COMPATIBILITY ISSUES .....................................................................................................................................16

USING A TOUCH SCREEN .............................................................................................................................................16

CUSTOM LOGO ...........................................................................................................................................................17

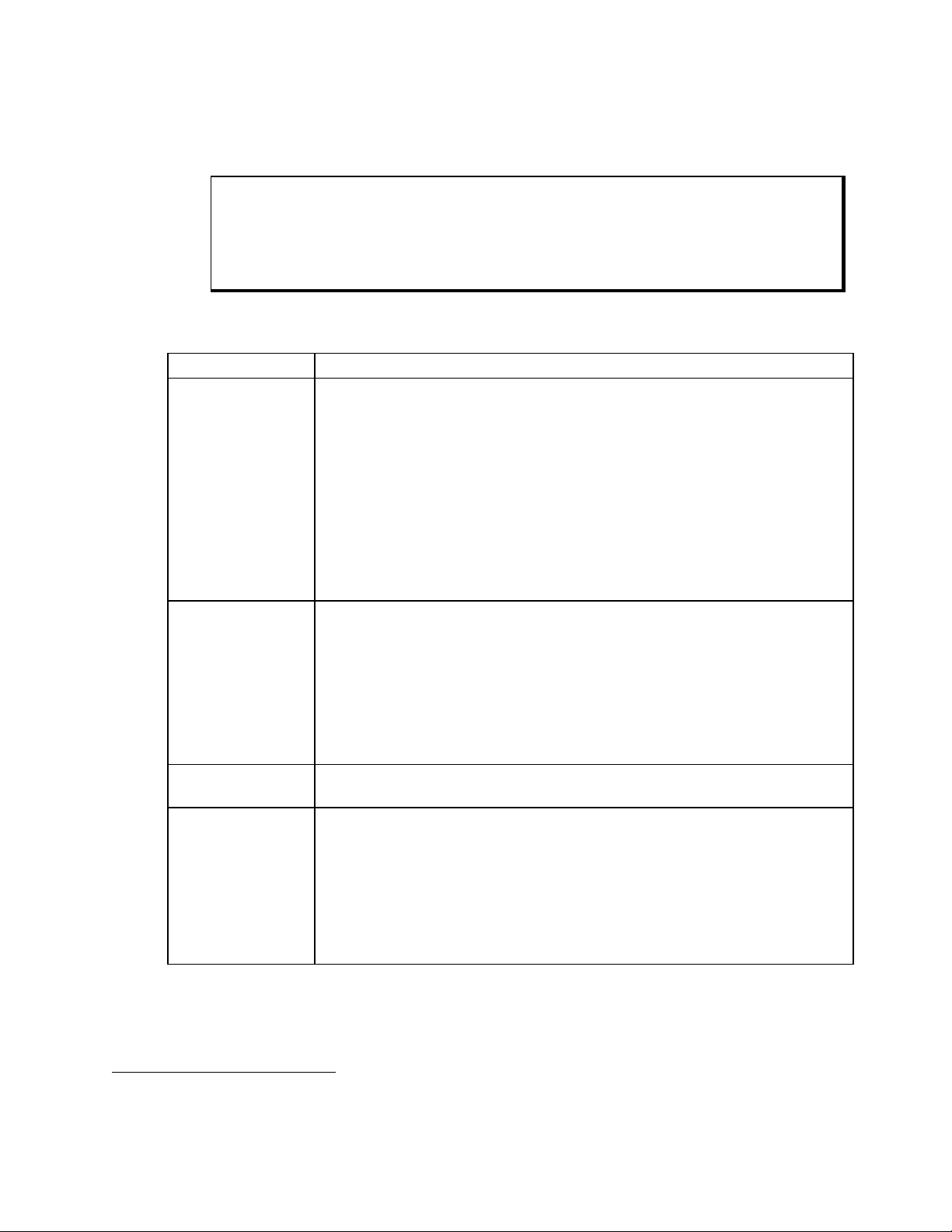

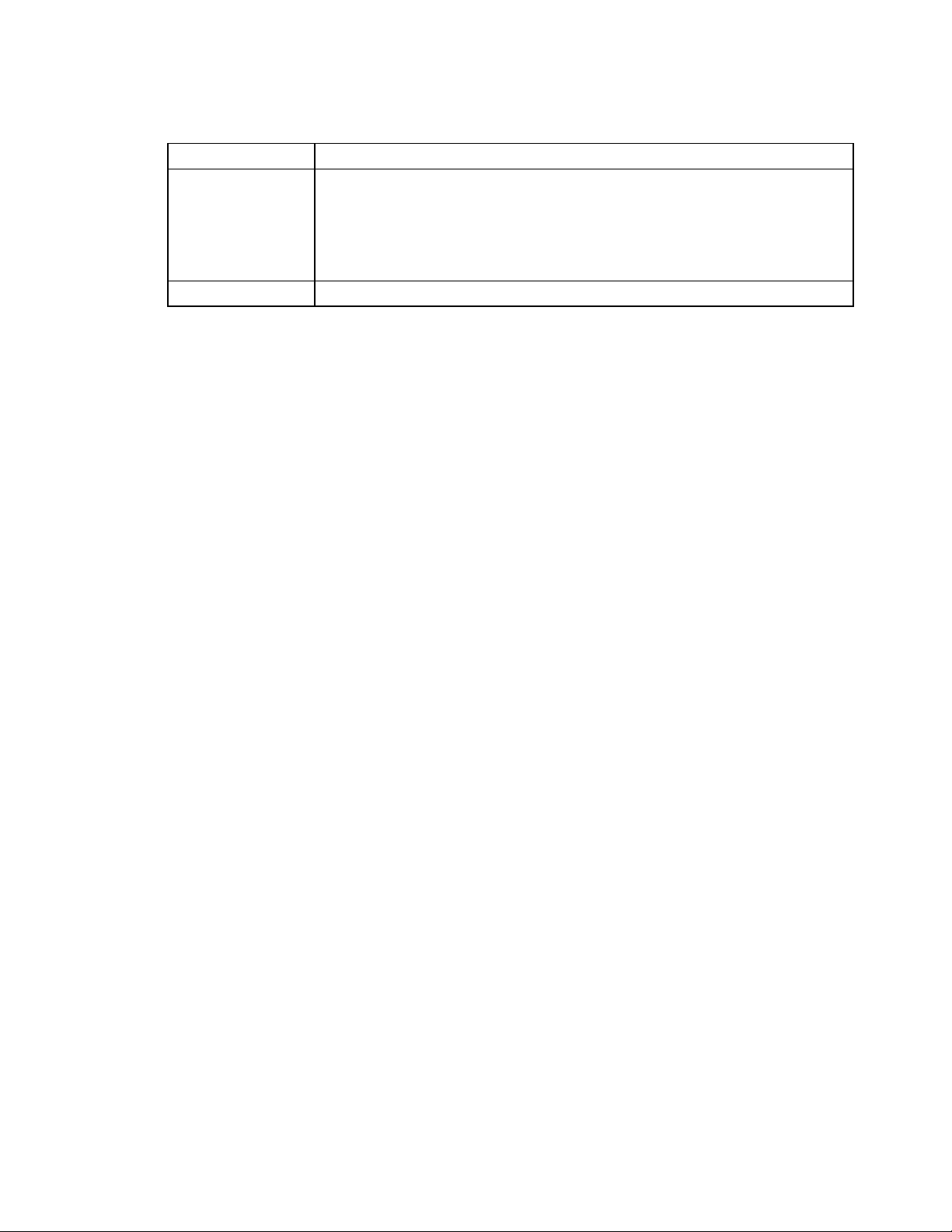

CREATING CUSTOM KEYPAD INSERTS ...........................................................................................................................17

HAZARDOUS LOCATIONS INSTALLATION .........................................................................................................................23

Safety Agency Approval.......................................................................................................................................24

Definitions ............................................................................................................................................................25

Class I Locations..................................................................................................................................................25

Class II Locations.................................................................................................................................................25

Division 1 Locations .............................................................................................................................................25

Division 2 Locations .............................................................................................................................................26

Groups .................................................................................................................................................................26

Enclosures ...........................................................................................................................................................27

Power Switch .......................................................................................................................................................27

Cable Connections...............................................................................................................................................28

Hazardous Locations Control Drawing.................................................................................................................29

Operation and Maintenance.................................................................................................................................30

CHAPTER 3 – MONITOR SETTINGS .........................................................................................................................31

ON SCREEN DISPLAY (OSD) SWITCH...........................................................................................................................31

MODE AND IMAGE ADJUSTMENT ...................................................................................................................................31

OSD Functions.....................................................................................................................................................32

Reset Factory Default Settings.............................................................................................................................34

ANALOG RGB INTERFACE SPECIFICATIONS ...................................................................................................................34

GRAPHIC MODES ........................................................................................................................................................35

CHAPTER 4 – OPERATOR INPUT.............................................................................................................................36

INSTALLING THE TOUCH SCREEN DRIVER ......................................................................................................................36

CALIBRATING THE TOUCH SCREEN................................................................................................................................37

USING A POINTING DEVICE WITH A TOUCH SCREEN FOR DOS.........................................................................................37

CHAPTER 5 – KEYPAD UTILITY PROGRAM............................................................................................................38

LOADING THE KEYPAD UTILITY .....................................................................................................................................38

USING THE KEYPAD UTILITY .........................................................................................................................................38

STARTUP....................................................................................................................................................................39

MAIN MENU................................................................................................................................................................39

Exit .......................................................................................................................................................................40

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com