Electronic Drive Manual

8

4.3.4 Special functions

4.3.4.1 Night mode

The Night Mode function cannot be used in cooling

systems.

Prerequisites:

• The circulator is installed in the supply line

• The “night condition” can be detected with good con-

dence if a higher-level control system is set to change

the supply temperature

When Night Mode is activated, by short pressing the

Control mode button (1) as described in sec. 4.3.3,

the indicator is permanently lit.

The Night Mode can be active in combination with each

one of the Control Modes described in sec. 4.3.3.

This function reduces the power consumption of the

circulator to the minimum when the heating system is

not running; an algorithm detects the proper working

conditions and automatically adjusts the speed of the

pump.

The pump returns to the original set point as soon as

the heating system restarts.

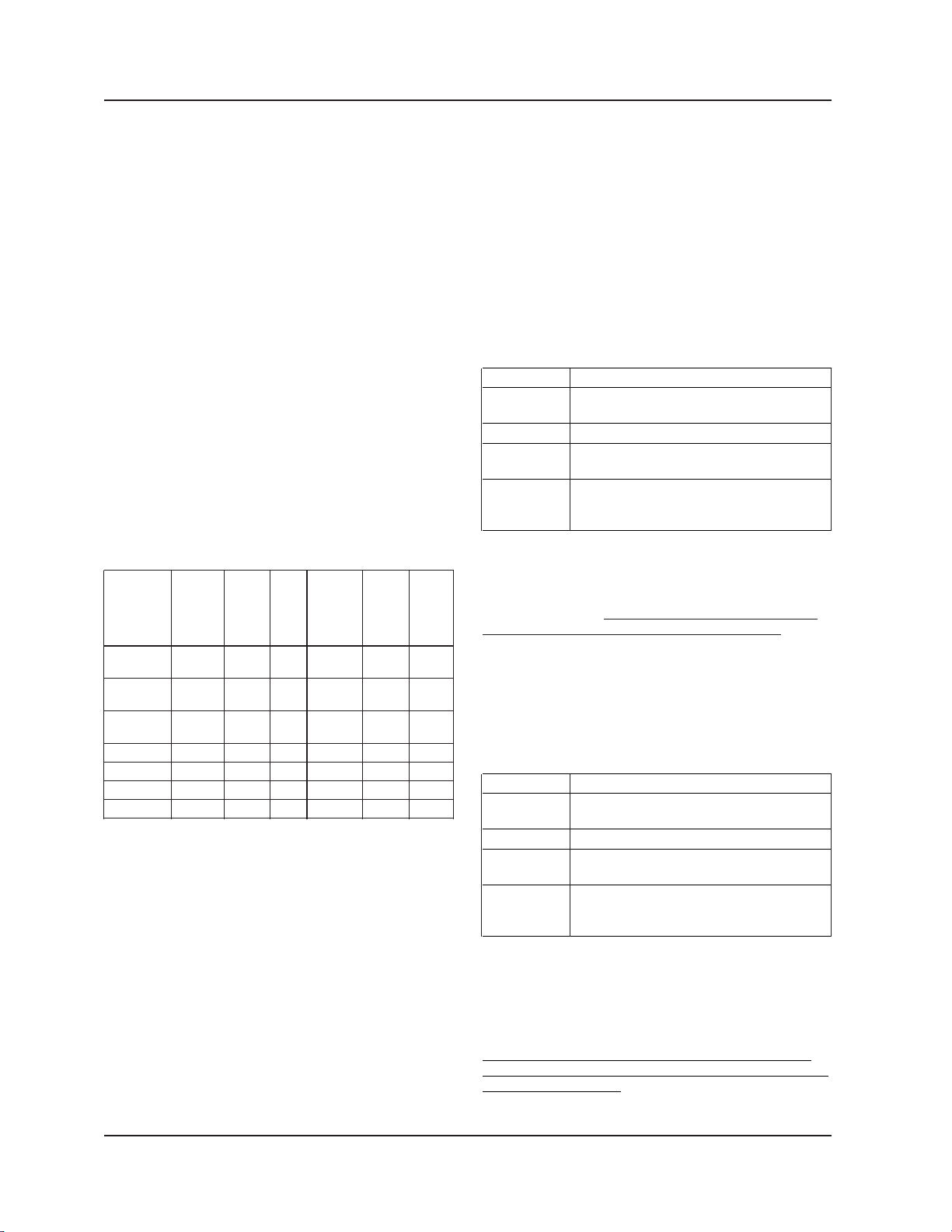

4.3.4.2 Air purge (Degassing)

At each power-on, the drive performs (factory default)

an automatic Air Purge procedure, with the aim of

ushing out air pockets from the circulator housing.

The Air Purge cycle will run the pump at a xed speed

for a predetermined length of time, followed by a shorter

period of minimum speed; this cycle will be repeated 4

times (in total approximately 60 seconds), with the mes-

sage 4DEG reporting the corresponding decrementing

counter (as described in sec. 3).

Referring to Figure 7, in the appendix:

• the Air Purge can be skipped or started up (at any

time) by short pressing (for about 2 seconds) both the

Setting buttons (5) (Up and Down arrow) together

• the Air Purge can be permanently enabled or disabled

(at any time) by long pressing (for at least 10seconds)

both the Setting buttons (5) (Up and Down arrow)

together: by this operation, in case of Air Purge initially

enabled (factory default), after 10 seconds the drive

will display the message dGOF. On the other hand, if

the Air Purge is initially disabled, then keeping the

button pressed for 10 seconds, will enable the Air

Purge and the drive will display the message dGOn.

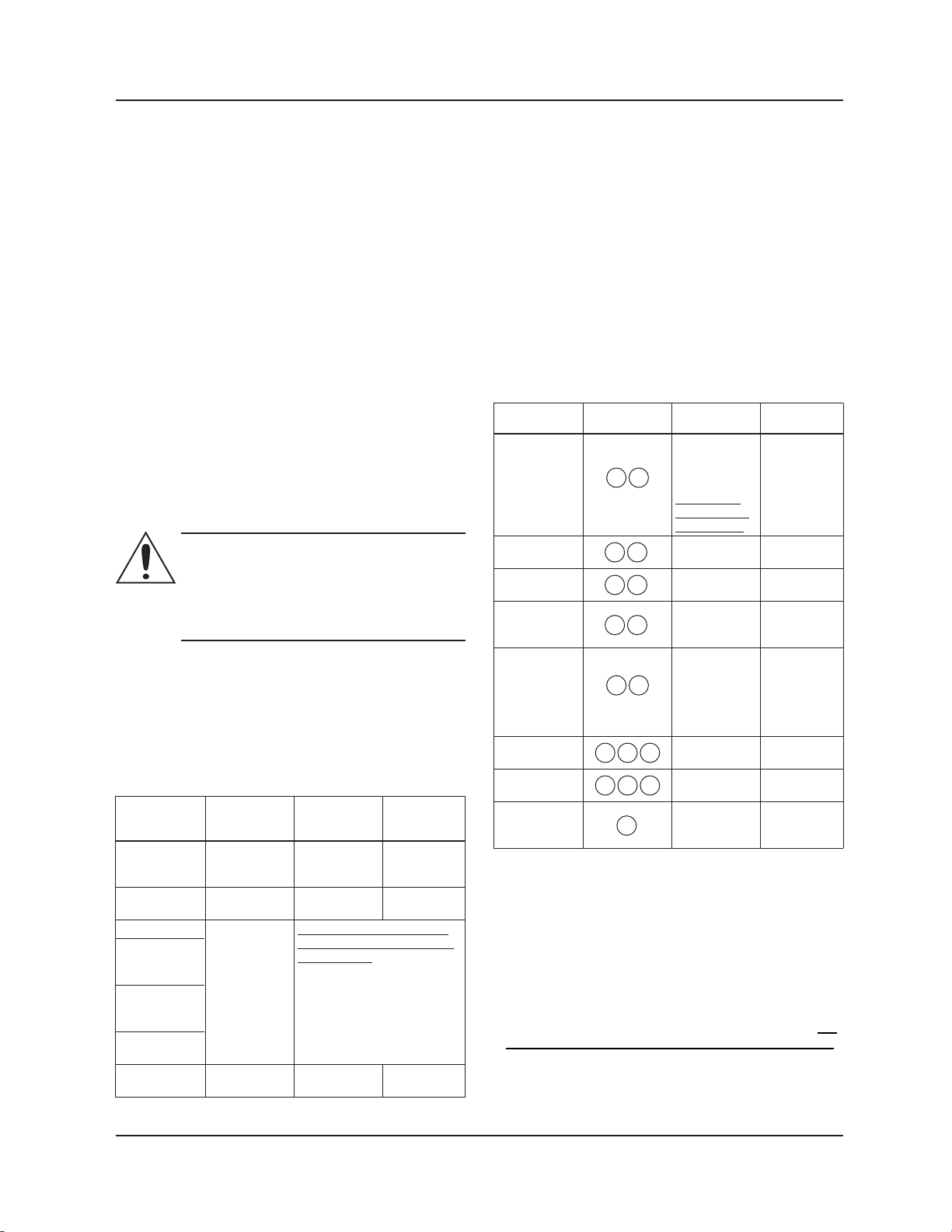

4.3.4.3 Keypad lock

Keypad Lock is a function with which the drive disables

all the buttons of the Control Panel, but maintains

running all the indicators and the numeric display.

The Control Panel can be locked/unlocked by pressing

simultaneously, and for two seconds, the Parameter

button (3) and the Up arrow button (5).

In any case, the drive will automatically lock the user

interface after 10 minutes from the last button pressure.

Once the lock is active, by pressing any button the drive

displays the symbol; unlocking the Control

Panel, the drive will display the symbol .

4.3.5 Sub-menus (parameters)

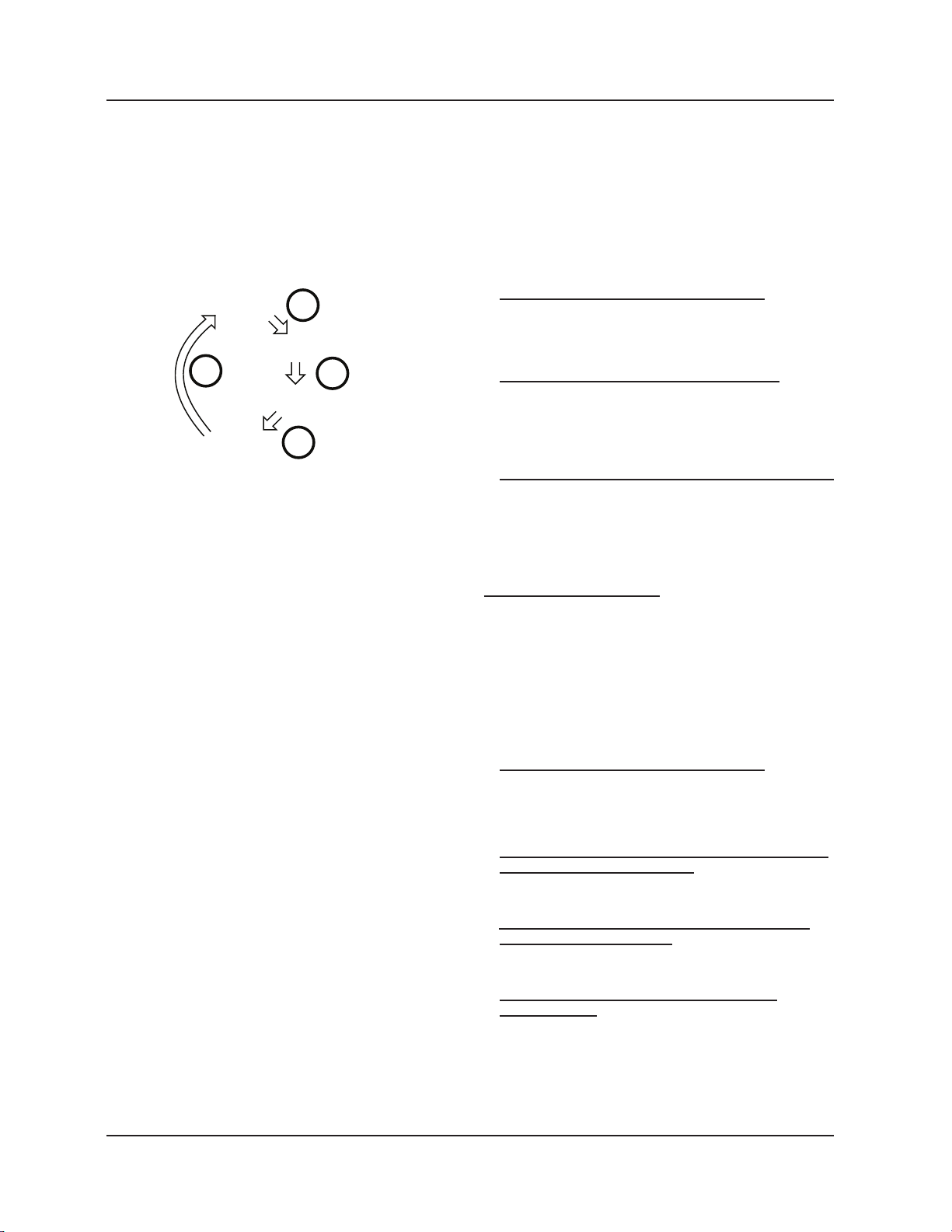

4.3.5.1 Dual pump operations settings

Each electronic drive can be congured to couple with

another drive, so that they start working in concert in

dual pump operation.

Prerequisites:

• Dual pump operation is available only when identical

pumps are used.

• Wire both pumps to terminals (15), (16) and (17) as

described in sec. 2.4 and sec. 2.5.6, connecting the

2x single-head pumps.

For a correct automatic conguration, follow the

subsequent procedure, by rst setting the pump

selected to be the master of the couple

1. Switch on the power supply to both the pumps

2. After few seconds, the drive will display the message

SING.

3. While this message (“SING”) is displayed, press

shortly one of the Setting buttons (5), in order to

congure the circulator as:

• Single Head Pump (factory default): the message

SING is ashing onto the Numeric Display (7).

• Dual Slave Pump: the message TUSL is ashing

onto the Numeric Display (7).

• Dual Master Pump: the message TUMA is ashing

onto the Numeric Display (6).

4. Press shortly the Parameter button (3) to conrm and

store the value selected.

The Numeric Display (7) stops ashing.

• When the Single Head Pump or Dual Slave Pump

conguration is nalized, the drive will proceed to the

next step as described in sec. 3, step 2.

• Only in case of Dual Master Pump, a new sub-

menu is made available (as described in the next

steps) for setting the dual pump operation

5. After few seconds, the drive will display the message

“BCUP”.

6. While this message (“BCUP”) is displayed, press

shortly one of the Setting buttons (5), in order to

congure the dual pump operation as:

Control Panel