Table of Contents

Introduction and Safety..................................................................................................................2

Introduction..................................................................................................................................2

Safety terminology and symbols............................................................................................... 2

User safety.................................................................................................................................... 3

Special hazards............................................................................................................................3

Protecting the environment....................................................................................................... 4

Spare parts................................................................................................................................... 5

Warranty....................................................................................................................................... 5

Transportation and Storage.......................................................................................................... 6

Inspect the delivery.....................................................................................................................6

Inspect the package................................................................................................................6

Inspect the unit........................................................................................................................ 6

Lifting............................................................................................................................................ 6

Product Description........................................................................................................................7

Jet aerator design....................................................................................................................... 7

Installation......................................................................................................................................10

Precautions.................................................................................................................................10

Requirements.............................................................................................................................10

Torque values............................................................................................................................ 11

Check before start-up...............................................................................................................11

Mechanical Installation................................................................................................................ 13

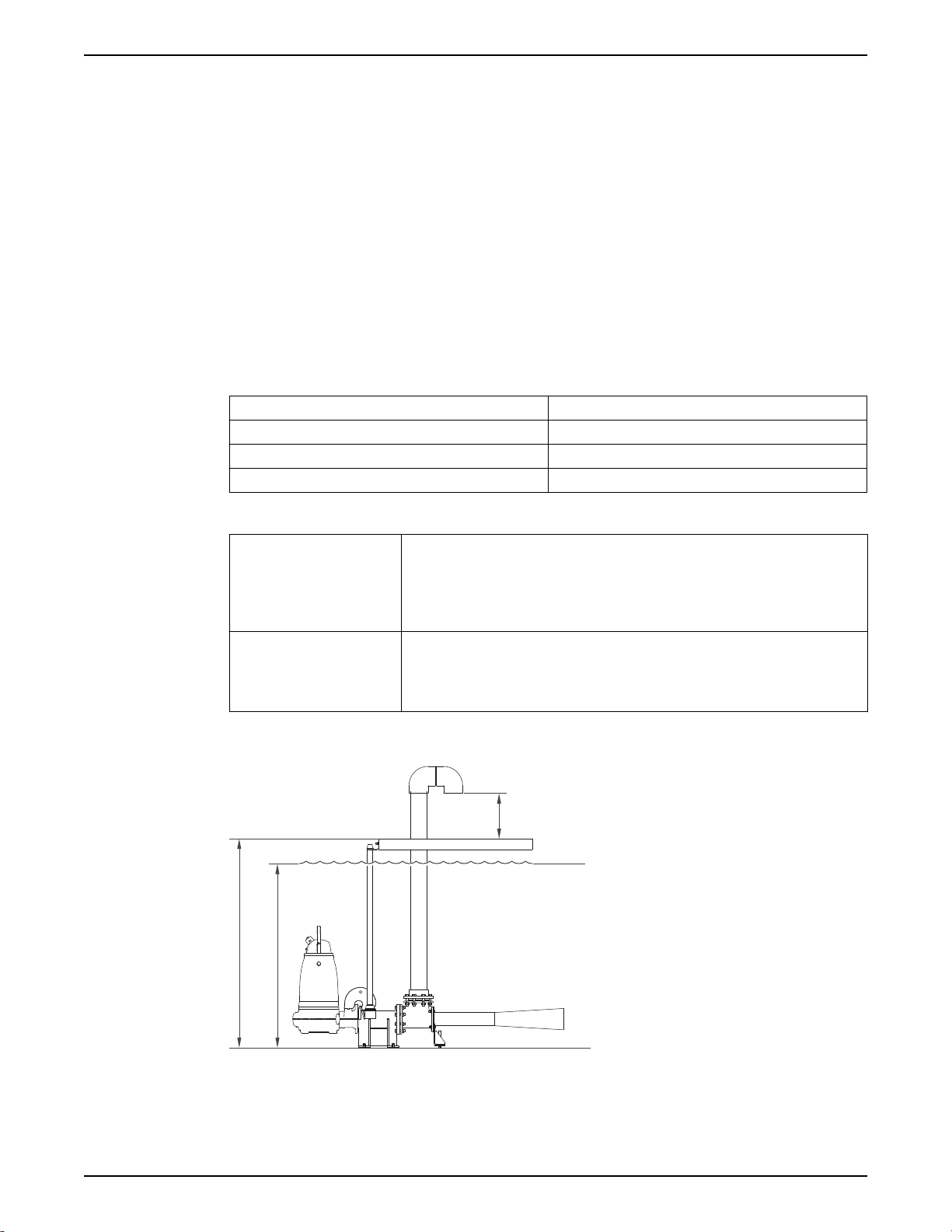

P-installation...............................................................................................................................13

JA 112 and JA 117, P-installation........................................................................................13

JA 217, P-installation.............................................................................................................15

JA 317, P-installation.............................................................................................................18

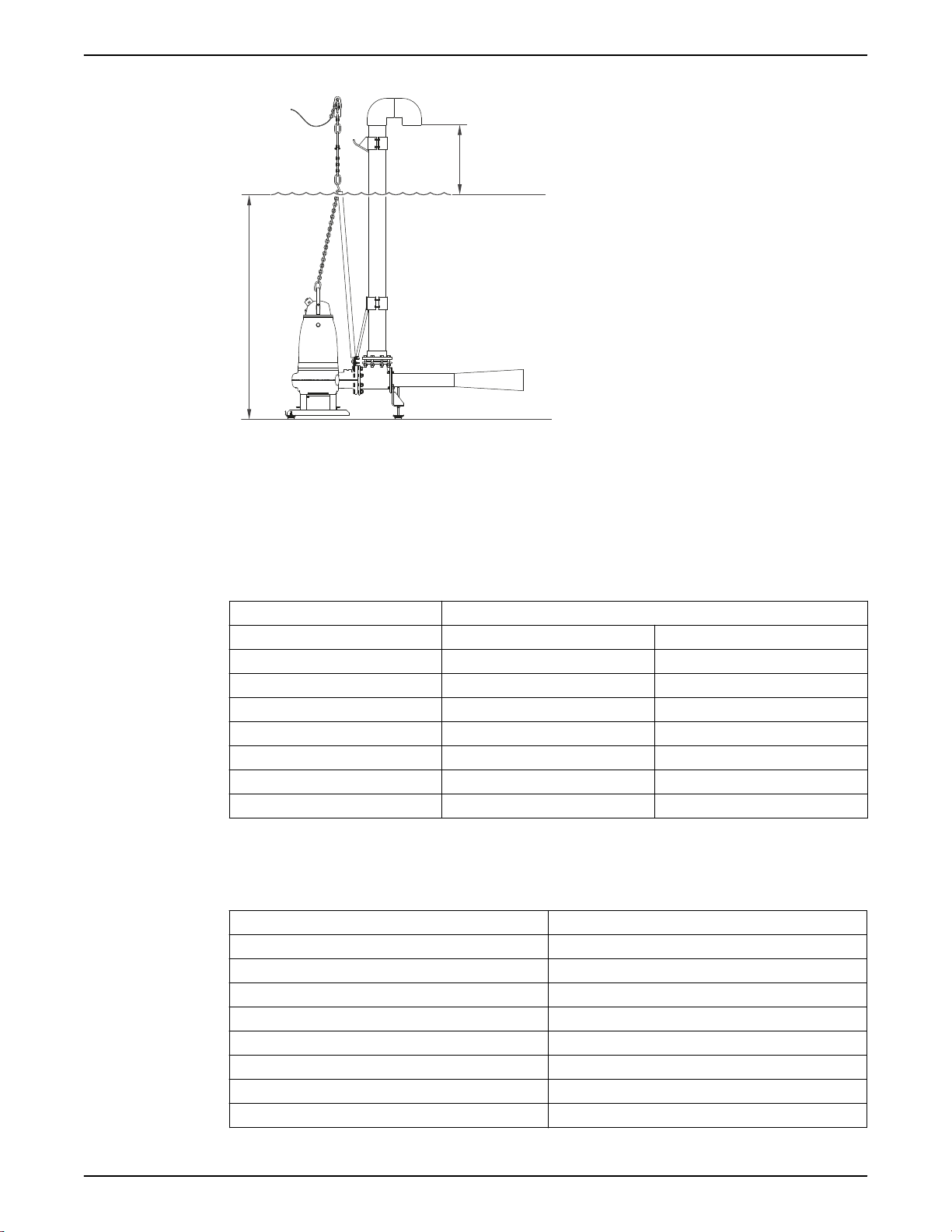

S-installation...............................................................................................................................21

JA 112, 3085, S-installation..................................................................................................21

JA 112, 3102, S-installation..................................................................................................24

JA 117, 3127, S-installation..................................................................................................27

JA 117, 3153 and 3171, S-installation................................................................................ 30

JA 217, S-installation.............................................................................................................33

JA 317, S-installation.............................................................................................................37

List of Parts.....................................................................................................................................42

P-installation, exploaded view.................................................................................................42

P-installation, parts list tables.................................................................................................. 42

S-installation, exploaded view.................................................................................................45

S-installation, parts list tables...................................................................................................45

Table of Contents

Flygt jet aerator JA 112, JA 117, JA 217, JA 317 Installation, Operation, and Maintenance Manual 1