Parts list (model 3000)

Disassembly specific to 2000 lip seal model:

To avoid inducing leaks, remove the lip seal from the body only if

being replaced. To remove the seal from the body seal bore, remove

the pump body from the motor by loosening and removing the 2 off

M5 screws using an 8mm (5/16”) spanner. With the body removed,

manually press the lip seal out the front of the body seal bore.

Alternatively the lip seal can be removed from the front of the body

using a small screwdriver to pries out the seal from the seal bore.

Ensure not the scratch the seal bore with the screwdriver as this will

create a leak path for the fluid to escape the pump. With the body

removed, the slinger can be accessed and removed. This

component deters any leaking fluid from entering the motor; a small

but important part of the pump. Replace it if perished or it no longer

grips the shaft. Clean the body and slinger before re-assembly.

Component cleaning should be done with soap and water. Do not

clean elastomers with solvents.

Disassembly specific to 3000 mechanical seal model:

To avoid inducing leaks, remove the mechanical seal from the pump

only if being replaced. To remove the seal from the pump, remove

the pump body from the motor by loosening and removing the 2 off

M5 screws using an 8mm (5/16”) spanner. On removal, the static

face of the seal (white ceramic) will be left in the body, the dynamic

face of the seal (metal encased carbon) will be on the shaft. Press

the static face out the back of the body, taking care not to scratch

the seal bore. The O ring on the dynamic metal case circumference

is the slinger. Remove the slinger. Slide off the dynamic seal face.

Whilst inspecting the mechanical seal faces, take care not to touch,

scratch or otherwise damage the shiny lapped seal surfaces. If the

seal leaks, look for radial grooves, large chips or scratches

traversing in the carbon seal face. Also look for effective grip of the

elastomer on the shaft. If no fault can be found, the leak may not be

from the mechanical seal. Finally remove the plastic Support

washer. The support washer optimizes the mechanical seal function

and is an important part of the design.

Reassemble the pump in the reverse order to the disassembly.

Specific to 2000 lip seal model

Position the slinger to within 4mm (3/16”) of the motor end cover.

Press the lip seal (“closed” face first) into the pump body seal bore.

Ensure it is fully seated. Lubricating with soapy water may help

seating. Do not use grease.

Specific to 3000 mechanical seal model:

Place the support washer over the motor shaft and rest against the

motor bearing. Place the O ring slinger centrally over the dynamic

seal face metal casing and slide that over the motor shaft to sit

against the support washer. Push the static seal face fully into the

body seal bore. The above two actions will be eased using soapy

water as a lubricant. Do not use grease. Ensure the seal faces are

clean and free of debris, grit and other contaminants which will

cause the seal to leak.

Secure the pump body to the motor by fitting and tightening the 2 off

M5 screws using an 8mm (5/16”) spanner. Tighten to 3.7-4.2Nm

(2.7-3.1 ftlb). Secure the Cam to the body with cam screw and O

ring. Tighten to 3.7-4.2 Nm (2.7-3.1ftlb). Do not over tighten as this

will potentially cause leaks due to over compression of the O ring.

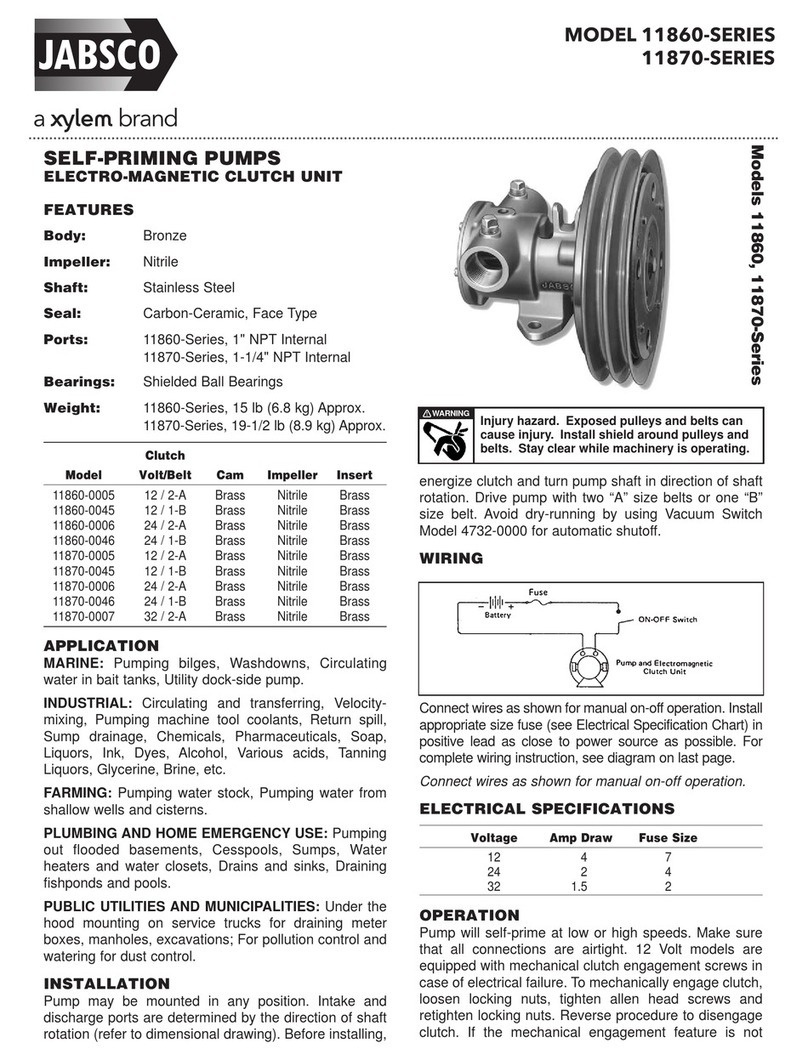

The impeller hub single flat mates with the shaft single flat. Lubricate

the impeller and body impeller bore with Jabsco impeller lubricant

43000-0802 (lubricant and end cover O ring included in impeller kit

6303 & 7273-0003-P). Insert the impeller using a clockwise twisting

movement. Place the end cover O ring into the body O ring groove.

Smearing the O ring with lubricant helps keep it in place whilst the

end cover is fitted. Secure the end cover to the body with the 4 off

end cover M5 screws using an 8mm (5/16”) spanner. Tighten to 3.7-

4.2 Nm (2.7-3.1ftlb). Re-install to the system secure electrical and

physical connections and follow the “initial startup procedure”

detailed above

8. CUSTOMER SUPPORT

If any pump units for any reason need to be returned,

please ensure the pump unit has been fully drained before

returning. Please contact customer services for more

information

9. ENVIRONMENTAL PROTECTION

Due consideration to environmental issues have

been made within the design and manufacturing

process of this product without compromising

product performance and value.

WEEE Policy

The Waste Electrical and Electronic Equipment

Directive (WEEE Directive) is a European

Community Directive 2012/19/EU on waste

electrical and electronic equipment which

became European Law in February 2003. The

WEEE Directive set collection, recycling and recovery targets for all

types of electrical goods.

Xylem Water Services Limited has identified that their product range

comes under Category 6 (Electrical tools) and as such will undertake

their responsibilities in line with the above directive and will fulfill

their legal obligation by means of joining a compliance scheme.

All products are identified by means of the Wheelie bin logo as laid

down in the above directive.

The Xylem Water Services Limited WEEE producer registration

number is WEEE/RM07081

Full details of scheme can be found @ Valpak Limited

Unit 4, Montague House, Stratford-upon-Avon Business and

Technology Park, Banbury Road, Stratford-upon-Avon,

At the end of your product and accessories life, it must not be

discarded as domestic waste.

Please contact your distributor / supplier for further information.

For end users outside of the EU consult applicable regulations.

This product should only be dismantled for recycling by an

authorized recycling company.

*Mechanical Seal (static)

Mechanical Seal (Dynamic)