8G-800DXA / -1000DXA / -2800DXA User Manual

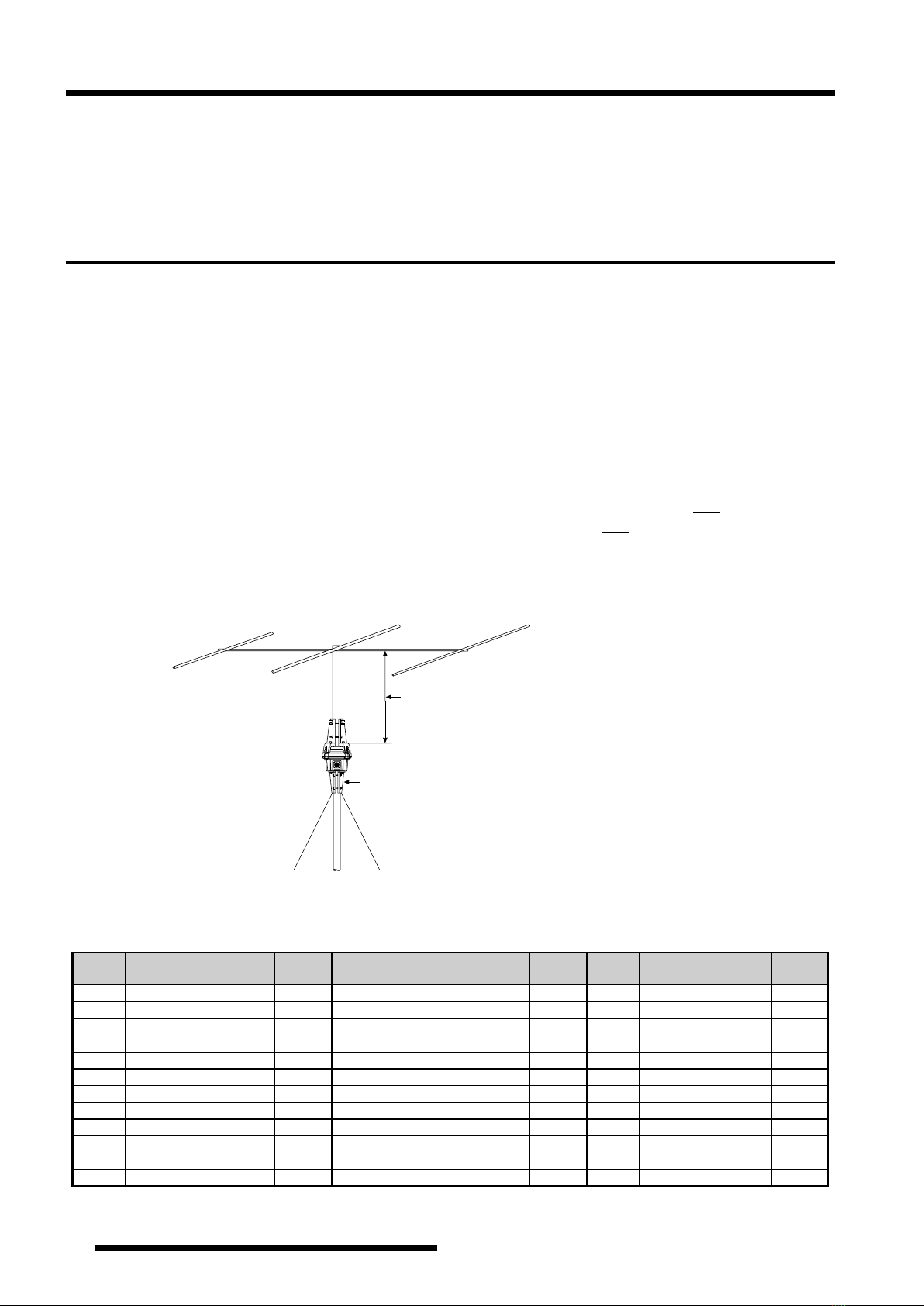

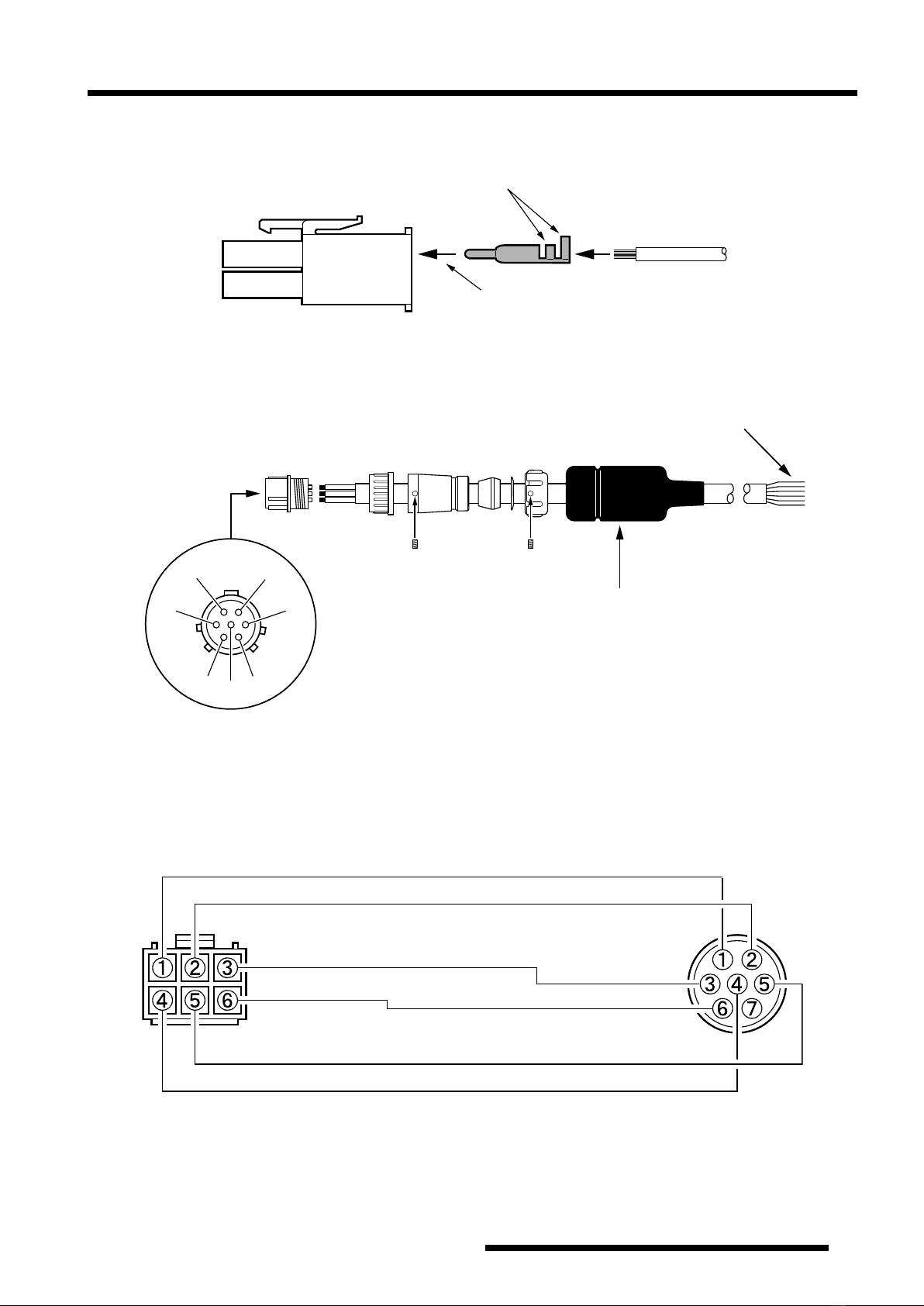

Mounting the Rotator and Antenna

INDOOR PERFORMANCE CHECK AND ALIGNMENT

1. Temporarily connect the control cable between the

rotator unit and the controller.

2. Turn the SPEED control fully counter-clockwise,

and set the SELECT SWITCH on the rear panel to

the right (ADJ. MODE) position.

3. Check to be sure that the POWER switch on the con-

troller is set to “OFF”, then plug the controller’s AC

cable into your station’s AC outlet.

4. Set the controller’s POWER switch to “ON”. Verify

that the controller’s pilot lights have become illumi-

nated.

5. Press the LEFT (rotation) side of the seesaw switch,

and continue to hold it until the rotator reaches the

counter-clockwise position where it automatically

stops (“Left” represents counter-clockwise rotation

when the rotator is viewed from the top).

6. When the rotator has reached the left “stop” posi-

tion, release the LEFT switch, and check to see if the

controller’s indicator needle is pointing to 180° (S:

South).

If the indicator needle is out of alignment, grasp the

edge of the bezel around the bearing window, turn it

10° counter-clockwise, and pull it off. Then, grasp the

needle at its center and pull it straight off, replace the

needle to 180° (straight down), and replace the bezel.

7. Just above the round connector jack on the rotator

unit, you will observe two raised calibration marks

(one each on the “rotating” bell and “fixed” base

of the rotator). These two marks should be directly

aligned with each other. If not, place a small piece of

masking tape on the rotating bell and the xed base of

the rotator unit, and make a calibration mark will be

used to verify the amount of rotation in the next step.

8. Press the RIGHT (rotation) side of the seesaw switch,

and continue rotating to the right until the calibration

marks (from step 7) are again precisely aligned. Now

check the indicator needle, which should also have

rotated fully 360° so as to be pointing exactly to 180°.

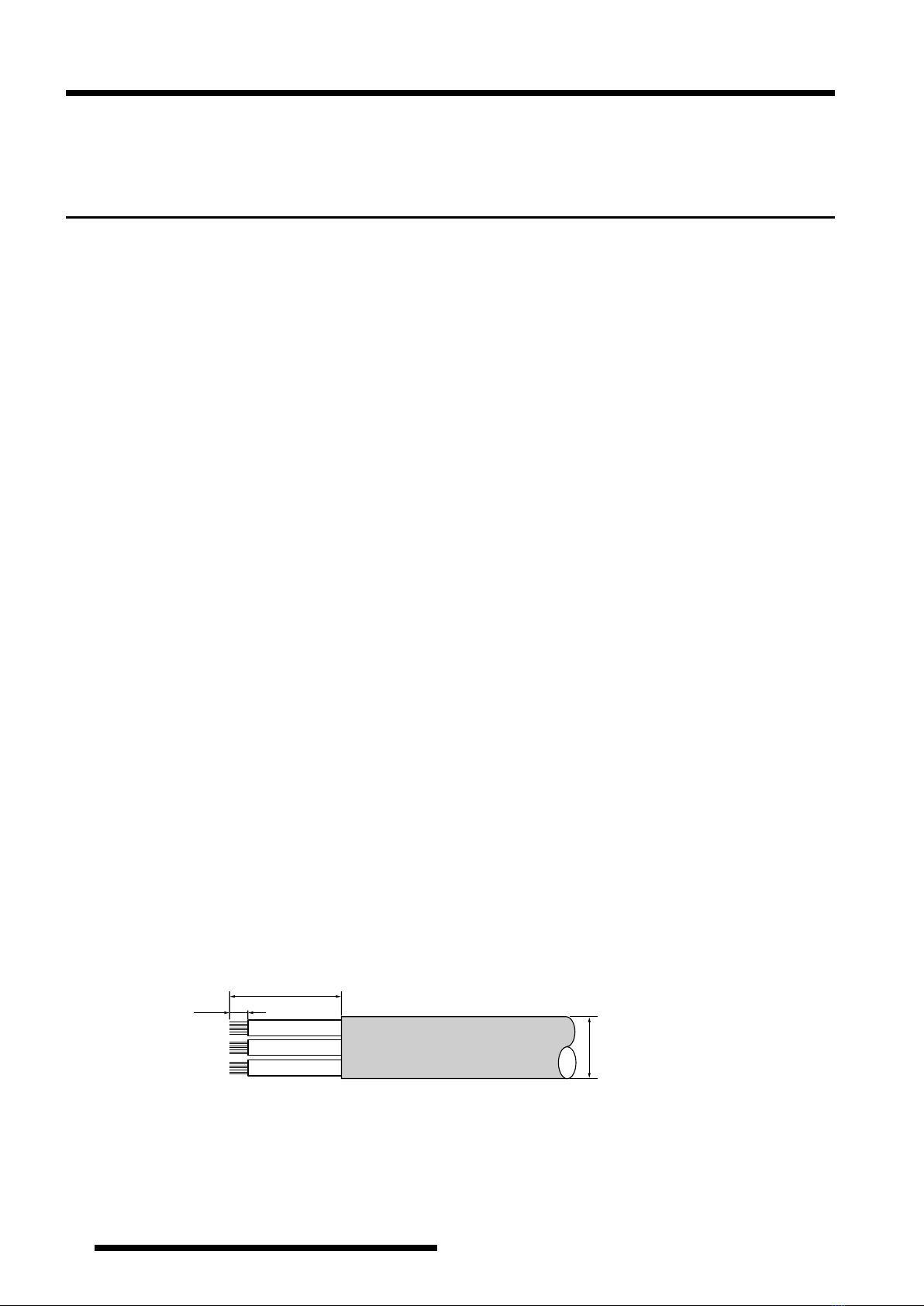

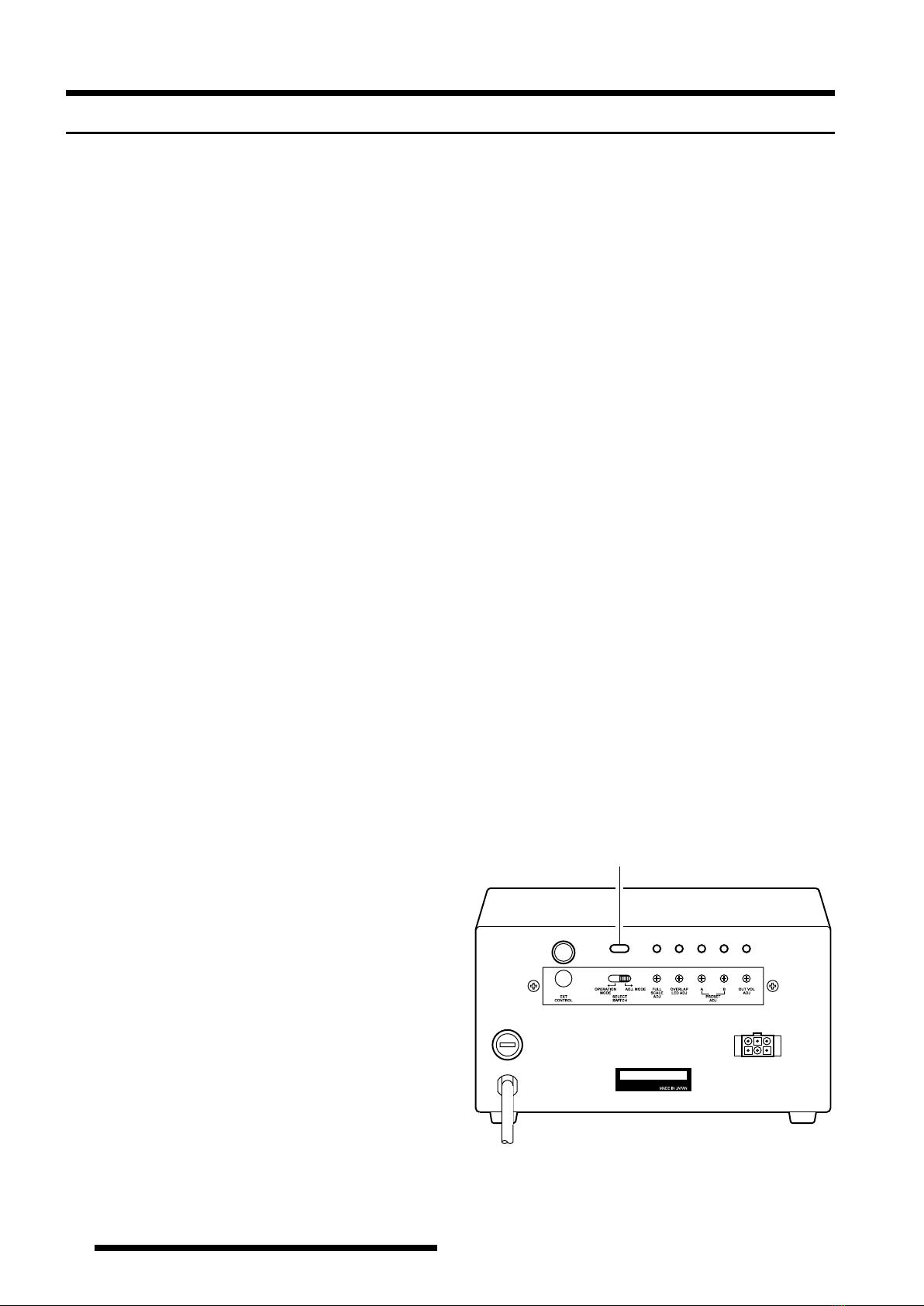

If the indicator needle is not pointing exactly to 180°,

go to the rear panel of the controller, and use a small

screwdriver to adjust the FULL SCALE ADJ po-

tentiometer (see the drawing to the right) so that the

indicator needle points exactly to 180°.

9. Press the RIGHT switch again, and continue rotation

to the right. You should observe the OVERLAP LED

becoming illuminated as rotation passes the 180°

point.

If the OVERLAP LED does not light up at the 180°

position, the OVERLAP LED ADJ potentiometer (on

the rear panel of the controller) may be used to align

the illumination threshold to the 180° point.

10. Check to verify that rotation automatically stops at

approximately 270° (West; representing a total rota-

tion range of 450° from the original starting point).

11. Press the LEFT and RIGHT (rotation) switches a

few more times, verifying that rotation appears to be

normal. If so, press the LEFT or RIGHT (rotation)

switch to set the rotator to 270° (West).

12. Set the PRESET control to 180° (fully counter-

clockwise), and press the START switch. The rotator

should rotate counter-clockwise, and stop exactly at

180°.

If not, go to the rear panel of the controller, and use

a small screwdriver to adjust the PRESET ADJ A

potentiometer so that the rotator stops at exactly 180°.

13. Set the PRESET control to 270° (fully clockwise),

and press the PRESET switch. The rotator should ro-

tate clockwise, and stop at exactly 450° (270°; West).

If not, go to the rear panel of the controller, use a

small screwdriver to adjust the PRESET ADJ B po-

tentiometer so that the rotator stops at exactly 450°.

14. Repeat steps 12 and 13 several times until the indica-

tor responds reliably to presetting small angles when

the rotator is near both ends of its range.

15. Set the SELECT SWITCH on the rear panel to the

left (OPERATION MODE) position, and turn the

POWER switch “OFF”.

16. This completes the ground-based testing of the rotator

and controller.

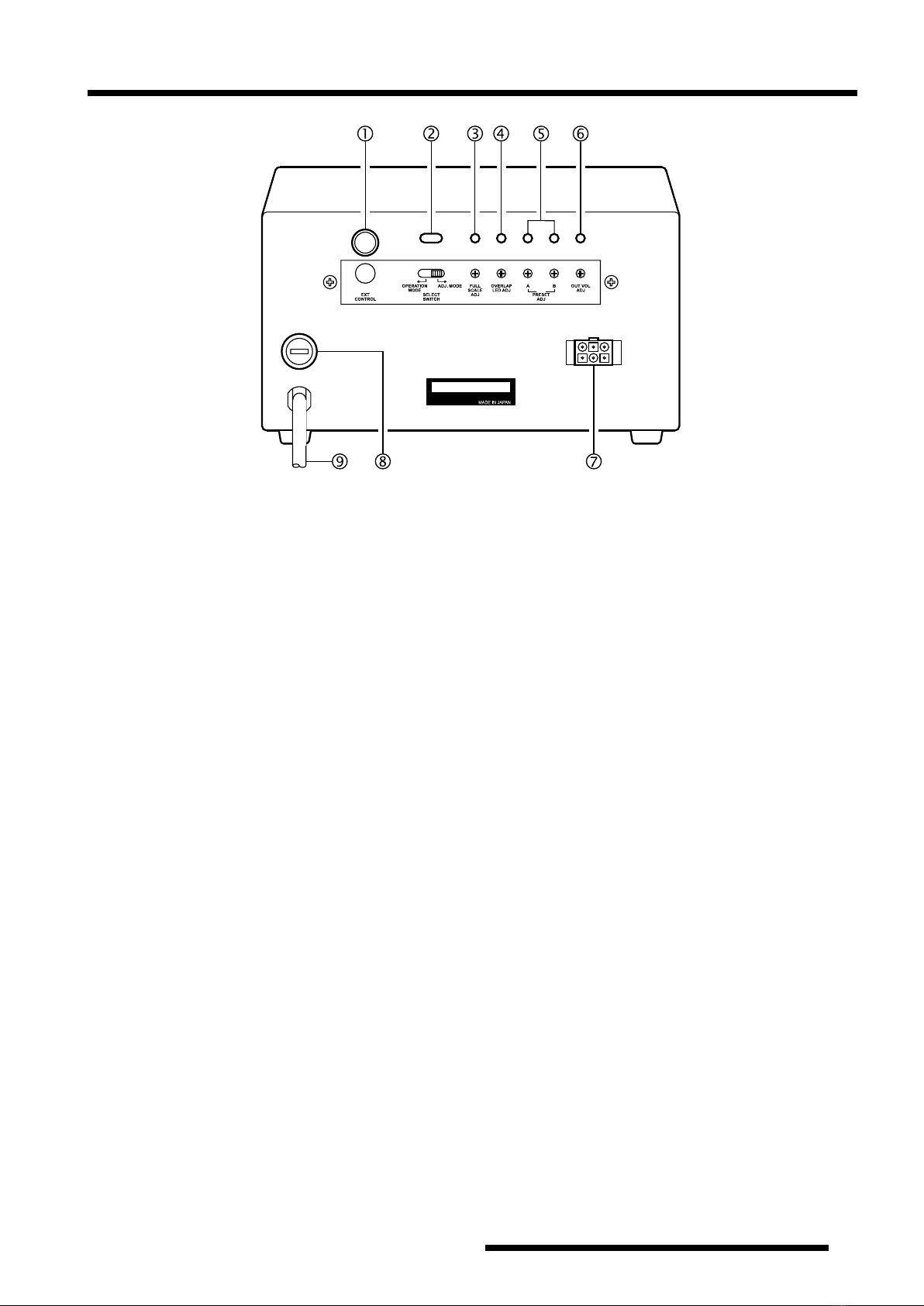

Controller Rear Panel

YAESU MUSEN CO., LTD.

SELECT SWITCH