1

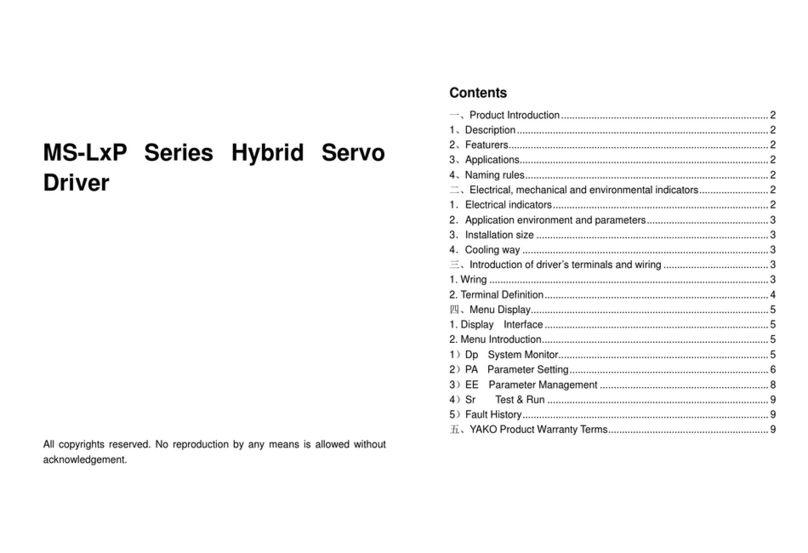

Content

Content ............................................................................................................................................. 1

Chapter 1: Selection of Servo System .............................................................................................. 2

1.1 Drive specifications ............................................................................................................ 2

1.2 Servo motors and drives model description ........................................................................ 3

1.3 Servo driver and servo motor matching .............................................................................. 4

1.4 Matching motor number ..................................................................................................... 5

1.5 Auxiliary cable ................................................................................................................... 5

1.6 Braking resistance specication ............................................................................................ 6

Chapter 2: Product Installation and Dimensions .............................................................................. 7

2.1 Servo drive dimensions ....................................................................................................... 7

2.2 Servo drive installation ....................................................................................................... 7

Chapter 3: Servo Drive and Motor Connection ................................................................................ 8

3.1 System structure diagram ................................................................................................... 8

3.2 Main circuit......................................................................................................................... 9

3.2.1 Introduction of each part .......................................................................................... 9

3.3 Encoder interface ................................................................................................................ 9

3.4 Control signal ................................................................................................................... 11

3.4.1 Digital input and output signal ............................................................................... 14

3.4.2 Position command input signal .............................................................................. 17

3.5 Communication signals .................................................................................................... 19

Mini USB communication CN5 ..................................................................................... 19

Chapter 4: Operation and Adjustment ............................................................................................ 20

4.1 Panel operator description ................................................................................................ 20

4.1.1 Interface introduction ............................................................................................. 20

4.1.2 Parameter setting and display ................................................................................ 21

4.1.3 Monitorable parameter list ..................................................................................... 22

4.2 Operating mode instructions ............................................................................................. 23

4.2.1 Position mode ........................................................................................................ 23

Chapter 5: Auxiliary Functions ...................................................................................................... 27

5.1 JOG run ............................................................................................................................ 27

5.2 Alarm reset ....................................................................................................................... 28

5.3 Parameter initialization ..................................................................................................... 29

5.4 Digital signal forced input and output function ................................................................ 30

5.5 Offline inertia identification ............................................................................................. 32

Chapter 6: Troubleshooting ............................................................................................................ 35

6.1 Fault diagnosis and treatment ........................................................................................... 35

6.1.1 Non-resettable NO.1 fault ...................................................................................... 36

6.1.2 Resettable NO.1 fault ............................................................................................. 36

6.1.3 Resettable NO.2 fault ............................................................................................. 37

6.2 Reasons for warning and treatment .................................................................................. 37

Chapter 7: Parameter List ............................................................................................................... 39

P00 group: basic control parameters ............................................................................... 40

P01 group: servo motor parameters ................................................................................ 42

P02 group: digital terminal input and output parameters ................................................ 42

P04 group: position control parameters .......................................................................... 46

P05 group: speed control parameters .............................................................................. 47

P06 group: torque control parameters ............................................................................. 48

P07 group: gain parameter .............................................................................................. 50

P09 group: failure and protection ................................................................................... 52

P11 group: auxiliary function parameters ....................................................................... 53

P12 group: keyboard display parameters ........................................................................ 54

P13 group: multi-segment position ................................................................................. 54

P14 group Multi-speed command ................................................................................... 59

P16 group: special function parameters .......................................................................... 65

P18 group: display parameters ........................................................................................ 67

DIDO assignment basic function definition.................................................................... 69

Appendix A: Error Code Table....................................................................................................... 71

Appendix B: Version Change Record ............................................................................................ 73