Moog MSD User manual

moog

MSD Servo Drive

User Manual

Single-Axis System

Multi-Axis System

Compact

moog MSD Servo Drive User Manual Profibus

Profibus for MSD Servo Drive user manual

Id. no.: CA65645-001, Rev. 2.0

Da te : 0 8 / 20 11

We reserve the right to make technical changes.

Technical alterations reserved.

The contents of our documentation have been compiled with greatest care and in com-

pliance with our present status of information.

Nevertheless we would like to point out that this document cannot always be updated

parallel to the technical further development of our products.

Information and specifications may be changed at any time. For information on the

latest version please refer to drives-support@moog.com.

This document details the functionality of the following equipment variants:

MSD Servo Drive Single-axis system

MSD Servo Drive Multi-axis system

MSD Servo Drive Compact

moog MSD Servo Drive User Manual Profibus 3

Table of contents

How to use this manual.................................................................. 5

1 General ................................................................................... 7

1.1 Measures for your Safety ........................................................................................7

1.2 Introduction to Profibus ..........................................................................................7

1.3 System requirements...............................................................................................7

1.4 Further documentation ...........................................................................................8

2 Commissioning the Profibus Interface....................................... 9

2.1 Connections and user controls................................................................................9

2.2 Plug configuration for the P

rofibus

cable..................................................................9

2.3 Bus termination.......................................................................................................10

2.4 Setting the drive address.........................................................................................10

2.5 Operating displays ..................................................................................................11

2.6 GSD file...................................................................................................................11

3 Cyclic data transmission – DPV0 ............................................. 13

3.1 Parameter process data objects (PPO) .....................................................................13

3.1.1 Standard “PROFIdrive” telegrams ................................................................13

3.1.2 User-specific PPOs .......................................................................................15

3.1.3 PKW parameter channel ..............................................................................19

3.2 Master control word ...............................................................................................20

3.2.1 Jog mode speed mode ................................................................................21

3.2.2 Jog mode positioning mode ........................................................................22

3.2.3 Jog mode reference value parameter ...........................................................22

3.3 Drive status word....................................................................................................22

3.4 Drive status machine...............................................................................................24

4 Acyclic data transmission – DPV1 ........................................... 27

4.1 Examples of request and reply telegrams ................................................................32

5 Operating modes................................................................... 35

5.1 Speed Control.........................................................................................................35

5.2 Speed control circuit and associated control parameters .........................................36

5.3 Position control.......................................................................................................37

5.4 Position control circuit and associated control parameters ......................................39

6 Homing ................................................................................. 41

6.1 Homing runs performed by the drive ......................................................................41

6.2 Homing run speed ..................................................................................................41

6.3 Homing run acceleration.........................................................................................41

6.4 Zeroing offset .........................................................................................................41

6.5 Homing cams, limit switches...................................................................................41

6.6 Homing run methods..............................................................................................43

7 Examples of commissioning using manufacturer-specific

telegrams .............................................................................. 45

7.1 Position control using PPO 5 ...................................................................................45

7.2 Conversion of reference values and actual values using factor group parameters....46

7.3 Examples for setting the user factor group..............................................................48

7.4 Speed control using PPO 2 ......................................................................................48

7.4.1 Speed input .................................................................................................49

7.5 Mappable parameters.............................................................................................50

8 Profibus parameters............................................................... 51

9 Appendix Glossary................................................................. 53

moog MSD Servo Drive User Manual Profibus 4

moog MSD Servo Drive User Manual Profibus 5

How to use this manual

Dear user!

This manual is intended for use by project engineers, commissioning engineers and pro-

grammers of drives and automation solutions involving the Profibus fieldbus.

It assumes that you have received appropriate training on Profibus and that you have

access to relevant reference books. We assume that your drive has already been commis-

sioned – if not, please first refer to the user manual.

11 General

44 Acyclic data transmission - DPV1

55 Operating modes

66 Homing

Appendix: Glossary, key words directory

33 Cyclic data transmission - DPV0

22 Commissioning the Profibus interface

77 Commissioning examples

88 Profibus parameters

moog MSD Servo Drive User Manual Profibus 6

Pictograms

Attention! Incorrect operation may damage the drive or cause it to malfunc-

tion.

Danger from electrical tension! Improper conduct may endanger human life.

Danger from rotating parts! The drive may start up automatically.

Note: Useful information

moog MSD Servo Drive User Manual Profibus 7

[ Kapitel 1 ]

1 General

1.1 Measures for your Safety

Servo controllers of the MSD Servo Drive family are quick and easy to handle. For your

own safety and for the safe functioning of your device, please be sure to observe the

following points:

Read the Operating Manual first!

1.

• Follow the safety instructions!

Electric drives are subject to certain hazards:

• Electric voltages > 230 V/460 V:

Dangerously high voltages may still be present 10 minutes after the power

is switched off. so always make sure the system is no longer live!

• Rotating parts

• Hot surfaces

Your qualification:

• In order to prevent personal injury or damage to property, only personnel

with electrical engineering qualifications may work on the device.

• Knowledge of the national accident prevention regulations (such as VBG4

in Germany)

• Knowledge of structure and networking using the CAN fieldbus

U

V

N

L+

RB

L-

L3

L2

L1

U

V

N

L+

RB

L-

L3

L2

L1

During installation observe the following instructions:

• Always comply with the connection conditions and technical specifications.

• Standards for electrical installation, e.g. cable cross-sections, screening etc.

• Do not touch electronic components and contacts (electrostatic discharge

may destroy components)

1.2 Introduction to Profibus

The Profibus implementation in MSD Servo Drive is based on the PROFIdrive profile

“Profibus PROFdrive profile version 4.0” dated August 2005.

Performance features in key words

–Data transmission using two-wire twisted pair cable (RS 485)

–Transmission rate: optionally 9.6 K, 19.2 K, 45.45 K, 93.75 K, 187.5 K, 500 K,

1.5 M, 3 M, 6 M or 12 MBaud

–Automatic Baud rate detection

–Profibus address can be set using the rotary coding switches or alternatively

using the addressing parameters

–Cyclic data exchange reference and actual values using DPV0

–Acyclic data exchange using DPV1

–Synchronisation of all connected drives using freeze mode and sync mode

–Reading and writing drive parameters using the PKW channel or DPV1

1.3 System requirements

It is assumed that you have access to a standard Profibus set-up program or a Profibus

interface driver.

moog MSD Servo Drive User Manual Profibus 8

1.4 Further documentation

•User manual for commissioning the drive device

•User manual for further parameterisation to customise the application.

•The User Manual can be downloaded as a PDF file from the Product DVD, which is

enclosed the MSD Servo Drive.

•CiA 301 (Rev. 4.0): Application Layer and Communication Profile

•CiA 402 (Rev. 2.0): Device Profile Drives and Motion Control

•Profibus User Organisation „Profidrive - Profil Drive Technology for Profibus and

Profinet“ Version 4.1, May 2006, Order no. 3.172

moog MSD Servo Drive User Manual Profibus 9

[ Chapter 2 ]

2 Commissioning the

Profibus Interface

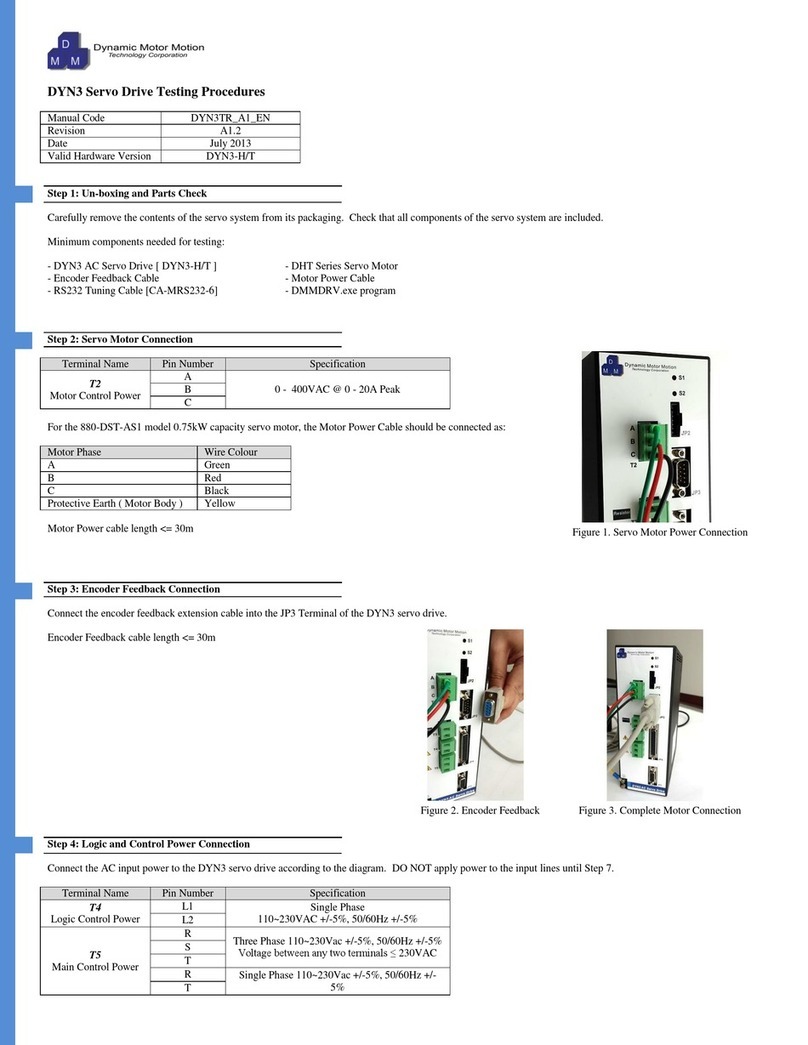

2.1 Connections and user controls

The connections and user controls for the Profibus interface are shown schematically

in Figure 2-1. The LEDs H1, H2, H3 act as status indicators. The rotary coding switches

S1 and S2 can be used to set the Profibus address for the drive. The Profibus cable is

connected to the plug X14.

Front plate No. Comments

H1 LED for status indication (yellow)

H2 LED for status indication (red)

H3 LED for status indication (green)

S1 Rotary coding switch for setting the Profibus address for the

drive = 0x(S2)(S1)

S2 Rotary coding switch for setting the Profibus address for the

drive = 0x(S2)(S1)

X14 Profibus cable connection

Table 2.1 Profibus options card

2.2 Plug configuration for the Profibus cable

The Profibus is connected using a nine-pin sub-D plug. The pin assignment is shown in

Fig. 2-2 and described in Table 2.1.

Figure 2.1

X14

12345

6789

RxD

TxD-P DGND

RxD

TxD-N

VP

5 Volt

Pin assignment of sub-D-plug connector

PIN RS-485 Signal Description

1SHIELD Earthed shield

2RP Reserved for power supply via the bus

3B/B’ (red) RxD / TxD-P Send and receive data (+)

4CNTR-P Control signal for repeater (+)

5C/C’ DGND Data reference potential and power supply to

terminating resistor (-)

6VP Power supply for terminating resistor (+)

7RP Reserved for power supply via the bus

8A /A’ ( gr ee n) RxD / TxD-N Send and receive data (-)

9CNTR-N Control signal for repeater (-)

Table 2.2 Description of pin assignment

The pin assignments shown with dark backgrounds in the table are not necessary from

the user’s point of view. The control signals used for the repeaters are optional, and the

power supply for the terminating resistors is provided by the device.

moog MSD Servo Drive User Manual Profibus 10

2.3 Bus termination

If the servo controller is initially at the end of the bus system, a plug with an integral

terminating resistor Rt should be used. In addition to the cable terminating resistor in ac-

cordance with the EIA-485 standard, a pull-down resistor Rd against the data reference

potential DGND and a pull-up resistor Ru against VP are provided. This ensures a defined

no-load potential of 1.1 Volt between pins 3 and 8. In a made-up Profibus cable these

resistors are all incorporated as standard in the Profibus plug and the terminating resistor

can be activated using a switch on the Profibus plug. The following figure shows a Sub-

D 9-pin plug bus termination.

Figure 2.2

Plug Profibus cable

Device

Vp = 5 Volt (6)

RxD TxD-P (3)

RxD TxD-N (8)

GND (6)

Ru = 390 Ohm

Rt = 220 Ohm

Rd = 390 Ohm

B (red)

A (green)

Sub-D 9-pin plug bus termination

2.4 Setting the drive address

The drive address can be set as standard using the rotary coding switches on the options

card (see Fig. 2-1). The address range runs from 0 to 125. The drive address is not loaded

until a 24 Volt reset has been applied to the device.

The drive address can also be assigned using parameter P 0918 COM_DP_Address.

For this purpose the rotary coding switches must be set to value in excess of 125.

The drive address set by software address is not loaded until a 24 Volt reset has been

applied to the device.

In the MSD Servo Drive Compact the address cannot be set using the switches.

On all devices the bus address can also be set using the buttons on the device, see ope-

rating instructions for MSD Servo Drive Compact.

Diagnostics can be performed on the MSD Servo Drive Compact using the internal

control unit in the device. The control unit comprises the following elements that are all

positioned on the front:

•2-digit 7-segment display (1, 2)

•2 buttons (3, 4)

Figure 2.3

1

2

3

4

Integrated control unit MSD Servo Drive Compact

moog MSD Servo Drive User Manual Profibus 11

[ Chapter 2 ]

The following functions and indications are available:

•Indication of the device status

The device status is indicated after switching on the control supply. If an entry is

not made using the buttons for 60 seconds, the display returns to the display of

the device status.

•Indication of the device error status

On the occurrence of an error in the device, the display is immediately switched to

the indication of the error code.

•Parameter setting (indication „PA“)

Reset the device parameter settings to the factory setting

•Ethernet IP address setting (indication „IP“)

Setting for the Ethernet IP address as well as the subnet mask

•Fieldbus settings (indication „Fb“)

Setting e.g. for the fieldbus address

2.5 Operating displays

Options module: Three LEDs are mounted on the options card; these give indications

regarding the current operating status of the module. In Tables 2-2 and 2-3 the opera-

ting statuses of the Profibus module are listed, based on the various LED illumination

combinations.

LED 1, green LED 2, red Status

Reset (after switching on)

ASIC RAM test and initialisation

End of ASIC RAM test and initialisation

Table 2.3 Selftest during diagnostic

LED 1, green LED 2, red Status

Seeking Baud rate after switching on without bus

connection

Seeking Baud rate after the bus connection has

already been established

Awaiting parameterisation data

Table 2.4 Operation diagnostics

LED 1, green LED 2, red Status

Communication: Data exchange without acyclic

master class 2 connection. Yellow LED lights up.

Communication: Data exchange “clear state”

Incorrect parameterisation data

Incorrect configuration data

Communication: Data exchange with acyclic

master class 2 connection.

Table 2.4 Operation diagnostics

LED 3, yellow Status

Device is exchanging data

Table 2.5 Data exchange

2.6 GSD file

The device master data file contains the summary of the device features in a standar-

dised form. The device features include for instance the device name, the bus timing,

the extended services available and the modules that can be selected (telegram types).

In order to use different telegram types, the GSD file must be linked in at the configura-

tion phase of the Profibus network. This file contains, as well as the standard “Profidrive

Profile” telegrams, additional manufacturer-specific telegram types.

moog MSD Servo Drive User Manual Profibus 12

moog MSD Servo Drive User Manual Profibus 13

[ Chapter 3 ]

3 Cyclic data transmission –

DPV0

3.1 Parameter process data objects (PPO)

The establishment of communications between a class 1 master and the

MSD Servo Drive servo controller is essentially performed in three phases. Firstly the

MSD Servo Drive is parameterised with the current bus parameters, monitoring times

and drive-specific parameters (phase 1). In the configuration phase a configuration sent

by the master is compared with the actual MSD Servo Drive configuration (phase 2).

Once these two phases have been completed successfully, the cyclic user data traffic

starts (phase 3).

The various telegram types (Parameter Process Data Objects - PPO) are prepared in the

GSD file. These PPOs form the basis of the configuration phase. The project engineer

knows from the GSD file how many bytes are required for the input and output data for

Profibus communication between the master and the servo controller and can use this

information to perform his settings in the configuration tool. As well as the standard

telegrams in accordance with the “PROFIdrive – Profile”, there are additional user-

specific telegram types. In addition to the PZD process data channel, the user-specific

telegram make partial use of a PKW parameter channel.

3.1.1 Standard “PROFIdrive” telegrams

The table below lists firstly the standard “Profidrive” telegrams that are supported by the

servo controller. Table 3-1 explains the abbreviations used to assign standard telegrams

to a specific process data channel. The process data channel (abbreviated to PZD) is

grouped by words.

Abbreviation Name Number of words

STW1 Control word 1 1

STW2 Control word 2 1

ZSW1 Status word 1 1

ZSW2 Status word 2 1

NSOLL_A Speed reference 1

NIST_A Actual speed 1

SATZ ANW Set selection (from the driving set table) 1

AKTSAT Z Current set selection (from the driving set

table)

1

XSOLL_A Reference position 2

XIST_A Actual position 2

TARPOS_A Reference destination position 2

VELOCIT Y_ A Reference speed 2

Figure 3.1 Abbreviations

Standard telegram 1 is a defined telegram type for speed control. It consists of two input

words and two output words as shown in the following table.

PZD number 1 2

Reference values STW1 NSOLL_A

PZD number 1 2

Actual values ZSW1 NIST_ A

Table 3.1 Standard telegram 1

Standard telegram 7 is a defined telegram type for selecting the driving set. In total 16

driving sets saved in the drive can be selected. The telegram type comprises 2 input

words and two output words as in the following table.

PZD number 1 2

Reference values STW1 SAT ZANW

PZD number 1 2

Actual values ZSW1 AKTSATZ

Table 3.2 Standard telegram 7

moog MSD Servo Drive User Manual Profibus 14

Standard telegram 8 is a defined telegram type for positioning with the facility for spe-

cifying a positioning speed. It consists of 5 input words and 5 output words as shown in

the following table.

PZD number 12345

Reference values XSOLL_A STW2 NSOLL_A

PZD number 12345

Actual values XIST_A ZSW2 NIST_A

Table 3.3 Standard telegram 8

Standard telegram 9 is a defined telegram type for positioning. It consists of 6 input

words and five output words as shown in the following table.

PZD number 123456

Reference values STW1 TARPOS_ A STW2 VELOCITY_A

PZD number 12345

Actual values ZSW1 XIST_A ZSW2 NIST_ A

Table 3.4 Standard telegram 9

Every standard telegram in the device is described in the GSD file by a PROFIdrive Profile

configuration identifier (ID). The following table shows these identifiers for the selected

standard telegrams.

Telegram type Data area Identifier (ID)

Standard telegram 1 2 output words and 2 input words 0xC3 0xC1 0xC1 0xFD 0x00 0x01

Standard telegram 7 2 output words and 2 input words 0xC3 0xC1 0xC1 0xFD 0x00 0x07

Standard telegram 8 5 output words and 5 input words 0xC3 0xC4 0xC4 0xFD 0x00 0x08

Standard telegram 9 6 output words and 5 input words 0xC3 0xC5 0xC4 0xFD 0x00 0x09

Table 3.5 Identifier

moog MSD Servo Drive User Manual Profibus 15

[ Chapter 3 ]

3.1.2 User-specific PPOs

As well as the standard telegrams that are supported there are in addition further user-

specific PPOs (Parameter Process data Objects). The following PPOs are also transmitted

cyclically and in addition to the PZD process data channel partially contain a PKW para-

meter channel, thereby allowing access to the drive parameter values.

PPO PKW PZD

1PKE IND PKW

1

PKW

2

STW/

ZSW

REFERENCE VALUE/

ACTUAL VALUE

--------

2PKE IND PKW

1

PKW

2

STW/

ZSW

REFERENCE VALUE/

ACTUAL VALUE

PZD

3

PZD

4

PZD

5

PZD

6

----

3* - - - - STW/

ZSW

REFERENCE VALUE/

ACTUAL VALUE

--------

4 - - - - STW/

ZSW

REFERENCE VALUE/

ACTUAL VALUE

PZD

3

PZD

4

PZD

5

PZD

6

----

5PKE IND PKW

1

PKW

2

STW/

ZSW

REFERENCE VALUE/

ACTUAL VALUE

PZD

3

PZD

4

PZD

5

PZD

6

PZD

7

PZD

8

PZD

9

PZD

10

- - - - STW/

ZSW

REFERENCE VALUE/

ACTUAL VALUE

PZD

3

PZD

4

------

PKE IND PKW

1

PKW

2

STW/

ZSW

REFERENCE VALUE/

ACTUAL VALUE

PZD

3

PZD

4

------

- - - - STW/

ZSW

REFERENCE VALUE/

ACTUAL VALUE

PZD

3

PZD

4

PZD

5

PZD

6

PZD

7

PZD

8

- -

PKE IND PKW

1

PKW

2

STW/

ZSW

REFERENCE VALUE/

ACTUAL VALUE

PZD

3

PZD

4

PZD

5

PZD

6

PZD

7

PZD

8

- -

- - - - STW/

ZSW

REFERENCE VALUE/

ACTUAL VALUE

PZD

3

PZD

4

PZD

5

PZD

6

PZD

7

PZD

8

PZD

9

PZD

10

(*) PPO3 is the standard telegram 1

Table 3.6 User-specific Parameter Process data Objects

moog MSD Servo Drive User Manual Profibus 16

In the drive parameter list there exist two signal tables, which contain all the process

data that can be cyclically read and written for the Profibus communications DPV0. All

possible process data signals that can be written can be found in the signal table

P 1284 COM_DP_SignalList_Write and all possible process data signals that can be read

can be found in the signal table P 1285 COM_DP_SignalList_Read. The most important

parameters that can be read and written are also documented in Chapter 6.

The process data signals that can be written can be configured in the signal table

P 0915 COM_DP_PZDSelectionWrite. The number of process data available to be written

are determined by the PPO type that is selected.

The process data signals that can be read can be configured in the signal table

P 0916 COM_DP_PZDSelectionRead. The number of process data available to be read are

also determined by the PPO type that is selected.

When using standard telegrams the process data signals in the signal tables are automa-

tically configured by the firmware.

A maximum of 15 process data signals can be „mapped“. Here both words and double

words can be used.

The user-specific drive telegram types are described by a configuration identifier (ID) in

the GSD file. This describes the structure of the cyclic report data using a special identifi-

cation format shown in the figure below.

Figure 3.2 Identification format (Identifier)

After the parameterisation phase, the master sends the drive a configuration telegram

containing this special identification (ID). On receipt of this, the drive compares the data

in the configuration telegram with the configuration held in the drive. The identifier

determined by the PPO type can be found in the GSD file under the heading “Modules”.

The following table shows these identifiers for the user-specific telegrams.

Length of the data

00 = 1 byte/word

15 = 16 bytes/words

Input/Output

00 = specic identication format

01 = input

10 = output

11 = input/output

0 = byte, 1 = word

0 = consistency over byte/word

1 = consistency over the overall

length

moog MSD Servo Drive User Manual Profibus 17

[ Chapter 3 ]

PPO

type

Identifier

(ID) Hex

Identifier

(ID) Bin Evaluation using the special identification format (Figure 3.6) Reference to Table AK

slave-master

10xF3

0xF1

1111 0 011

1111 0 0 0 1

4 words input/output data (consistent overall length)2 words input/output

data (consistent overall length) PKW channel

20xF3

0xF5

1111 0 011

1111 0101

4 words input/output data (consistent overall length)6 words input/output

data (consistent overall length) PZD channel

30xF1 1111 0 0 0 1 2 words input/output data (consistent overall length) PKW channel

40xF5 1111 0101 6 words input/output data (consistent overall length) PZD channel

50xF3

0xF9

1111 0 011

1111 1 0 01

4 words input/output data (consistent overall length)10 words input/output

data (consistent overall length) PZD channel

0xF3 1111 0 011 4 words input/output data (consistent overall length) PZD channel

0xF3

0xF3

1111 0 0 11

1111 0 0 11

4 words input/output data (consistent overall length)4 words input/output

data (consistent overall length) PKW channel

0xF7 1111 0111 8 words input/output data (consistent overall length) PZD channel

0xF3

0xF7

1111 0111

1111 0111

4 words input/output data (consistent overall length)8 words input/output

data (consistent overall length) PZD channel

0xF9 1111 1 0 01 10 words input/output data (consistent overall length) PKW channel

0xC0

0xCD

0xCD

14 words input/output data (consistent overall length) PZD channel

0xF3

0xC0

0xCD

0xCD

14 words input/output data (consistent overall length) PZD channel

0xC0

0xD1

0xD1

18 words input/output data (consistent overall length) PKW channel

0xF3

0xC0

0xD1

0xD1

18 words input/output data (consistent overall length) PZD channel

0xC0

0xD5

0xD5

22 words input/output data (consistent overall length) PZD channel

0xF3

0xC0

0xD5

0xD5

22 words input/output data (consistent overall length) PKW channel

Table 3.7 Listing of identifiers

moog MSD Servo Drive User Manual Profibus 18

PPO

type

Identifier

(ID) Hex

Identifier

(ID) Bin Evaluation using the special identification format (Figure 3.6) Reference to Table AK

slave-master

0xC0

0xD9

0xD9

26 words input/output data (consistent overall length)

0xF3

0xC0

0xD9

0xD9

26 words input/output data (consistent overall length) PKW channel

0xC0

0xDD

0xDD

30 words input/output data (consistent overall length)

0xF3

0xC0

0xDD

0xDD

30 words input/output data (consistent overall length) PKW channel

Table 3.7 Listing of identifiers

moog MSD Servo Drive User Manual Profibus 19

[ Chapter 3 ]

3.1.3 PKW parameter channel

Some PPOs offer an additional cyclic parameter channel. This channel allows drive

parameters to the read and written.

PKW

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte

PKE (1 word) IND (1 word) PKW1 (1 word) PKW2 (1 word)

The parameter consists of a total of 4 words: the parameter identifier PKE (1 word), the

sub-index IND (1 word) and the parameter identification word, which occupies the data

area PKW1 (1 word) to PKW2 (1 word). The parameter identification is shown by bits in

the following table.

AK PNU

15 14 13 12 11 10 9876543210

AK Request or reply identification (value range 0..15)

PNU Parameter number (value range 1…4095)

Table 3.8 PKE parameter identification

The following tables list the request identification (master) and the reply identification

(slave).

Request identification Function

0No request

1Request parameter value

2Change parameter value (word)

3Change parameter value (double word)

4Read parameter description

5 -

6Request parameter value (array)

7Change parameter value (array) (word)

8Change parameter value (array) (double word)

Table 3.9 Request identification AK (master slave)

Reply identification Function

0No reply

1 Parameter value sent (word)

2 Parameter value sent (double word)

3Parameter description sent

4 Parameter value (array) sent (word)

5 Parameter value (array) sent (double word)

6 –

7 Request not executable, see error no.

Table 3.10 Reply identification AK (Slave Master)

On reply identification 7 the error number sent to the drive from the master is shown in

the area PKW1 to PKW2. The following table lists these error numbers.

Error Statement

0Impermissible PNU

1Parameter cannot be changed

2 Lower or upper parameter value limit transgressed

3 Defective sub-index

4 Not an array

5Incorrect data type

...

17 Request cannot be executed because of the operating status

18 Other error

Table 3.11 Reply identification AK (Slave Master)

In addition request identification 4 can be used to read a parameter description. The

parameter description receives relevant information regarding the respective parameter.

The following table shows the sub-indexes that can be used to access the individual

parameter structure elements. The sub-index is indicated only by byte 3.

Sub-index Meaning Data type

1Identifier (ID) V2

2Number of field elements or string length Unsigned 16

Table 3.12 Parameter description

moog MSD Servo Drive User Manual Profibus 20

Sub-index Meaning Data type

3Standardisation factor Floating Point

4Variable attributes OctetString 2

5Reserved OctetString 4

6 Name (only the first four bytes are sent) VisibleString 16

7Lower limit value OctetString 4

8 Upper limit value OctetString 4

9Reserved OctetString 2

10 ID extension extension V2

11 PZD reference parameter Unsigned 16

12 PZD standardisation V2

Table 3.12 Parameter description

The identifier (sub-index 1) in the parameter description identifies additional characteris-

tics of the respective parameter. Table 3-8 describes the meaning of the identifier.

Bit Meaning Explanation

15 Reserved

14 Array

13 Parameter value can only be reset If this bit is set, the respective parameter

value can be varied externally only so as to

be set to zero

12 Parameter value was changed to a value

different from the factory settings

If this bit is set, the parameter value is

different from the factory settings

11 Reserved

10 Additional text array can be called up

9 Parameter cannot be written

8Standardisation factor and variable attri-

butes not relevant

This bit is set if the parameter is of a data

type that cannot be used to calculate any

physical values (e.g. data type string)

0 - 7 Data type of the parameter value (value =

“Profi-Drive table 9”)

Table 3.13 Structure of the identifier

3.2 Master control word

Bit Operating mode: Speed Control Operating mode: Positioning control

Bit 15

(MSB)

0Apply relative positioning immedia-

tely after start enable

1Speed mode

Bit 14

0Normal positioning

1Speed mode

Bit 13

0 Not used New reference values activated by toggling the

master control word bit 6

1 Not used New reference values are loaded directly

Bit 12

0 Not used Positioning reference value = absolute

1 Not used Positioning reference value = relative

Bi t 11

0 Not used Stop homing run

1 Not used Start homing run

Bit 10

0 No access rights over the PLC

1 Access rights over the PLC

Bit 9

0 Jog mode 2 off Jog mode 2 off

1 Jog mode 2 on Jog mode 2 on

Bit 8

0 Jog mode 1 off Jog mode 1 off

1 Jog mode 1 on Jog mode 1 on

Bit 7

0Error acknowledgement at rising flank 0 1

1

Table 3.14 Master control word

Other manuals for MSD

3

Table of contents

Other Moog Servo Drive manuals

Popular Servo Drive manuals by other brands

SYNAPTICON

SYNAPTICON SOMANET Circulo 7 manual

Inovance

Inovance SV670P Series troubleshooting guide

Rockwell Automation

Rockwell Automation Allen-Bradley Kinetix 5500 Series user manual

Moons'

Moons' SS03-S-A Hardware manual

ABB

ABB ACQ580-01 Series Quick installation and start-up guide

Oriental motor

Oriental motor BX Series operating manual

AutoVac

AutoVac VACUUM IQ C2000 Series quick start guide

GEZE

GEZE E 170/230 V AC Wiring diagram

DMM

DMM DYN3 Installation, Commissioning, and Testing Procedures

Delta Electronics

Delta Electronics ASDA-A Series user manual

Copley Controls

Copley Controls Xenus PLUS Compact CANopen Series manual

YAKO

YAKO ES2 Series user manual