moog MSD Servo Drive DC-AC Operation Manual 7

to glossary

Id.-No.: CA97554-001 Date: 06/2012

Table of contents

1 Safety.............................................................................................9

1.1 For your safety ........................................................................................................... 9

1.1.1 Read the Operation Manual first! .................................................................. 9

1.1.2 Warning symbols used..................................................................................10

1.2 Intended use .............................................................................................................10

1.3 Responsibility ............................................................................................................10

2 Mechanical installation ................................................................. 11

2.1 Notes for installation .................................................................................................11

2.2 DC-AC servo drive installation Air-cooled housing .....................................................12

2.3 DC-AC servo drive installation Liquid-cooled housing................................................14

2.4 Alignment and arrangement in a group.....................................................................16

2.5 Cooling circuit connection.........................................................................................18

3 Electrical installation .....................................................................19

3.1 Notes for installation .................................................................................................19

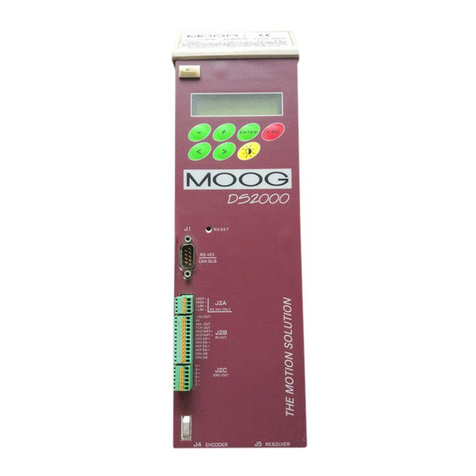

3.2 Overview of connections Size 1 to Size 4...................................................................20

3.3 Overview of connections Size 5 and Size 6A............................................................. 22

3.4 Protective conductor connection...............................................................................24

3.5 Electrical isolation method ........................................................................................24

3.6 Connection of supply voltage....................................................................................26

3.6.1 Connection of control supply (+24VDC)......................................................26

3.6.2 DC power supply connection........................................................................27

3.7 Control connections ..................................................................................................29

3.7.1 Specification of control connections .............................................................29

3.7.2 Brake driver ................................................................................................. 30

3.8 Specification of USB port...........................................................................................31

3.9 Specification of Ethernet port....................................................................................31

3.10 Option1....................................................................................................................31

3.11 Option2....................................................................................................................31

3.12 Encoder connection...................................................................................................32

3.12.1 Encoder connection of servo motors ............................................................32

3.12.2 Matching motor/encoder cable to servo drive ...............................................32

3.12.3 Ready made-up encoder cables ....................................................................33

3.12.4 Resolver connection......................................................................................33

3.12.5 Connection for high-resolution encoders..................................................... 34

3.13 Motor connection .....................................................................................................35

3.13.1 Connection of synchronous motors ..............................................................35

3.13.2 Ready made-up motor cable........................................................................ 36

3.13.3 Switching in the motor cable ....................................................................... 36

4 Commissioning.............................................................................37

4.1 Notes for operation ...................................................................................................37

4.2 Initial commissioning .................................................................................................37

4.2.1 Switching on control voltage ....................................................................... 38

4.2.2 Connecting the PC and servo drive.............................................................. 38

4.2.3 Parameter setting ........................................................................................ 38

4.2.4 Controlling the drive with Moog DriveADministrAtor5 .................................. 38

4.3 Serial commissioning ................................................................................................ 40

4.4 Integrated operator control unit and MMC card........................................................41

4.4.1 Functions of buttons T1 and T2 ....................................................................42

4.4.2 Display..........................................................................................................42

4.4.3 Parameter menu (PA)....................................................................................43

4.4.4 Ethernet IP address menu (IP) ...................................................................... 44

4.4.5 Fieldbus address menu (Fb)...........................................................................45

4.4.6 Firmware update with MMC card................................................................ 46