For Service Engineer

Service Information

SI1604009E-002= S20, S10, M20, M10 and D10 installation procedures

2/34

Table of contents

1. Machine installation requirements..................................................................................................3

2. Confirmations before shipping........................................................................................................4

3. Carry in machines & equipment and level the machine................................................................5

3.1 Confirmations before carrying-in......................................................................................................5

3.2 Unload the machines and equipment...............................................................................................5

3.3 Carry in machines and equipment ...................................................................................................6

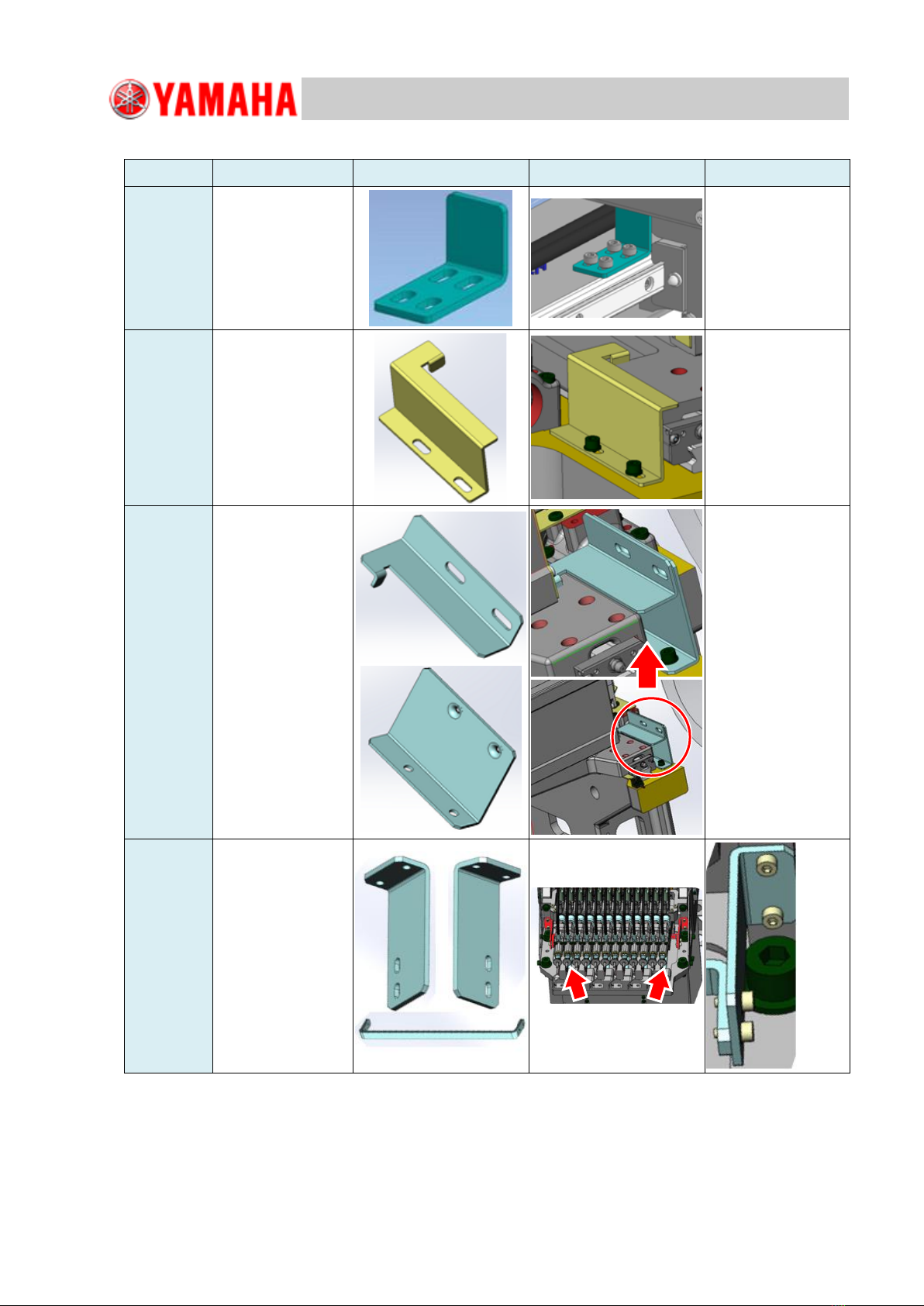

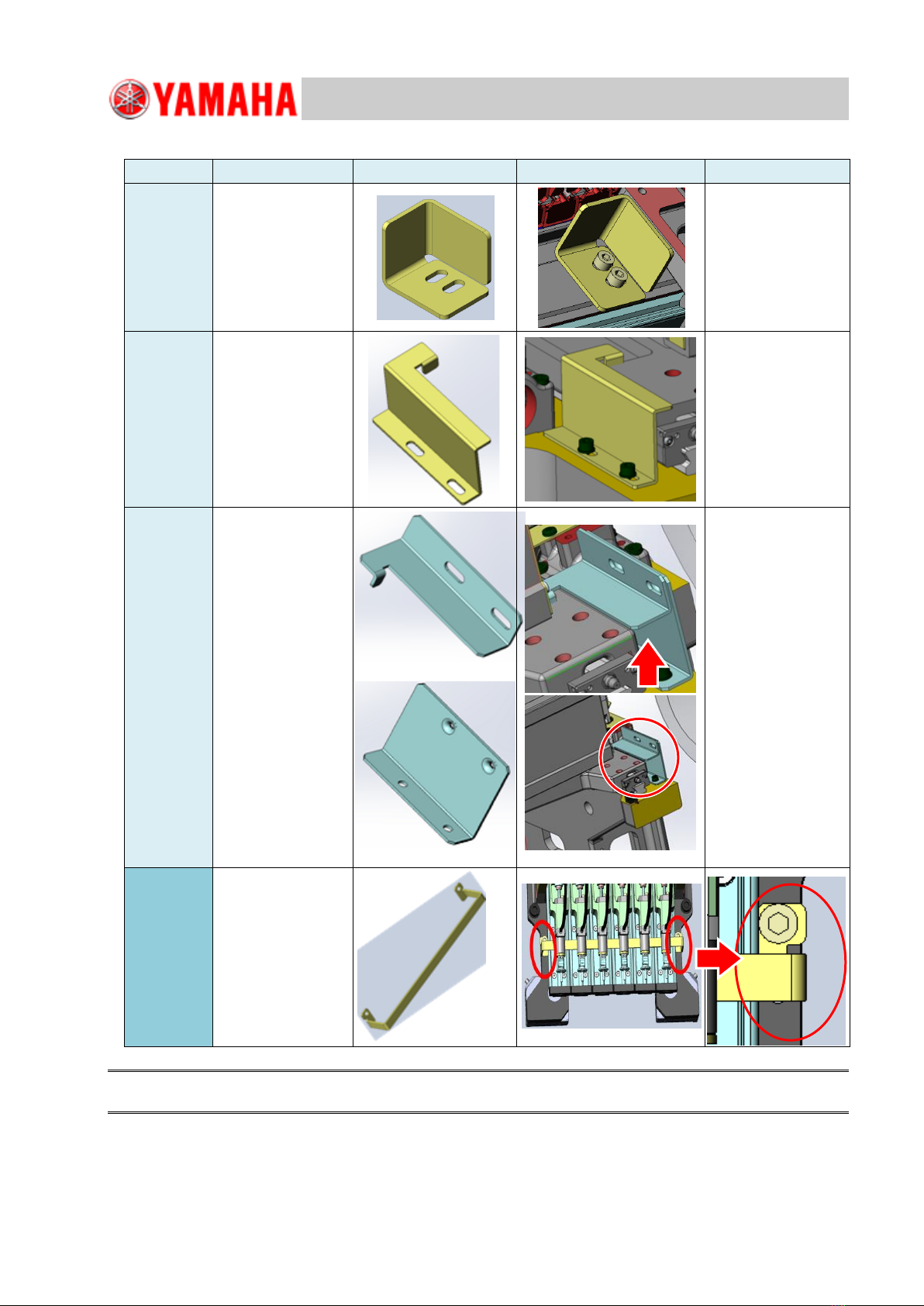

3.4 Remove the shipping brackets.........................................................................................................6

3.5 Preparation before marking............................................................................................................11

3.6 Install the machines temporarily.....................................................................................................12

3.7 Level the machine..........................................................................................................................13

3.7.1 Coarse adjustment..................................................................................................................13

3.7.2 Jack and sliding paper............................................................................................................14

3.7.3 Jack setting positions of the machine.....................................................................................14

3.7.4 Place a jack ............................................................................................................................16

3.7.5 Position the machine ..............................................................................................................17

3.8 Correction and adjustment of levelness.........................................................................................18

3.8.1 Check the X-beam torsion......................................................................................................18

3.8.2 Case if the torsion is large......................................................................................................19

3.9 Lock adjuster bolts and support legs..............................................................................................20

4. Setup after installing the machine.................................................................................................22

4.1 Install accessories..........................................................................................................................22

4.2 Install the LCD monitor and the balancer.......................................................................................22

4.2.1 Previous LCD monitor.............................................................................................................22

4.2.2 Current LCD monitor...............................................................................................................23

4.3 Air and power connection...............................................................................................................24

4.3.1 Connect the air and power to the machine.............................................................................24

4.3.2 Check and adjust the air pressure..........................................................................................25

4.4 Confirm the PCB transfer...............................................................................................................26

5. Reference.........................................................................................................................................27

5.1 Unload the machine by suspending...............................................................................................27

5.2 The effects caused by the slanted floor ............................................................................................28

5.2.1 The material and the load capacity of the floor ......................................................................29

5.3 Condensation on the machine ..........................................................................................................30

5.3.1 The formation process of condensation on the machine..............................................................30

5.3.2 How to prevent condensation from forming on the machine ........................................................32

5.3.3 When condensation occurs...........................................................................................................32

6. Revision history ..............................................................................................................................34