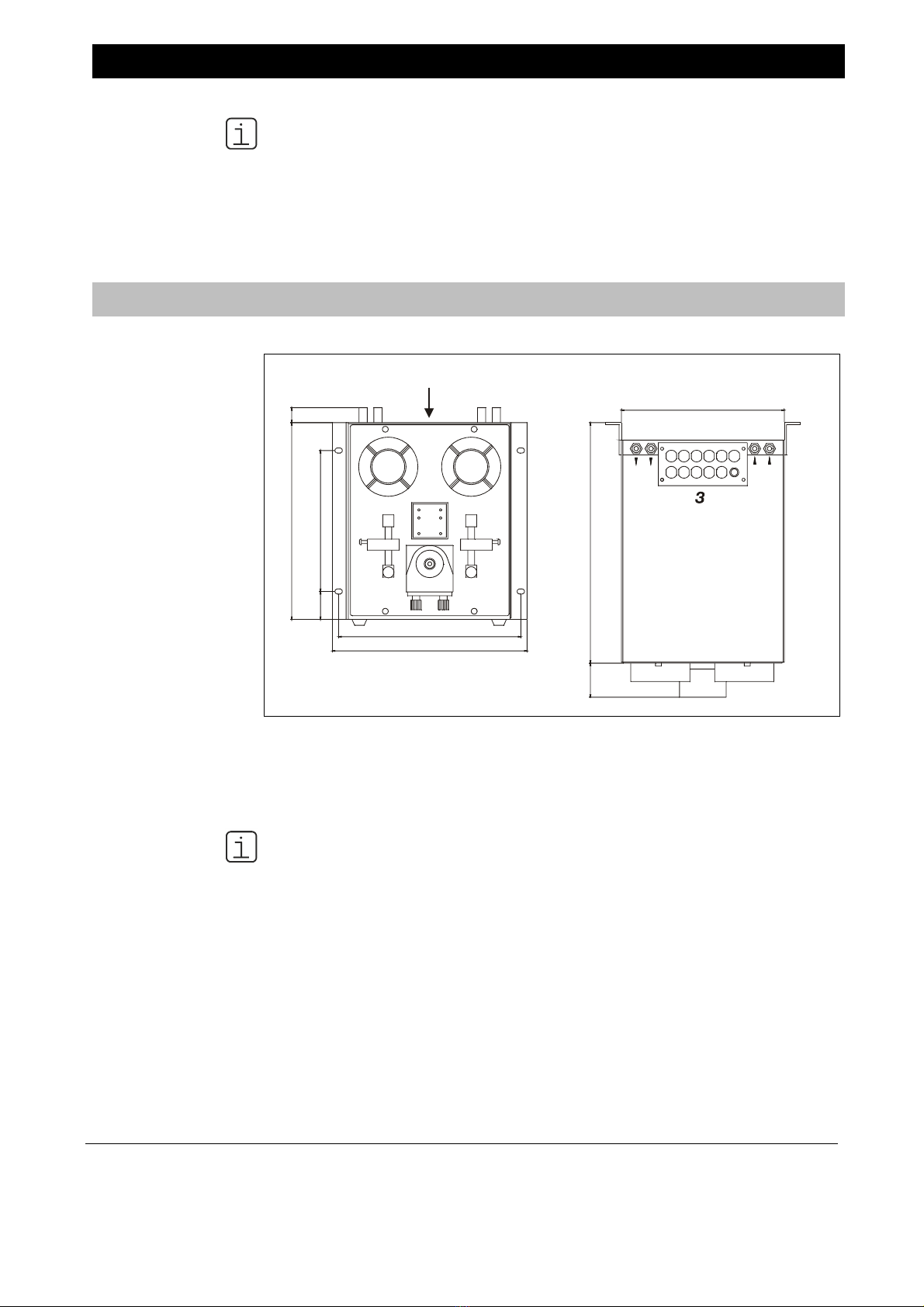

4 SCC-F Sample gas feed unit Operator’s manual 42/23-51 EN Rev. 3

Chapter 1 Safety information

Intended application, instrument designs

Intended application The SCC-F sample gas feed unit is designed for continuous dosed feeding of

sample gas.

The SCC-F sample gas feed unit must not be used

for feeding mixtures of gas/air or gas/ oxygen that are capable of ignition during

normal service,

for feeding flammable gas, which can combine with air or oxygen to form an

ignition-capable mixture, or

in a potentially explosive atmosphere or in hazardous areas.

Standard model The sample gas feed unit is intended for installation in non-hazardous areas. It

complies with EN 61010 Part 1 “Safety requirements for electrical equipment for

measurement, control and laboratory use” and with standards CAN/CSA-C22.2

No. 61010-1-12 and UL Std. No. 61010-1 (3rd Edition).

Certificate no. 70010607.

Version for

Class I, Div. 2

The sample gas feed unit is certified to

Class 2258 02 Process Control Equipment – For Hazardous Locations – Certified

to Canadian Standards and

Class 2258 82 Process Control Equipment – For Hazardous Locations – Certified

to U.S. Standards

for use in hazardous areas Class I, Division 2, Groups A, B, C and D, temperature

code T4, ambient temperature max. +50 °C.

The approval includes the testing in accordance with the relevant Canadian CSA

and US American guidelines.

Certificate no. 1105720.

Details on the

rating plate

The details on the rating plate are applicable for the version of the sample gas feed

unit.