Mixing Learning System

4© Festo Didactic 696686

8.5 Level monitoring ___________________________________________________________________ 27

8.5.1 Capacitive proximity sensors ______________________________________________________ 28

8.5.2 Float switch ____________________________________________________________________ 28

8.5.3 Flow sensor, magnetic-inductive ___________________________________________________ 28

8.6 2-way ball valve with pneumatic quarter-turn actuator_____________________________________ 29

8.7 Compressed air supply ______________________________________________________________ 30

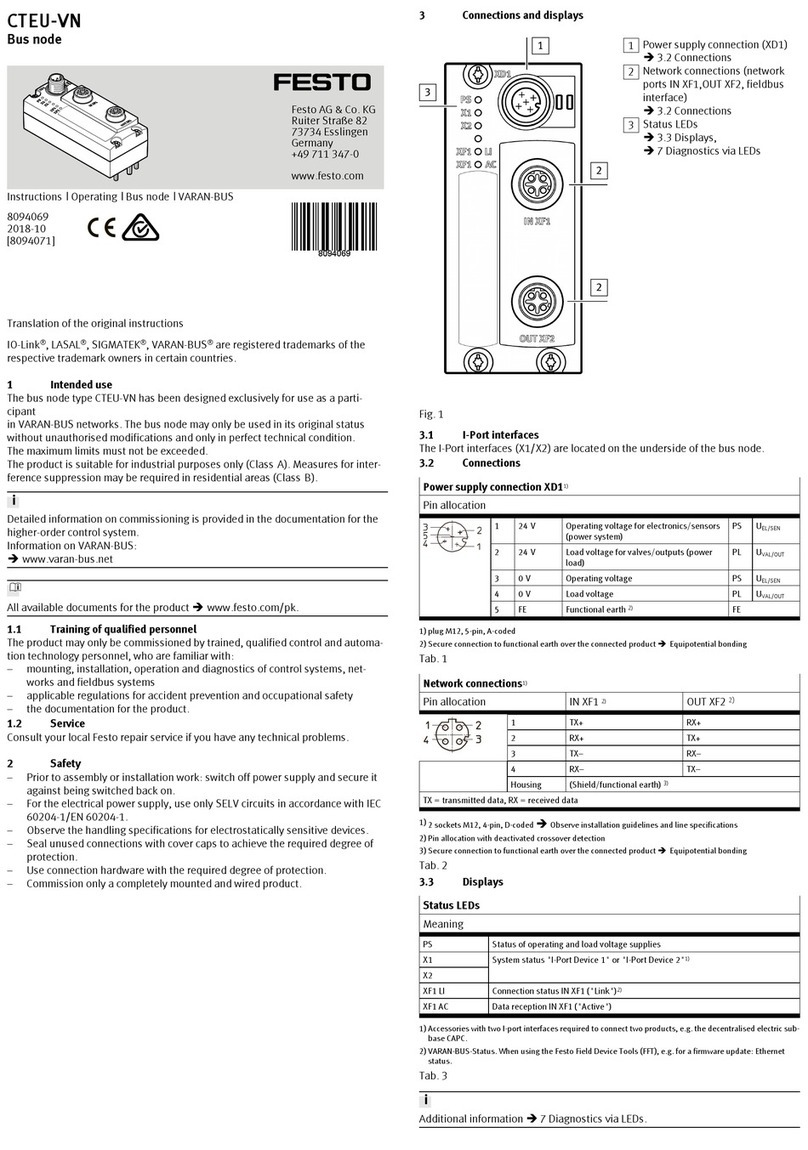

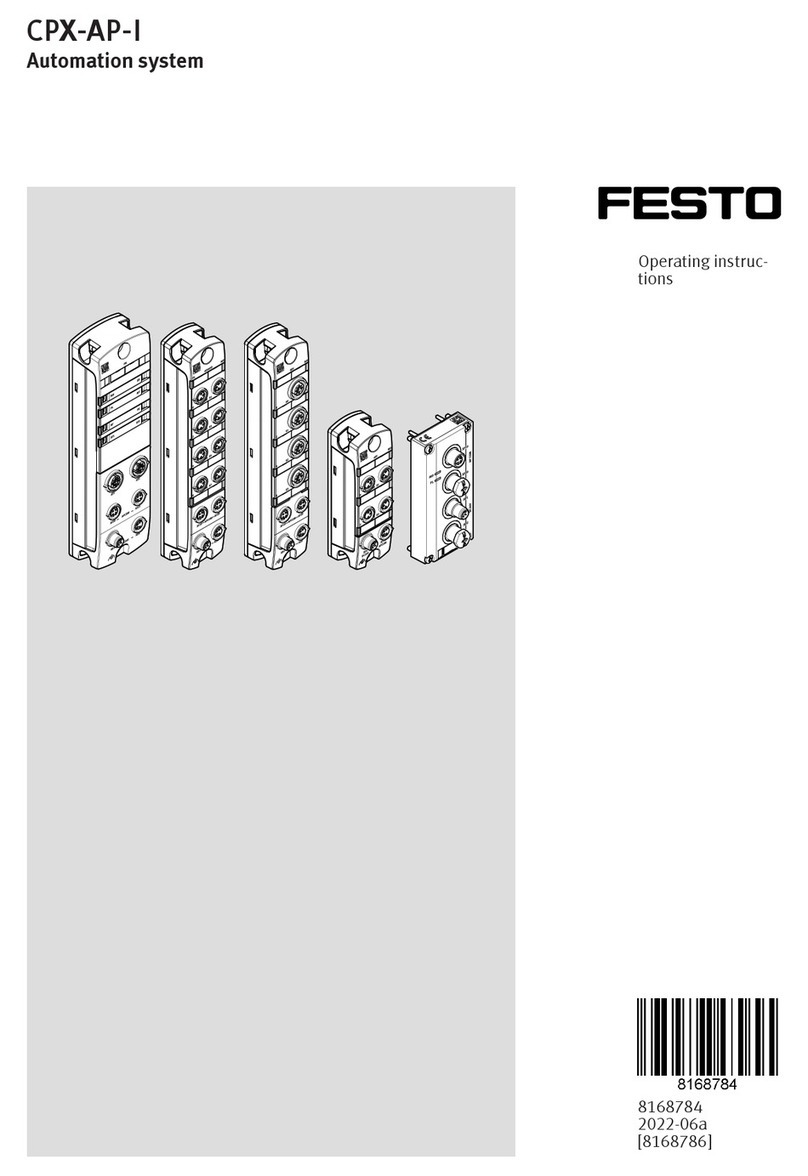

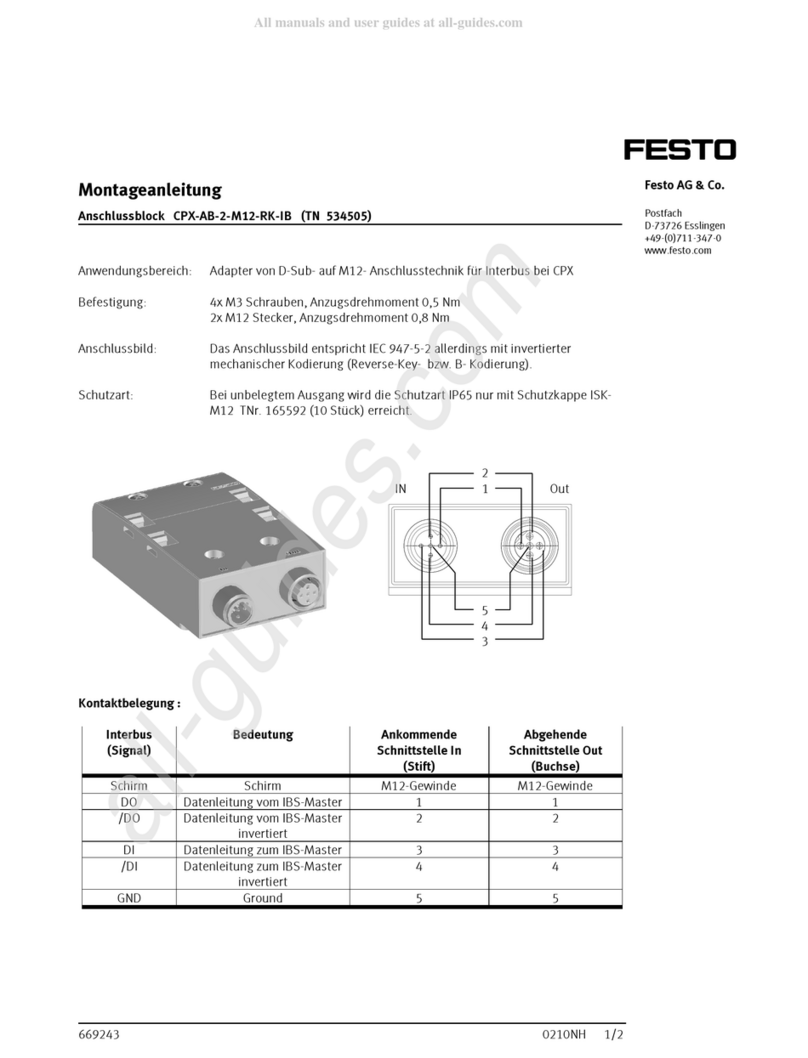

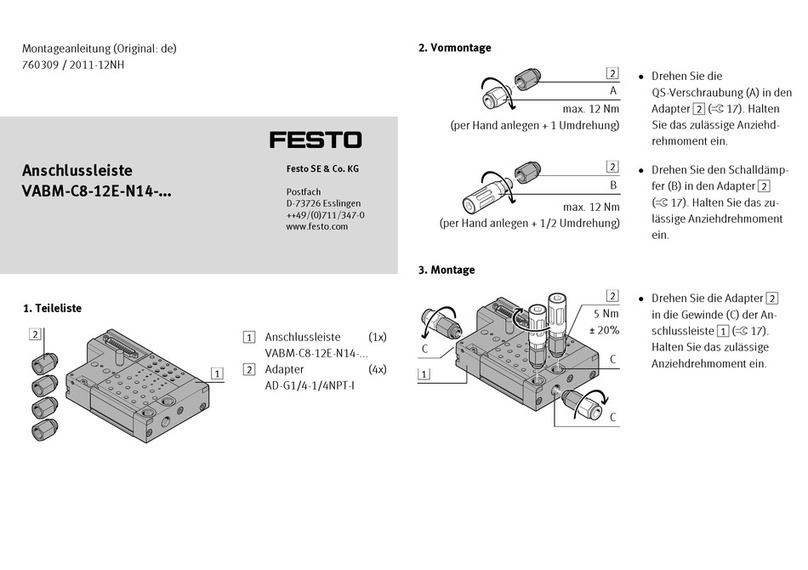

8.8 Electrical connection technology_______________________________________________________ 31

8.8.1 Connection board _______________________________________________________________ 31

8.8.2 Mounting frame_________________________________________________________________ 32

8.8.3 19″frame______________________________________________________________________ 33

8.9 PLC EduTrainer Universal S7-1512C ____________________________________________________ 34

8.10 Control console with operator unit TP700 Comfort _______________________________________ 35

8.11 EasyPort and FluidLab-PA closed-loop V5 ______________________________________________ 35

8.12 USB device server _________________________________________________________________ 36

8.13 Trolley 700 _______________________________________________________________________ 36

9 Function______________________________________________________________________________ 37

9.1 Function as individual station _________________________________________________________ 37

9.2 Operation as a downstream station ____________________________________________________ 37

10 Sequence description__________________________________________________________________ 38

10.1 Sequence description of the mixing process ____________________________________________ 38

10.2 Start-up prerequisites ______________________________________________________________ 38

10.2.1 Individual station ______________________________________________________________ 38

10.2.2 Station with downstream station__________________________________________________ 38

10.3 Initial position ____________________________________________________________________ 38

10.4 Sequence ________________________________________________________________________ 38

10.4.1 Automatic mode without downstream station _______________________________________ 39

10.4.2 Automatic mode with downstream station __________________________________________ 39

10.4.3 Manual mode _________________________________________________________________ 40

11 Commissioning _______________________________________________________________________ 41

11.1 Workstation ______________________________________________________________________ 42

11.2 Filling and emptying________________________________________________________________ 42

11.3 Power supply _____________________________________________________________________ 43

11.4 Compressed air supply _____________________________________________________________ 43

11.5 Actuation with PLC EduTrainer and control console ______________________________________ 43

11.5.1 Cable connections between station and EduTrainer PLC _______________________________ 43

11.5.2 Cable connections between control console and PLC EduTrainer ________________________ 45

11.5.3 Establish 1-bit communication connections _________________________________________ 45

11.5.4 Load sample project ____________________________________________________________ 46

11.5.5 Starting the sequence __________________________________________________________ 47

11.5.6 Operation on the control console with operator unit TP700 Comfort _____________________ 48