4-3

ENG

CYLINDER HEAD, CYLINDER AND PISTON

CYLINDER HEAD, CYLINDER AND PISTON

Job name/Part name

Cylinder head, Cylinder and piston

removal

Engine

Muffler/Gasket

Air shroud 2

Spark plug

Cylinder head/Cylinder head gasket

Cylinder

Piston pin clip

Piston pin/ Bearing

Piston

Piston ring set

Cylinder gasket

Remarks

Remove the parts in the order.

Refer to the “ENGINE REMOVAL” sec-

tion

Reverse the removal procedure for in-

stallation.

Order

1

2

3

4

5

6

7

8

9

10

Q’ty

1/1

1

1

1/1

1

2

1/1

1

1

1

4

5

6

7

10 1

2

3

26Nm(2.6 m.kg, 18.2 ft.lb)

T

R

.

.

14Nm(1.4 m.kg, 10 ft.lb)

T

R

.

.

9Nm(0.9 m.kg,6.5 ft.lb)

T

R

.

.

New

New

New

E

8

9

CYLINDER HEAD, CYLINDER AND PISTON

4-4

ENG

PISTON PIN AND PISTON REMOVAL

1. Remove:

8Piston pin clip 1

NOTE:

Before removing the piston pin clip, cover the

crankcase with a clean rag so you will not acci-

dentally drop the clip into the crankcase.

2. Remove:

8Piston pin 1

8Piston 2

8Piston pin bearing 3

cC

Do not use a hammer to drive the piston pin

out.

CYLINDER HEAD INSPECTION

1. Eliminate:

8Carbon deposits

Use a rounded scrapper 1.

2. Inspect:

8Cylinder head warpage

Out of specification∅Re-surface.

*************************************

Warpage measurement and re-surfacement

steps:

8Attach a straight edge 1and a thickness

gauge 2on the cylinder head.

8Measure the warpage limit.

Warpage limit:

0.03 mm(0.0012 in)

8If the warpage is out of specification, reface

the cylinder head.

NOTE:

Rotate the head severai tires to avoid remov-

ing too much material from one side.

*************************************

CYLINDER HEAD, CYLINDER, PISTON

2

1

EAS00007

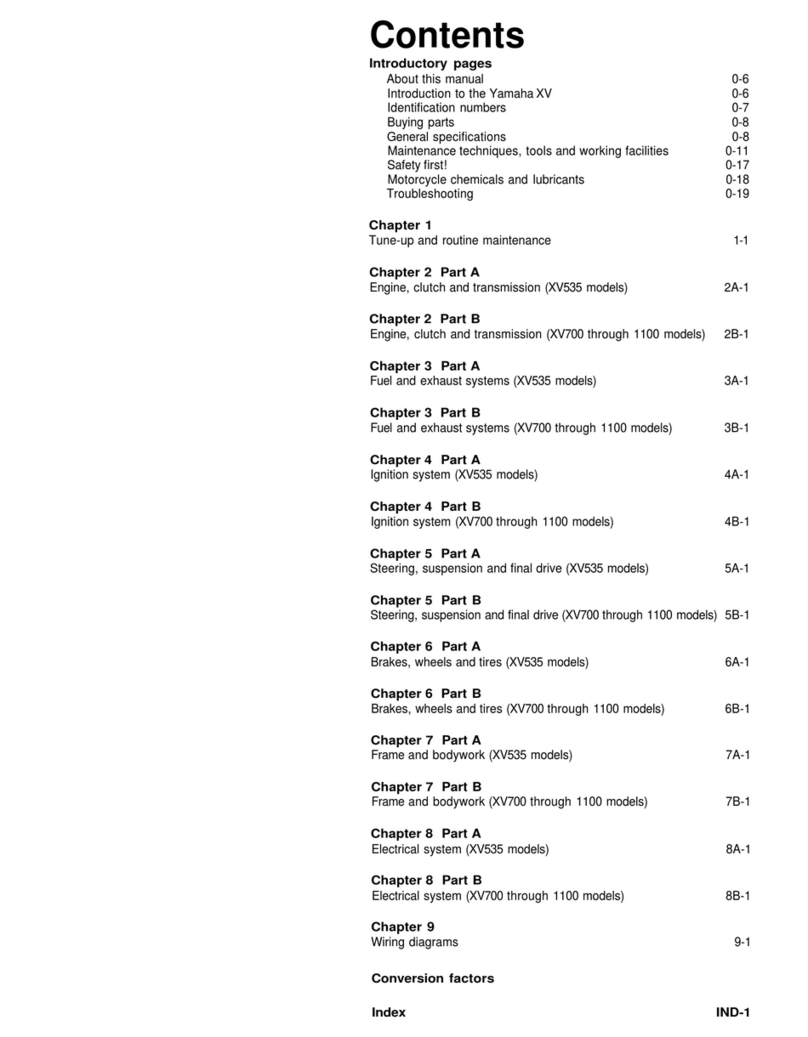

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive

explanations of all installation, removal, disassembly, assembly, repair and check procedures are

laid out with the individual steps in sequential order.

1The manual is divided into chapters. An abbreviation and symbol in the upper right corner of

each page indicate the current chapter.

Refer to “SYMBOLS”.

2Each chapter is divided into sections. The current section title is shown at the top of each page,

except in Chapter 3 (“PERIODIC CHECKS AND ADJUSTMENTS”), where the sub-section

title(s) appears.

3Sub-section titles appear in smaller print than the section title.

4To help identify parts and clarify procedure steps, there are exploded diagrams at the start of

each removal and disassembly section.

5Numbers are given in the order of the jobs in the exploded diagram. A circled number indicates

a disassembly step.

6Symbols indicate parts to be lubricated or replaced.

Refer to “SYMBOLS”.

7A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of

parts, notes in jobs, etc.

8Jobs requiring more information (such as special tools and technical data) are described se-

quentially.

8

4

5

7

1

3

26