SAFETY WHILE WORKING

1-3

E

GEN

INFO

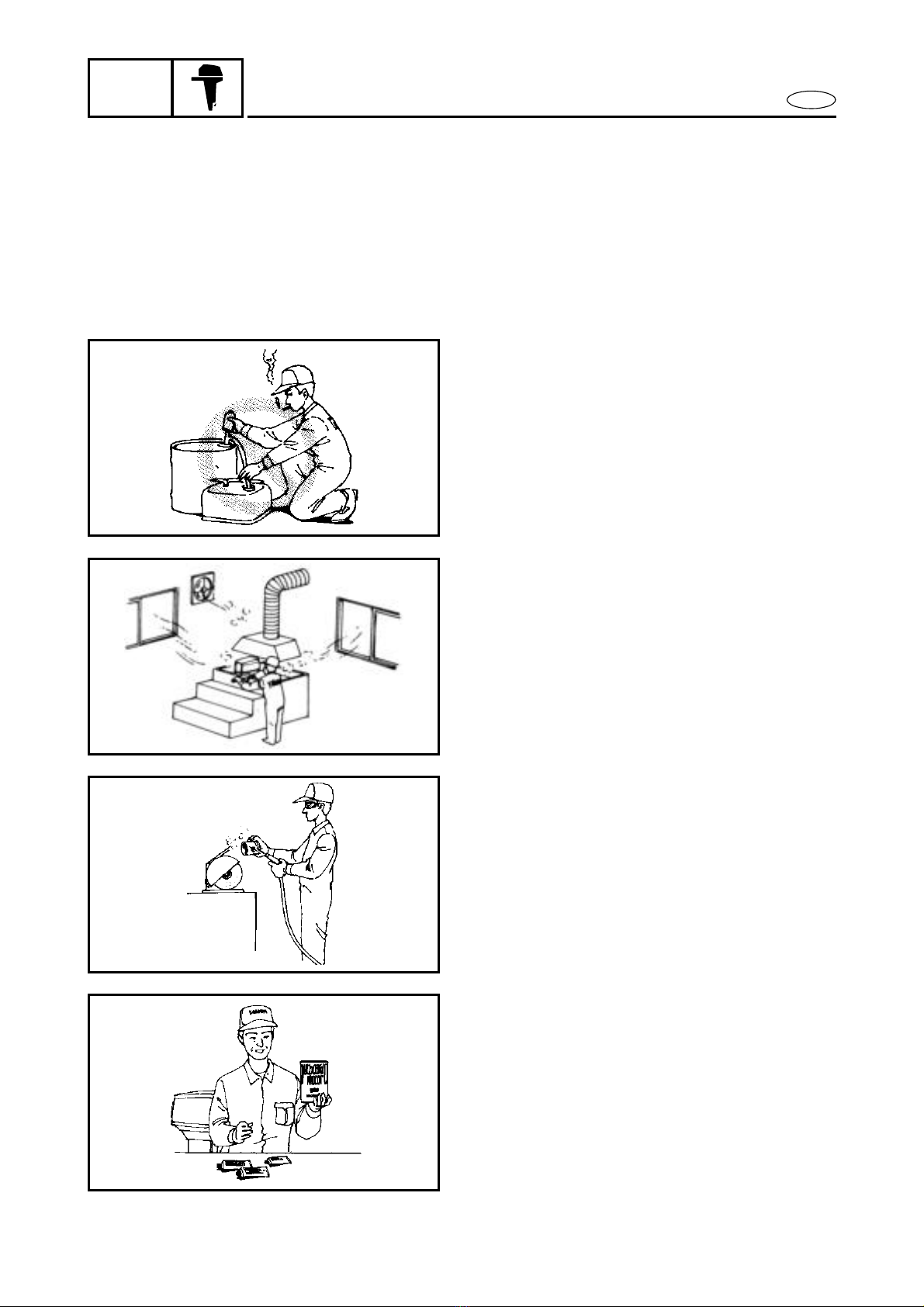

Under normal conditions or use, there

should be no hazards from the use of the

lubricants mentioned in this manual, but

safety is all-important, and by adopting

good safety practices, any risk is minimized.

A summary of the most important precau-

tions is as follows:

1. While working, maintain good stan-

dards of personal and industrial

hygiene.

2. Clothing which has become contami-

nated with lubricants should be

changed as soon as practicable, and

laundered before further use.

3. Avoid skin contact with lubricants; do

not, for example, place a soiled wiping-

rag in your pocket.

4. Hands and any other part of the body

which have been in contact with lubri-

cants or lubricant-contaminated cloth-

ing, should be thoroughly washed with

hot water and soap as soon as practica-

ble.

5. To protect the skin, the application of a

suitable barrier cream to the hands

before working, is recommended.

6. A supply of clean lint-free cloths should

be available for wiping purposes.

GOOD WORKING PRACTICES

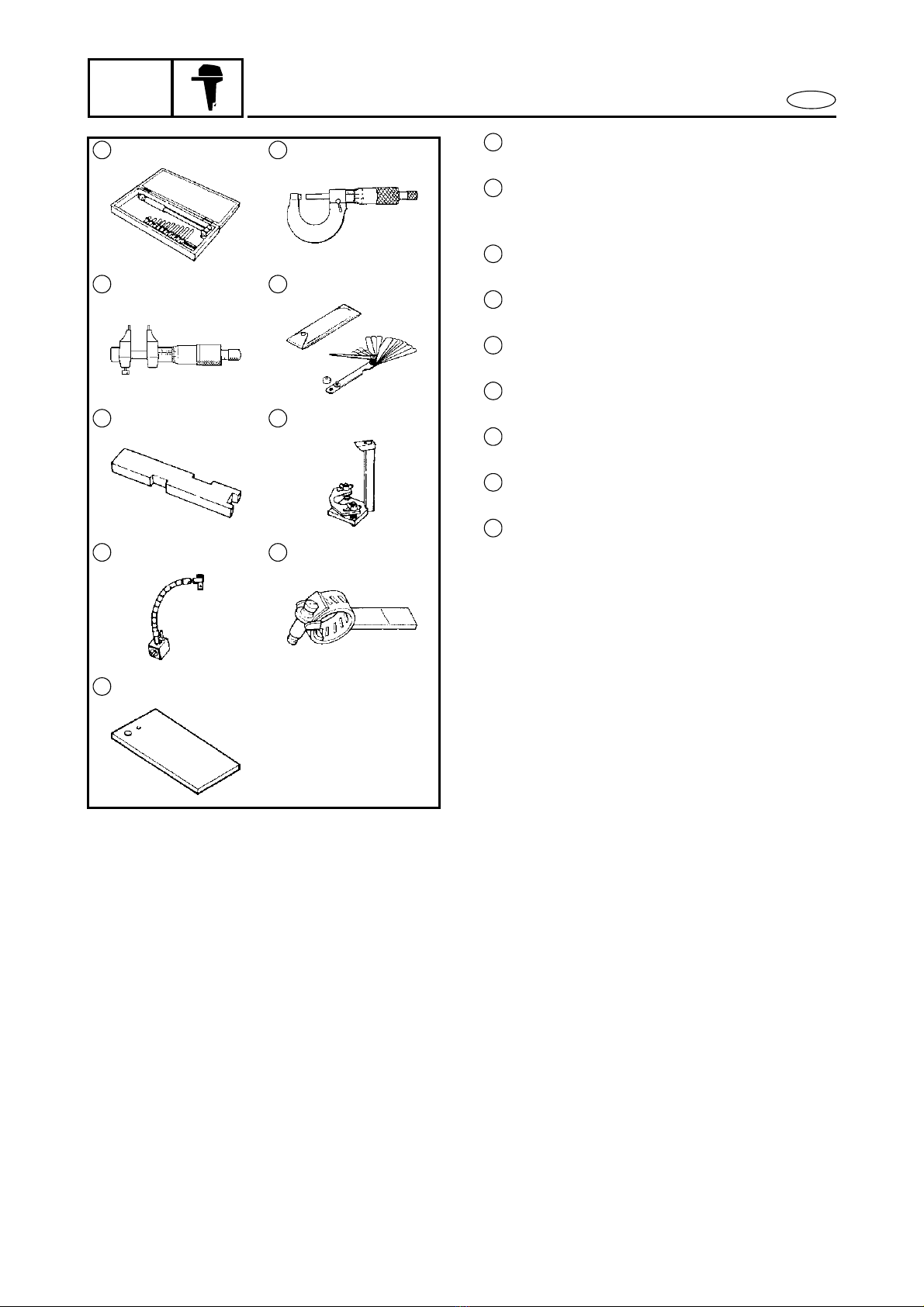

1. The right tools

Use the recommended special tools to

protect parts from damage. Use the

right tool in the right manner - do not

improvise.

2. Tightening torque

Follow the tightening torque instruc-

tions. When tightening bolts, nuts and

screws, tighten the large sizes first, and

tighten inner-positioned fixings before

outer-positioned ones.