2

Introduction

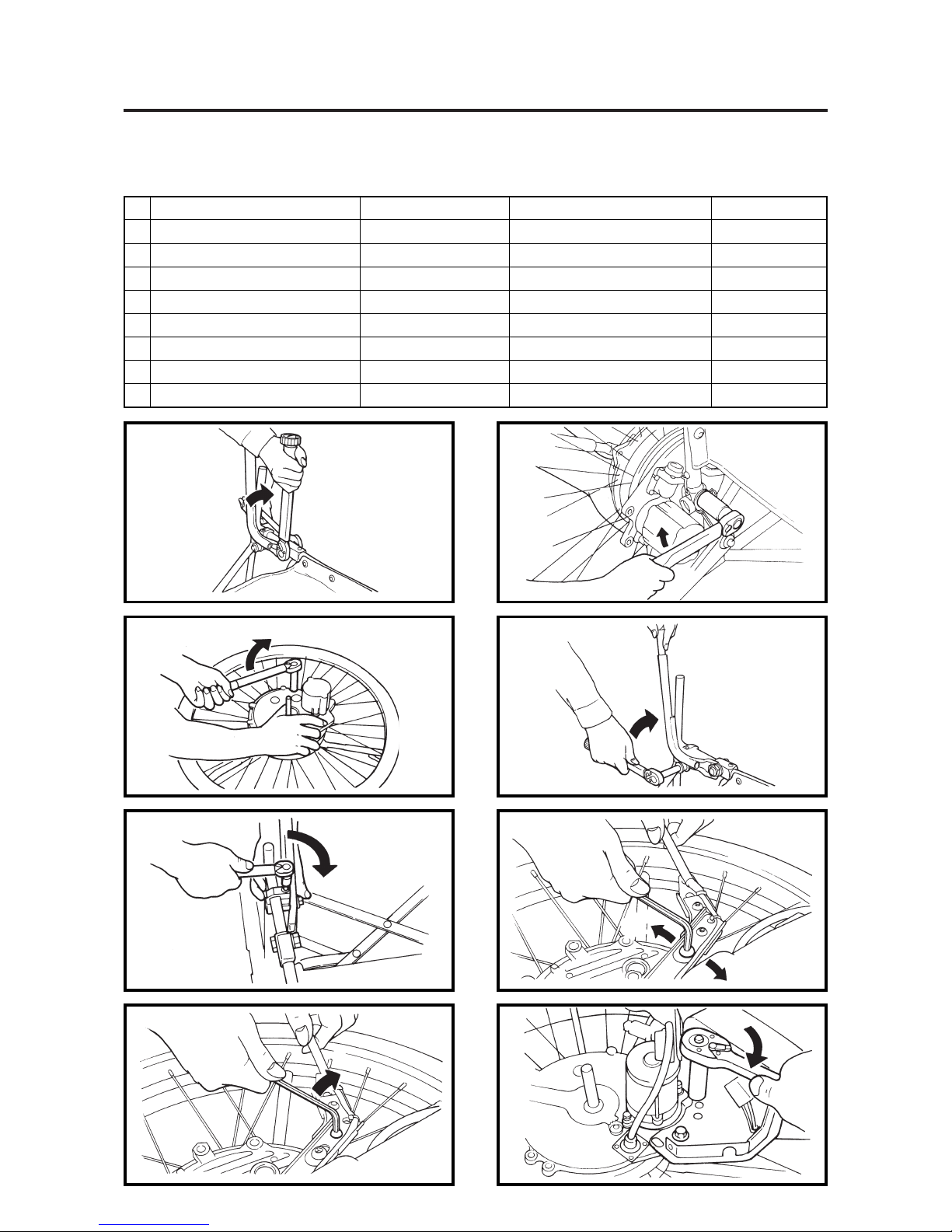

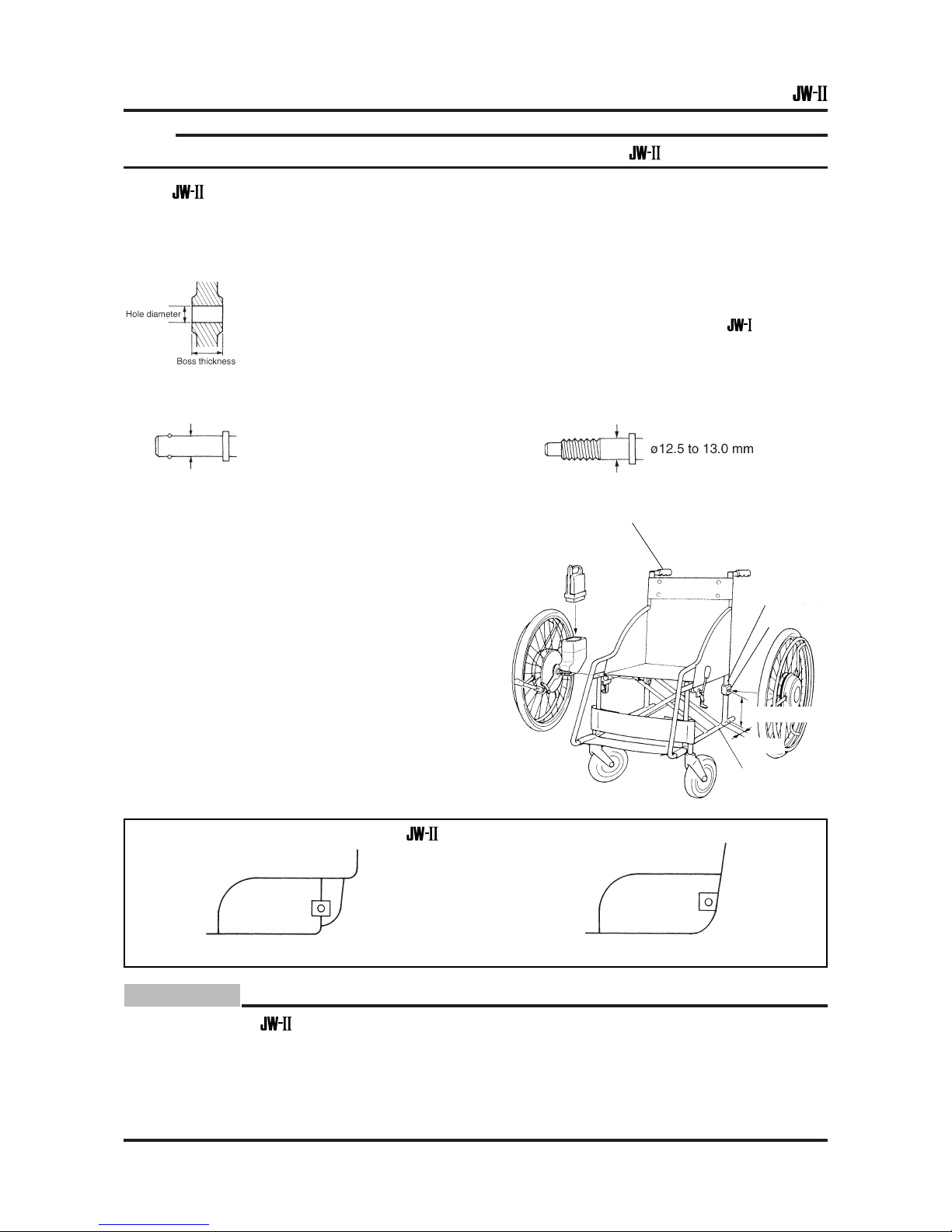

•Guidelines for selecting type Aor Bor C

1. Atype is suitable for those who are capable of grasping the hand rims (such as paraplegics) and

have enough strength to travel easily up a slope of about 4°(inclination of a slope inside a build-

ing). Users with this much strength may not like the way uphill travel feels with the type Bmodel,

because the hand rims feel loosely mounted.

2. Btype is suitable for those who are incapable of grasping the hand rims (such as quadriplegics)

and have difficulty traveling up a slope of about 4°manually by themselves. Slopes will become

easier if climbed slowly. If these users use the Atype, they will not be able to use the power assist

function effectively, since they are incapable of pushing the hand rims sufficiently.

✽If the user tests the type Bmodel and feels that there is a sense of scraping bottom when the

hand rims are turned slightly forcefully, the type Amodel is more suitable. The type Amodel

should be test-ridden before the final specifications are decided.

3. The Ctype is designed for persons who are able to operate one hand rim with one hand and to

steer with one foot (such as hemiplegia). (Steering cannot be done by the hand rim alone.)

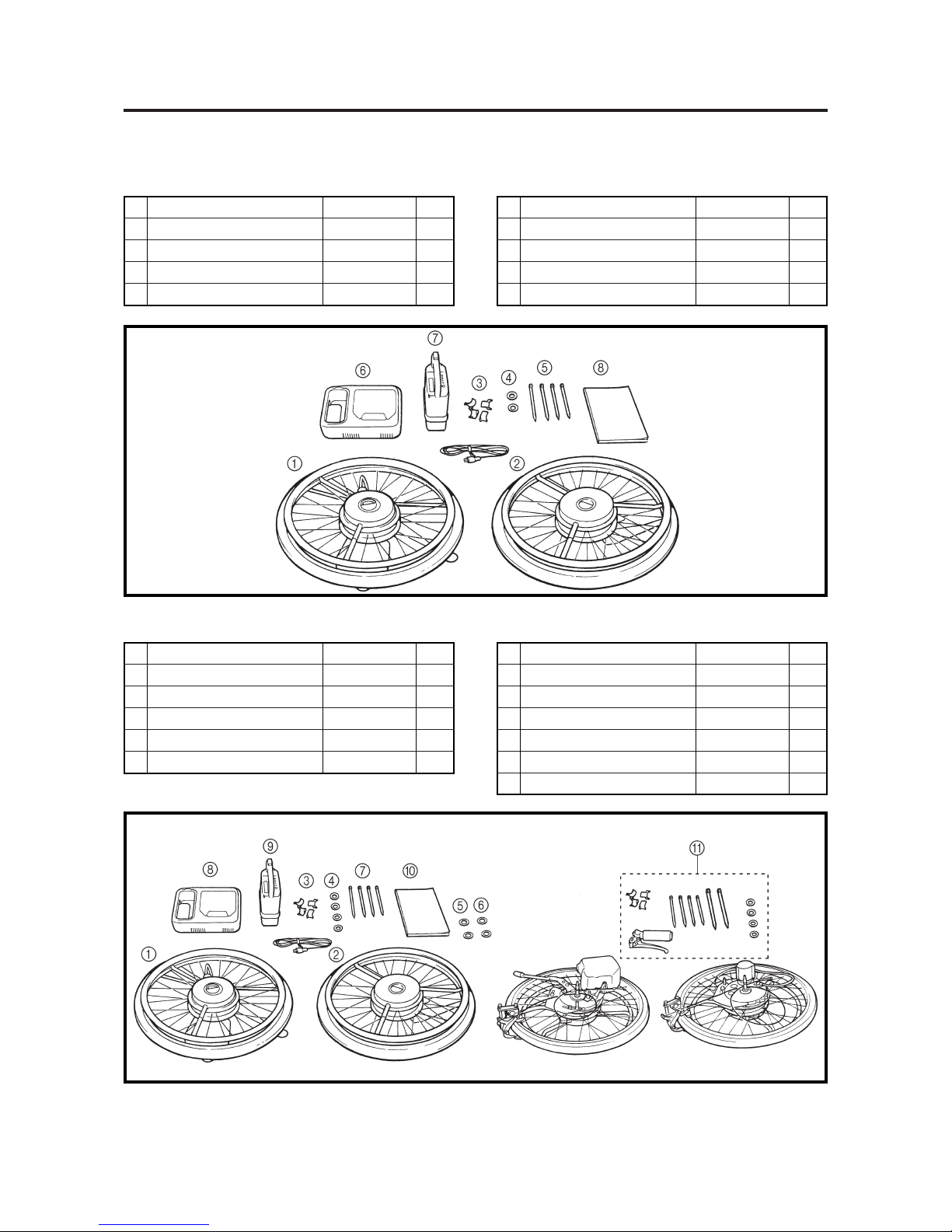

Model Variation/

Principal Specifications

XA41 (catalogue indication: A type)

XA42 (catalogue indication: B type)

XA43 (catalogue indication: C type)

A and B types 15.8 Kg

C type 17.2 Kg

22×1 3/8WO (tire outer diameter: 570 ± 3 mm)

24×1 3/8WO (tire outer diameter: 608 ± 3 mm)

Direct current brush type motor

24 V

90 W×2 (Left wheel ×1, right wheel ×1)

A and B types Approx. 15 km

C type Approx. 10 km

(For continuous travel on a level surface at 5 km/h,

the C type is 3.5 km/h.)

A and B types 0 to 6 km/h

C type 0 to 4 km/h

Microcomputer control

Belt + gear type (rear wheel direct drive)

Right and left hand rim steering. (C: Foot)

Brake assist + manual wheelchair brake

Nickel-Hydrogen battery (fast-charging type)

Two 1.2 V ×20-cell batteries connected in series, 24 V

6.7 Ah (5-hour ratio)

2.9 Kg

JWC-2

AC 100 ~ 240 V, multi-input

50/60 Hz

Fast 2.6 A trickle 100 mA

Forced air-cool

0 to 40°C (battery temperature)

2.5 to 3.0 h

30A blade-type micro-fuse

Competition silver

Circuit silver

Model Type

Unit Weight

Tire Size (2 types): nominal diameter of 22 inches

nominal diameter of 24 inches

Power Assist Unit: Model Type

Rated Voltage

Rated Output

Travel Distance After Single Charge

Range of Assisted Speeds

Control

Drive

Steering

Braking

Battery: Model Type

Nominal Voltage

Nominal Capacity

Weight

Charger: Model Type

Input Voltage

Input Frequency

Charging Current

Cooling Method

Range of Temperature at Start of Charging

Charging Time

Overcurrent Interception

Coloring: Cap, Wheel and Hub Case, Transmission

Principal Specifications