5

3.Pressure of measurement and connection of piping

a) Measurement of positive pressure

Connect the tube to the high pressure side piping connector (indicated by red color or letter H).

The lower pressure port (blue or L) should opened to atmosphere, but do not remove the piping

connector.

b) Measurement of negative pressure

Connect the tube to the low pressure side piping connector (blue or L). The high pressure port (red or

H) should be opened to atmosphere, but do not remove the piping connector.

c) Measurement of differential pressure

Connect the tube from the high pressure piping connector to the high pressure port (red or H) and from

the low pressure piping connector to the low pressure port (blue or L).

△

!

Caution

Measurement of single pressure using an instrument with zero point center range.

Connect the tube to the high pressure side piping connector (red or H). In this case again,

leave the piping connector attached to the low pressure side, which is opened to atmosphere.

The single pressure is as displayed on a zero point center scale (+-).

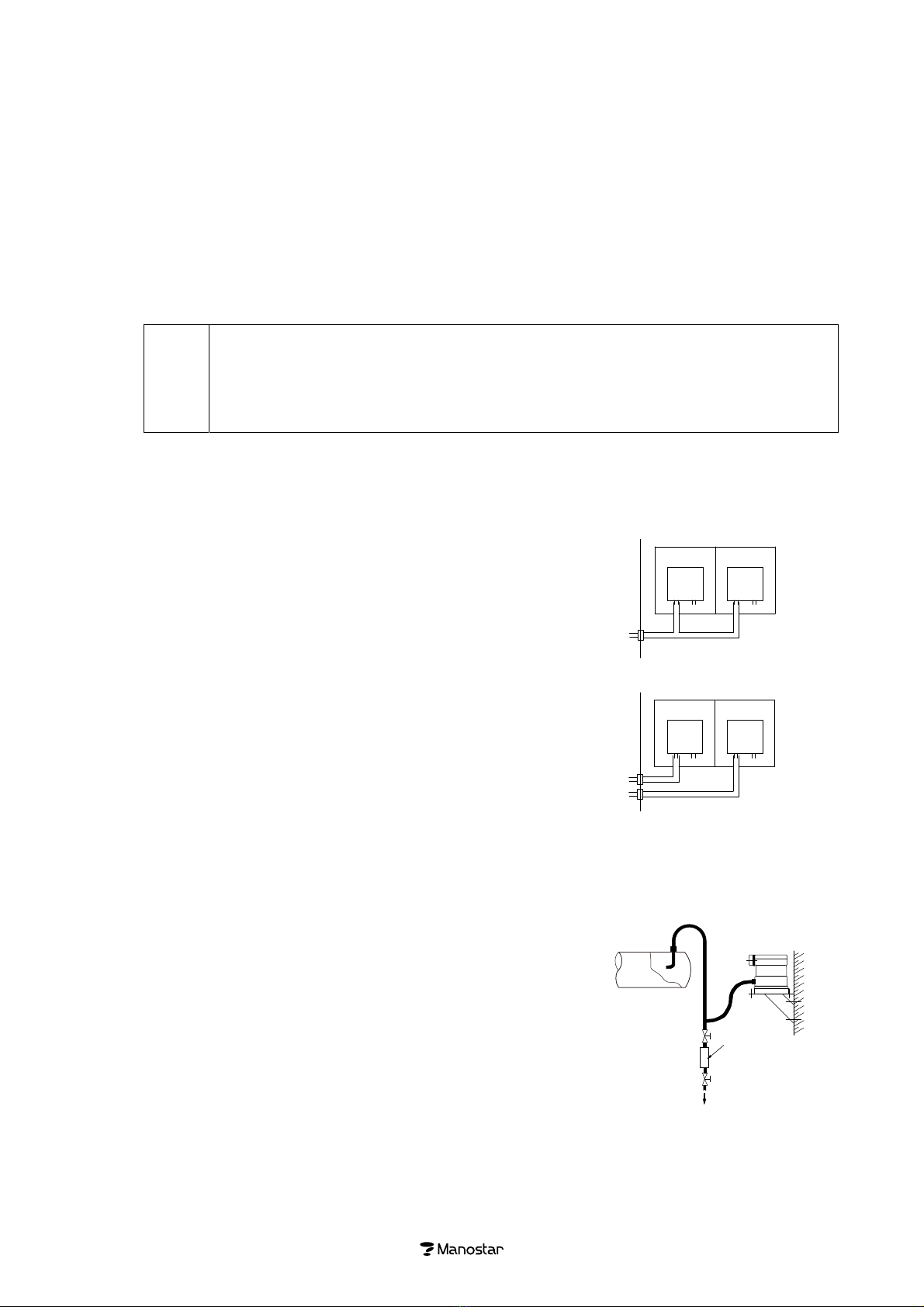

4.Caution of piping

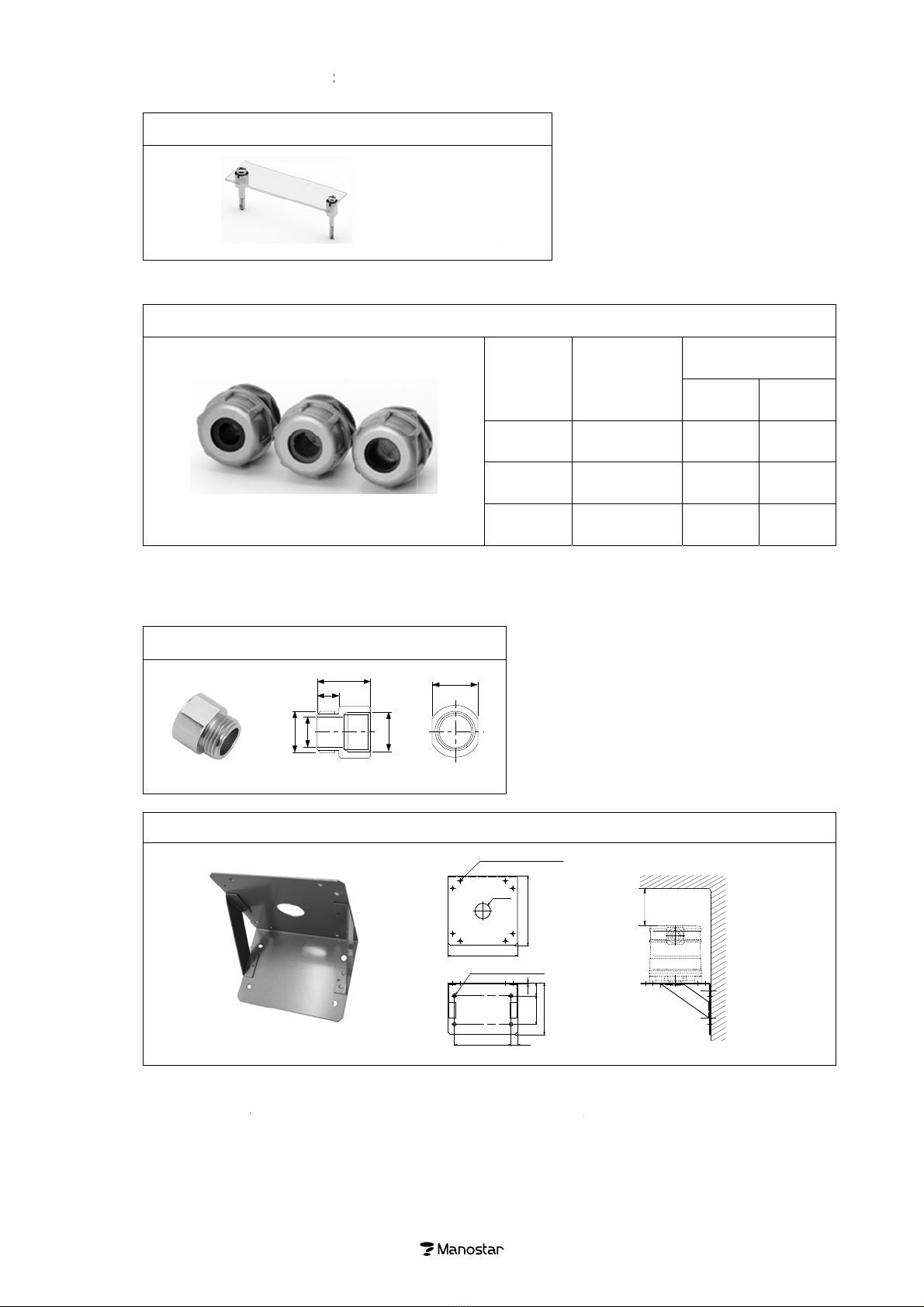

・Prohibition of common piping

Piping each of pressure detectors and pressure receiving

instruments tube exclusively dedicated for it, and do not

connect the piping commonly with the adjacent system as

shown in the right figure.

Common piping causes measurement error because the

pressure of each system interferes.

・Prevention of clogged piping due to drain

If drain remains within the line, it causes measurement error.

Be sure to install the pressure receiving instrument above the

pressure outlet port of the pressure detector and arrange the

line so that the drain water should not remain in the slack

piping.

If the arrangement mentioned above in not possible, install a

drain tank within the line as shown in the right figure and clean

it once in a while.

After the cleaning of the tank, check that the air tightness is

fully kept.

・Measurement of high temperature gases

In the pressure measurement of high temperature gas, use the

pressure detector (pitot tube) made of the heat-proof metal

(such as stainless steel), and connect it with the pressure

receiving instrument through a metal tube which is long

enough to cool down the high temperature gas.

・Errors caused by long distance piping

The speed of response is delayed when the product is used for

remote monitoring.

In such application, the I.D. of the connection tube should be

as large as possible.

If the piping conditions of the high and low pressure side are

significantly different, the difference in the piping resistance

between high and low pressure side causes the difference in

pressure transmission time, and the measurement becomes

inaccurate.

Independent piping○

Passa

ewa

Passa

ewa

Room BRoom A

Room BRoom A

EMT1EMT1

EMT1EMT1

Common piping×

Drain

Drain

tank