5

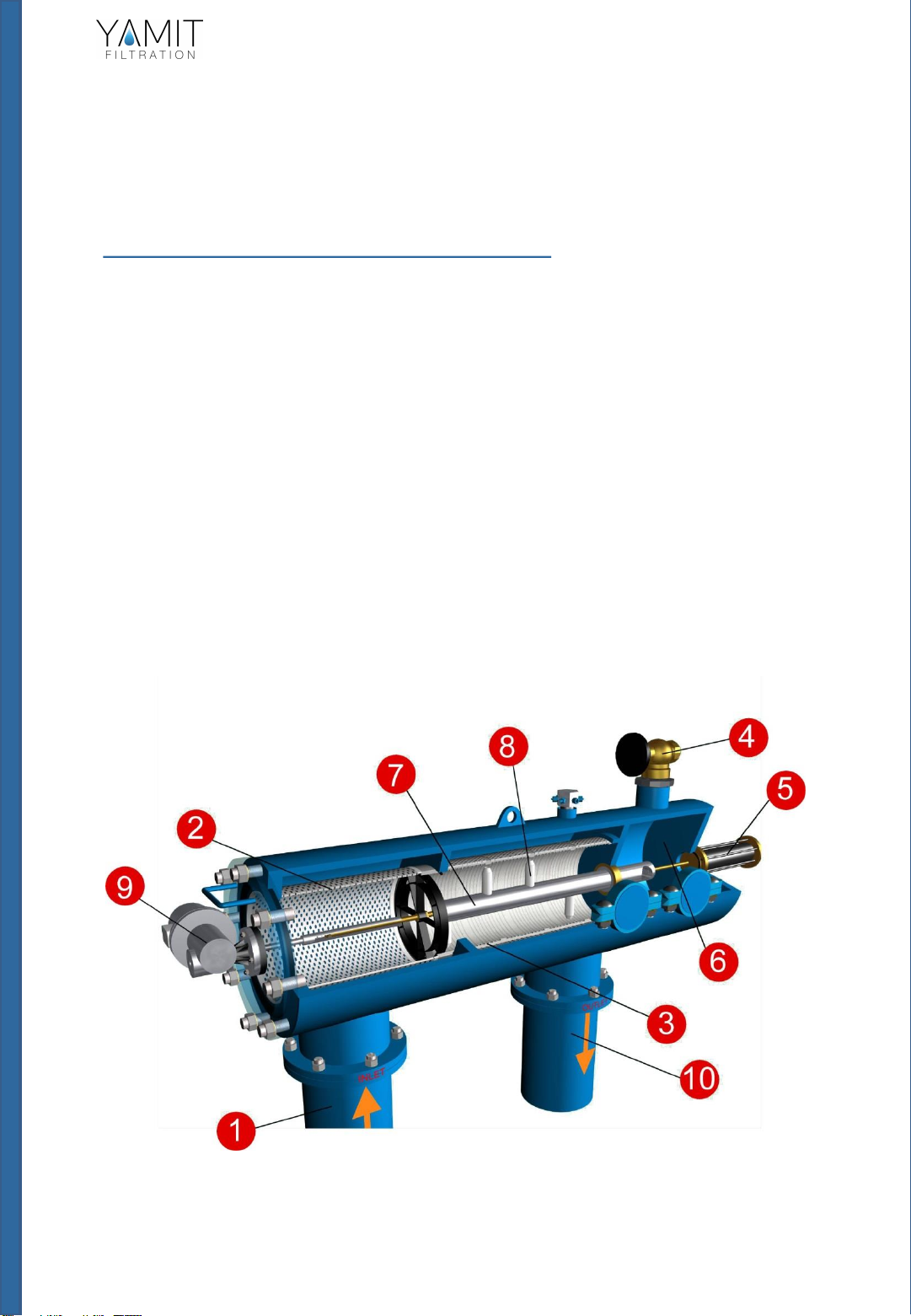

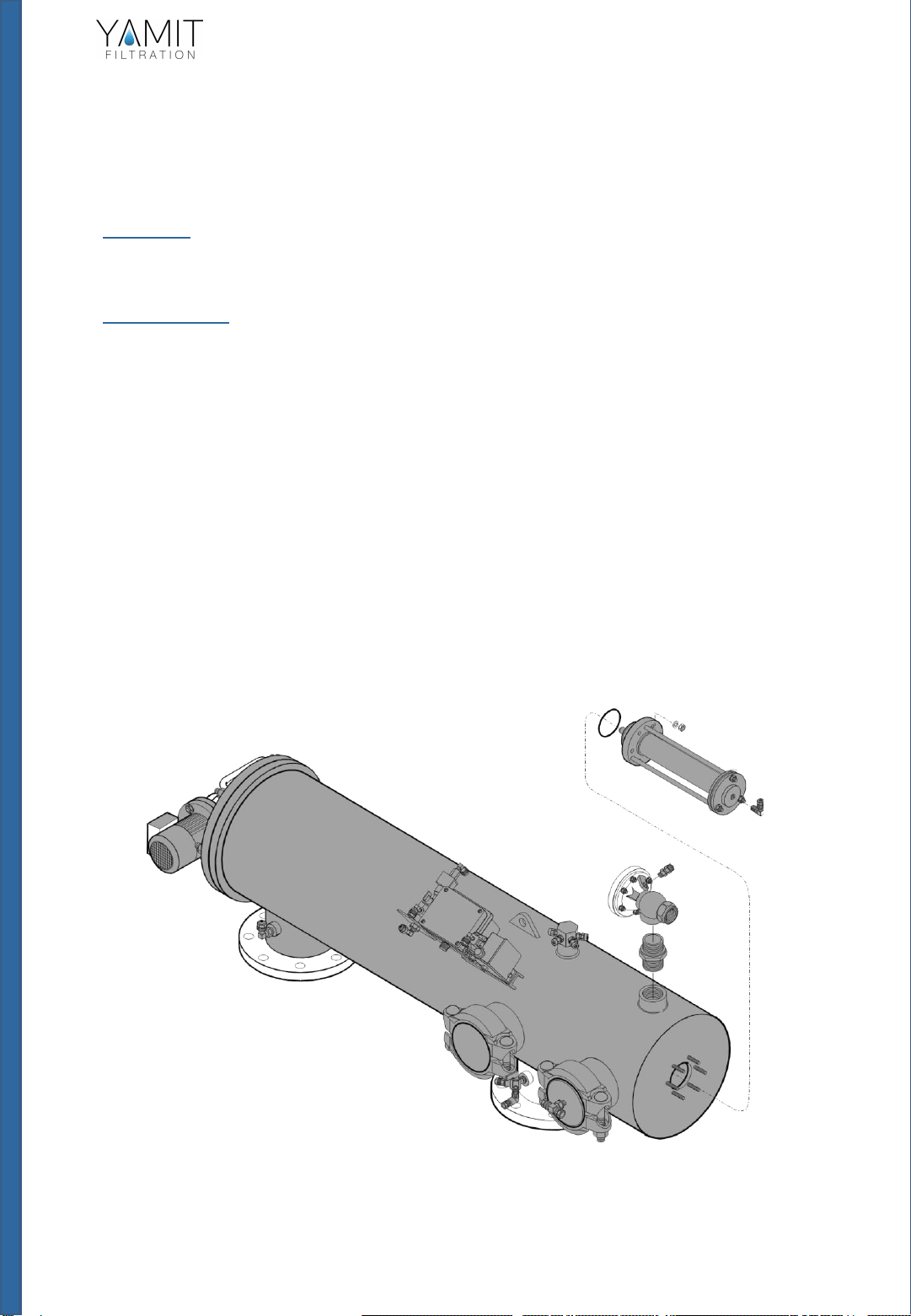

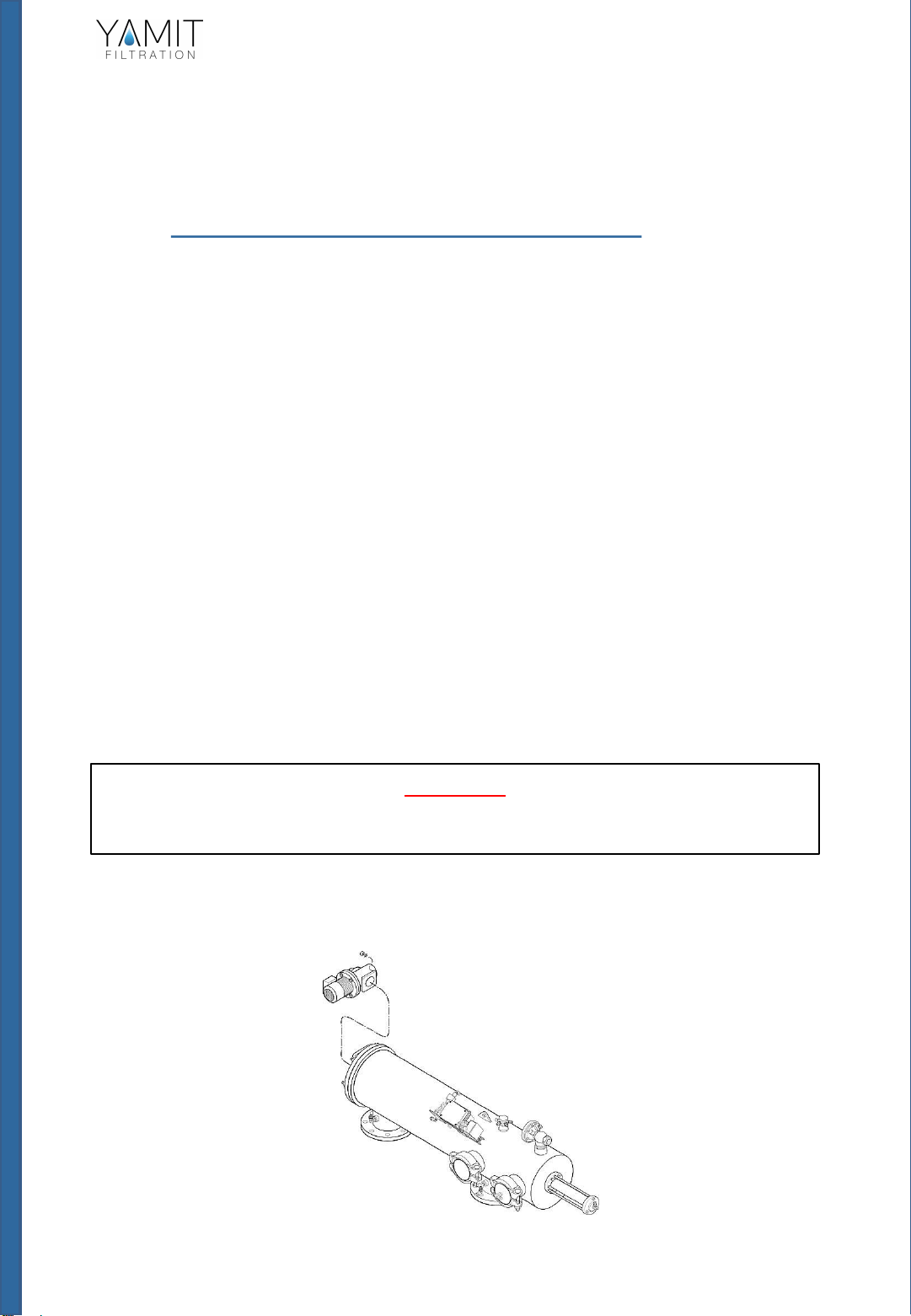

Filter Operation General Description

Filtration

Water enters the filter through the “Inlet” (1) and passes through the coarse

screen (2) that functions as a “first stop” for rough particles. Water then

reaches the fine screen (3), which further purifies the flow by separating

smaller particles from the water. As more water flows through, impurities

build up on the fine screen. As impurities on the screen accumulate, a

pressure imbalance is built up between the internal section of the fine screen

(3) and its external section.

Cleaning Process

When the difference in pressure (ΔP) reaches the preset value on the

differential pressure indicator, Or when the preset time in the controller

arrives, a series of events is triggered while water continues to flow to the

system units. The controller transmits a signal for a 15 second flushing cycle.

The solenoid opens the flushing valve (4), and release the pressure from the

hydraulic piston (5). Water flows outside from the flushing valve (4). Pressure

in the hydraulic chamber (6) and the dirt collector (7) is significantly lowered

resulting in a suction process via the suction nozzles (8) to the dirt collector (7)

and from there to the hydraulic chamber (6) through the flushing valve (4)

outside. The electric motor (9) simultaneously rotates the dirt collector (7)

around its axis. The pressure is released from the piston (5) and the high

pressure inside the filter causes linear movement of the dirt collector. The

combination of the linear movement and rotation efficiently cleans the entire

internal screen (3) surface.

At the end of the 15 second cycle the flushing valve (4) closes and the

operation of the electric motor (9) is stopped. The increased water pressure

returns the hydraulic piston (5) to its initial position. The filter is now ready for

the next cycle, with clean and filtered water flowing through the “Outlet” (10).

The 15 second flushing cycle resumes operation whenever the difference in

pressure reaches the preset pressure value set on the differential pressure

indicator. Or when the preset time in the controller is triggered on. If the

pressure difference remains unchanged after one cycle, another cycle will start

after a delay of 10 seconds

AF9800