3

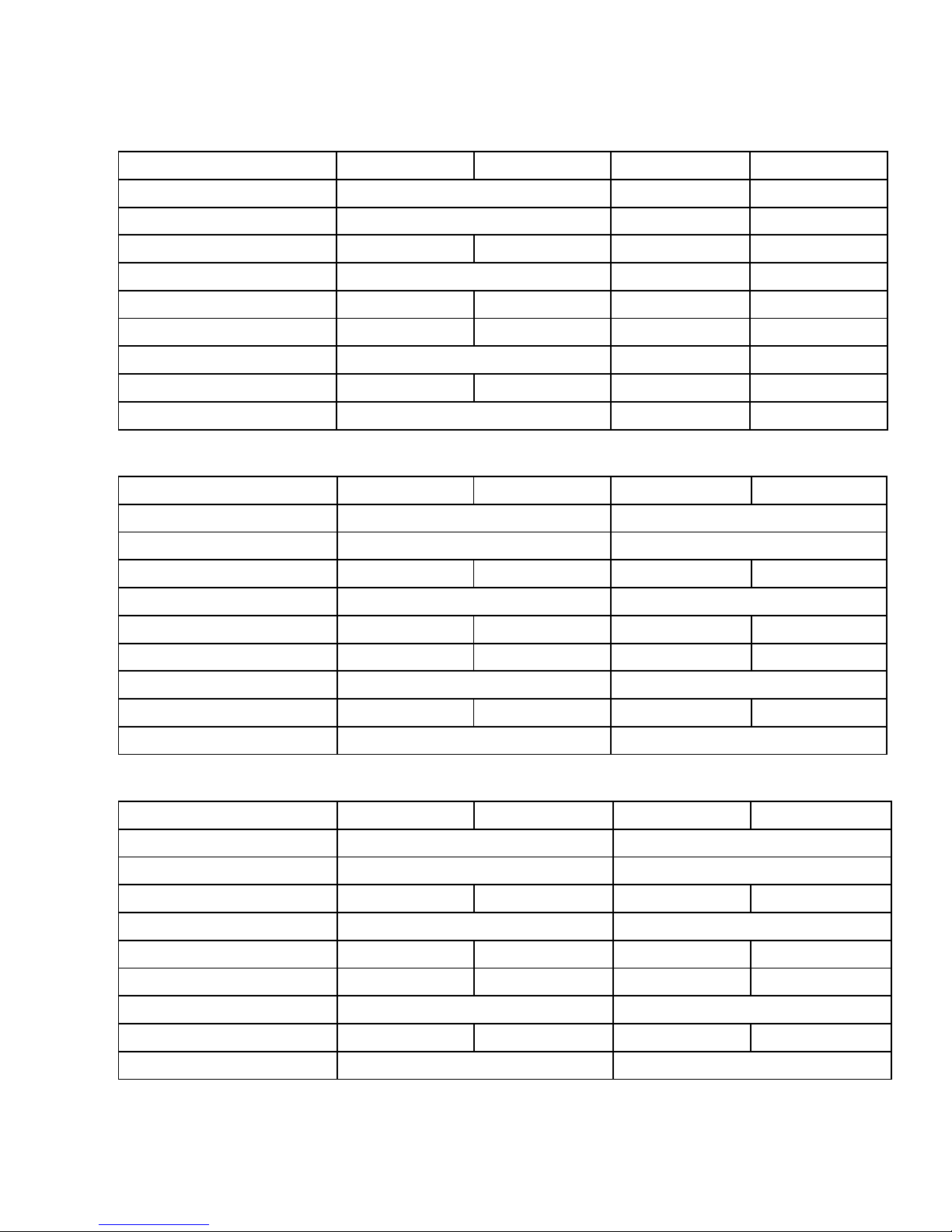

Model & Parameter List

Model FD2.1-200-8L FD2.1-200-8H FD2.5-300-8L FD2.5-300-8H

Rated power(W) 200W 300W 300W

Rated voltage (V) 24 24V 24V

Rotor diameter(M) 2.2 1.8 2.5 2.0

Start-up wind speed(m/s) 3 2.5 2.5

Rated wind speed(m/s)6 12 7 12

Security wind speed(m/s) 16 35 16 35

Rated rotating rate(r/m)450 400 400

Blade material glass fiber glass fiber glass fiber Glass fiber

Blade quantity 3 3 3

Model FD2.7-500-10L FD2.7-500-10H FD3.0-1000-10L FD3.0-1000-10H

Rated power(W) 500W 1KW

Rated voltage (V) 24 48

Rotor diameter(M) 2.5 2.1 2.7 2.3

Start-up wind speed(m/s) 2 2

Rated wind speed(m/s)8 12 9 12

Security wind speed(m/s) 16 35 16 35

Rated rotating rate(r/m)400 400

Blade material glass fiber glass fiber glass fiber glass fiber

Blade quantity 3 3

Model FD3.6-2000-10L FD3.6-2000-10H FD5.0-3000-16L FD5.0-3000-16H

Rated power(W) 2000W 3000W

Rated voltage (V) 120 240

Rotor diameter(M) 3.2 2.5 4.5 3.6

Start-up wind speed(m/s) 2 2

Rated wind speed(m/s)9 12 10 12

Security wind speed(m/s) 16 35 25 45

Rated rotating rate(r/m)400 220

Blade material glass fiber glass fiber glass fiber glass fiber

Blade quantity 3 3