CONTENTS

1. General ............................................................................................................................ 1

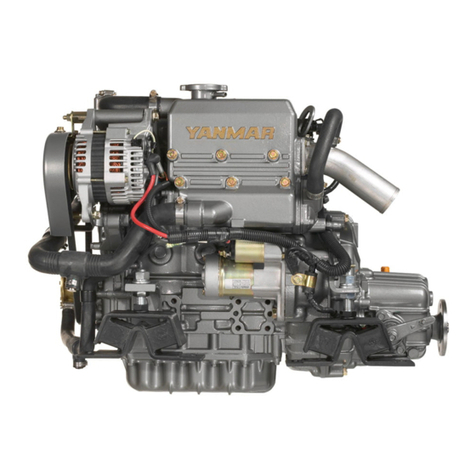

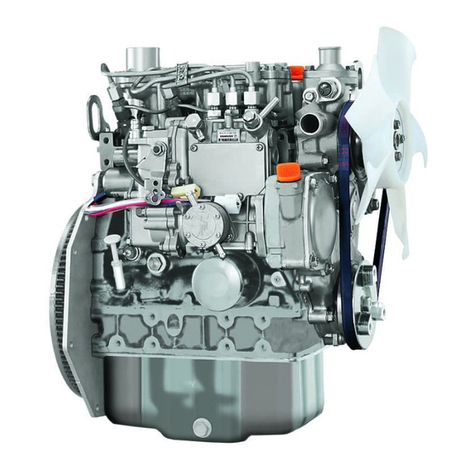

1.1 Exterior views ...........................................................................................................................1

1.2 Specifications ...........................................................................................................................2

1.3 Fuel oil, lubricating oil and cooling water .................................................................................4

1.3.1 Fuel oil .............................................................................................................................................. 4

1.3.2 Lubricating oil.................................................................................................................................... 4

1.3.3 Cooling water .................................................................................................................................... 5

1.4 Engine outline ..........................................................................................................................6

1.5 Piping diagrams .....................................................................................................................16

1.6 Exhaust gas emission regulation ...........................................................................................22

1.6.1 Engine identification (3JH4E).......................................................................................................... 22

1.6.2 Emission Standard.......................................................................................................................... 23

1.6.3 Guarantee conditions for emission standard .................................................................................. 23

2. Inspection and Adjustment ............................................................................................ 25

2.1 Periodic maintenance schedule .............................................................................................25

2.2 Periodic inspection and maintenance procedure ...................................................................27

2.2.1 Check before starting...................................................................................................................... 27

2.2.2 Inspection after initial 50 hours or one month operation ................................................................. 30

2.2.3 Inspection every 50 hours or monthly ............................................................................................. 35

2.2.4 Inspection every 250 hours or one year.......................................................................................... 39

2.2.5 Inspection every 1,000 hours or four years..................................................................................... 44

2.3 Adjusting the no-load maximum or minimum speed ..............................................................51

2.4 Sensor inspection ...................................................................................................................51

2.4.1 Oil pressure switch.......................................................................................................................... 51

2.4.2 Thermo switch................................................................................................................................. 51

2.5 Thermostat inspection ............................................................................................................52

2.6 Adjusting operation ................................................................................................................53

2.6.1 Preliminary precautions .................................................................................................................. 53

2.6.2 Adjusting operation procedure ........................................................................................................ 53

2.6.3 Check points and precautions during running................................................................................. 54

2.7 Long storage ..........................................................................................................................55

3. Troubleshooting .............................................................................................................56

3.1 Preparation before troubleshooting ........................................................................................56

3.2 Quick reference chart for troubleshooting ..............................................................................57

3.3 Troubleshooting (Concerning engine and fuel injection equipment) ......................................66

3.4 Troubleshooting by measuring compression pressure ..........................................................69