4

The tool is the best electrical tester for reducing diagnostic time in

all 6 to 30-volt vehicle electrical systems. After a simple hook-up

of the tool to the vehicle’s battery, you can:

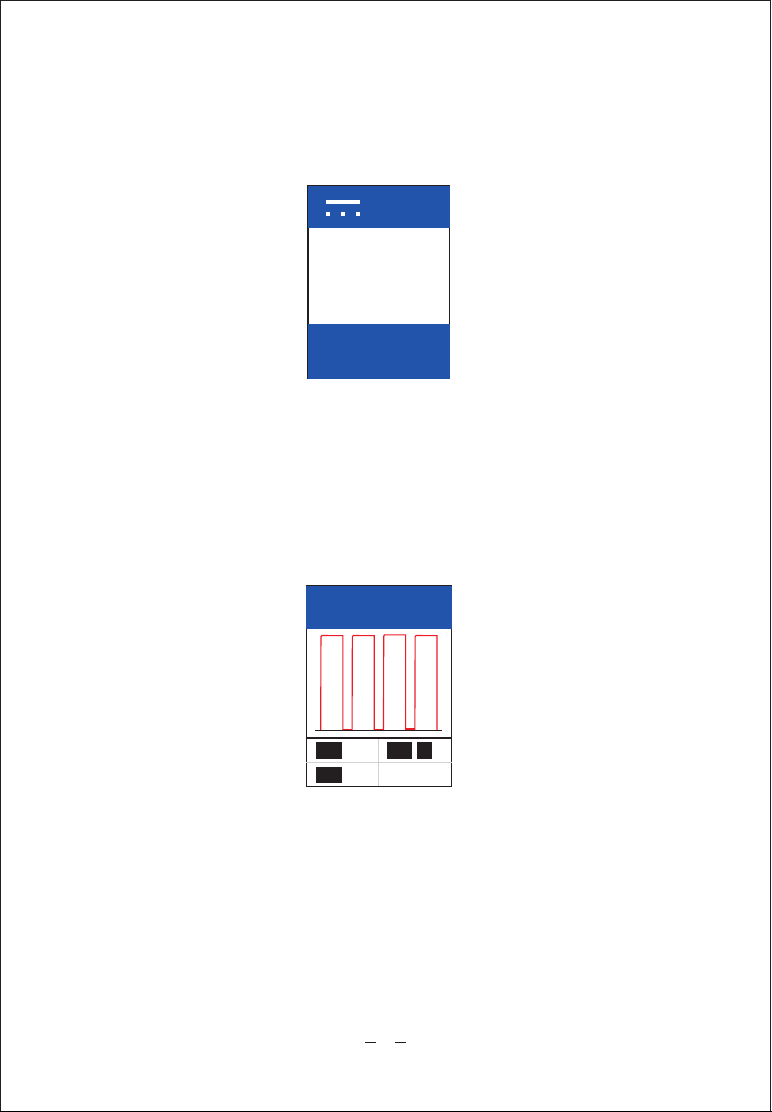

The tool is powered via the vehicle battery. Connect the RED battery

clamp to the POSITIVE terminal of the vehicle’s battery, and the

BLACK clamp to the NEGATIVE terminal. When the tool is first

connected to a battery (power source), it will sound a beep and the

Head Lights will be on to illuminate the test area of the probe tip.

Before you test a circuit or component, be sure your tool is in good

order by doing a quick self-test.

With the tool connected, perform a quick self-test. The power switch

is a momentary rocker switch located on the tool’s body. Flanking the

switch are positive and negative markings.

Press the Power Switch forward to activate the tip with a positive

voltage. The Red LED should light and the LCD display will read

the battery voltage. A beep tone will sound. Let go of the power

switch and the LED will turn off and the tone will cease.

2.4 General Description

2.5 Power

2.6 Quick Self-Test

Determine at a glance if a circuit is positive, negative, or open

without having to reconnect clips from one battery pole to another.

Test for continuity with its built-in auxiliary ground lead.

By depressing the power switch, conduct a positive or negative

battery current to the probe tip for testing the function of an

electrical component without the use of jumper wires.

Test for poor ground contacts instantly without performing voltage

drop tests. The tool is also short-circuit protected; its internal

circuit breaker will trip if it becomes overloaded.

Follow and locate short circuits without wasting fuses. The tool’s

long cable allows you to test along the entire length of the

vehicle without constantly searching for suitable vehicle grounds.