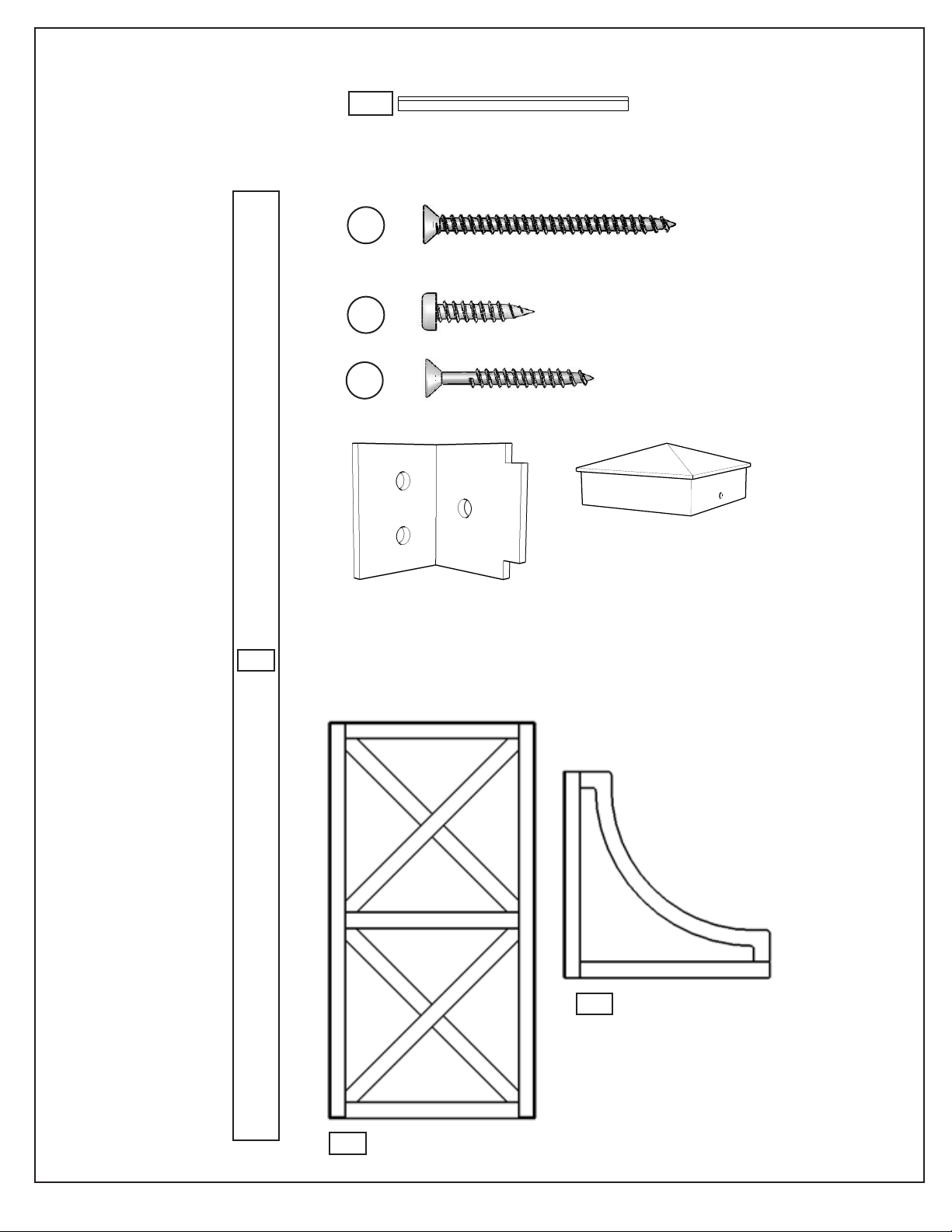

4

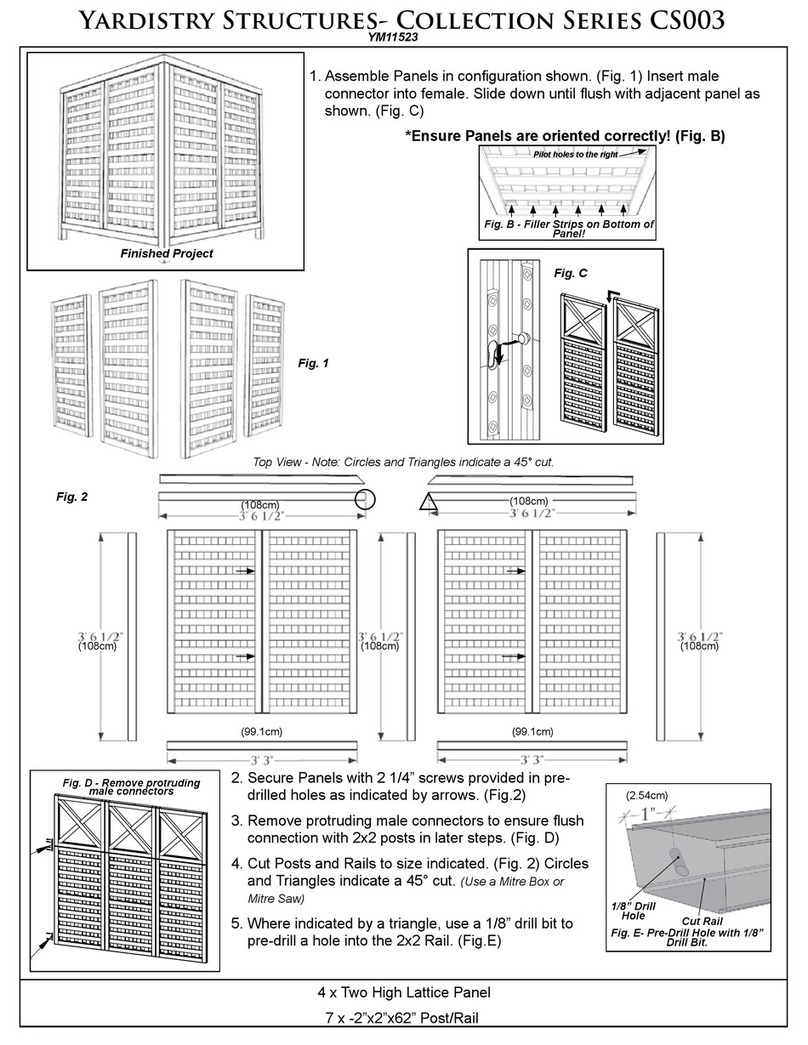

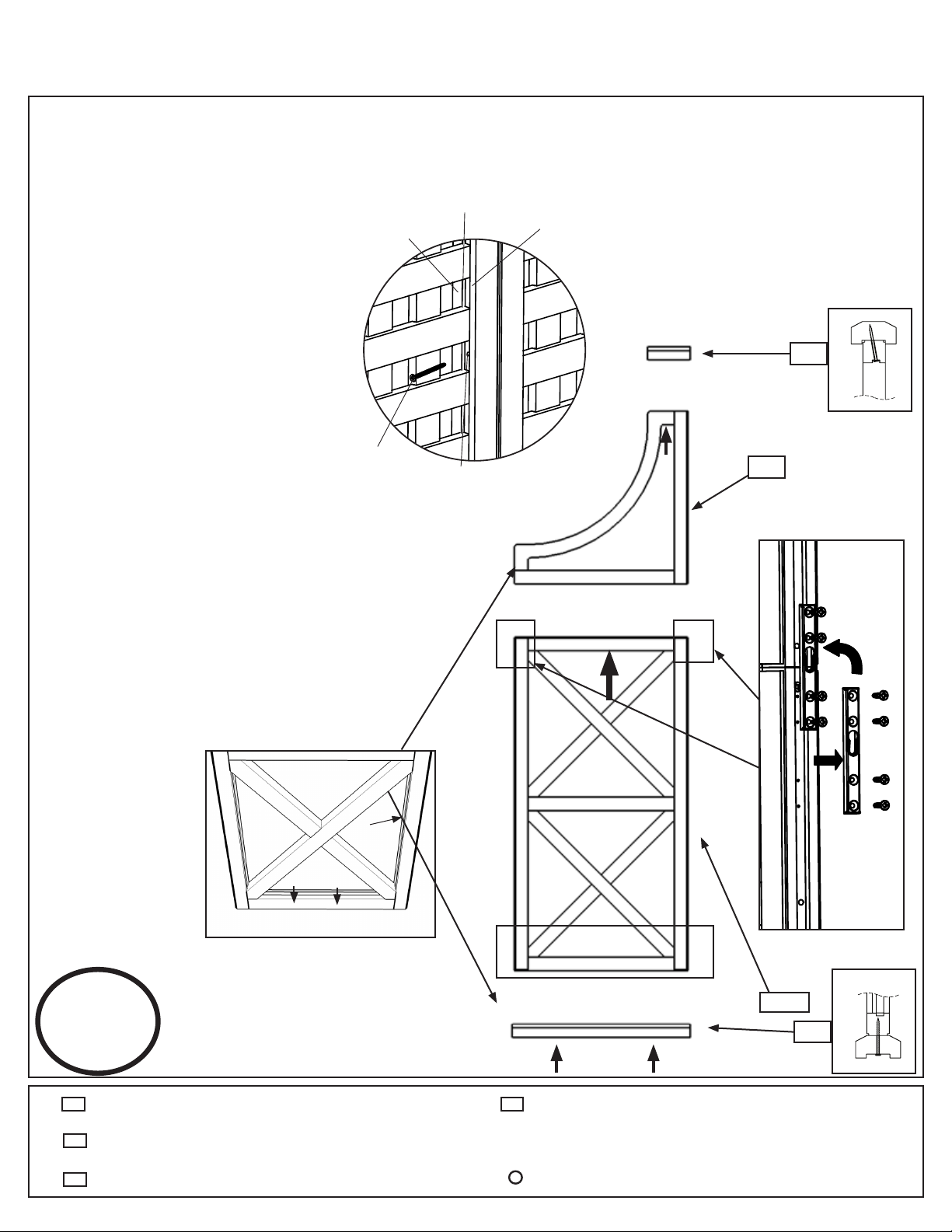

Step 1- Assemble Wings

1.RemovetheuppermetalconnectorsonbothsidesofPX2-TwoHighXPanel.Reattachthemetalconnectors

to PX2 by securing the bottom two holes of the metal connectors to the top two holes on PX2 so that the metal

connectors stick out from the top. Slide PA1 – Arch Topper between the two protruding metal connectors on

the top of PX2. Attach the metal connectors to the factory drilled holes in PA1. (Fig. 1A) *Ensure Panels are

orientedcorrectly!(Fig.1B)

x2

Fig. 1B - Filler Strips on Bottom

of Panel!

2. Secure panels with a S4 - 2

1/4”WoodScrewthelocation

indicated by the large arrow in

the direction of the arrow. When

pre-drilled holes are not available

use a 1/8” Drill Bit to drill holes on

an angle in the inside of the panel

as shown. (Fig. F)

3. Secure R-Top and Bottom Rails to

PanelAssemblywithS4-21/4”

Wood Screws locations indicated

by arrows in the direction of the

arrow. *R- Top and Bottom Rails

will overhang 1/4” on either

sideofpanel.ExceptonArch

Topper!!

* R- Top and Bottom Rails may

need to be cut to 20” (50.8cm)

and 7 1/4” (18.4cm)

(It is recommended to use a Mitre

Box or Mitre Saw)

4. Repeat until two panel assemblies

are created.

R

2x Arch Topper

2x Two High X Panel

2x Top & Bottom Rail At 20” (50.8cm)

2x Top & Bottom Rail At 7 1/4” (18.4cm)

8x #8- 2 1/4” Wood Screws

PA1

PX2

S4

Fig. 1A

Secure with Screws*. Use factory drilled holes.

Asegure el ensamblado usando tornillos*.

Use los agujeros pretaladrados.

Fixez l'assemblage au moyen de vis*. Servez-

vous des trous prépercés à l'usine.

empêche l'accumulation d'eau.

Note wood piece at bottom

prevents collection of water.

Note que la pieza de madera

inferior evita la acumulación de

agua.

Prenez note que la pièce en bois

située au bas de chaque

élément de l'assemblage

Do not remove Small Connector.

No retire los conectores

Ne retirez pas les petites pièces de

raccordement.

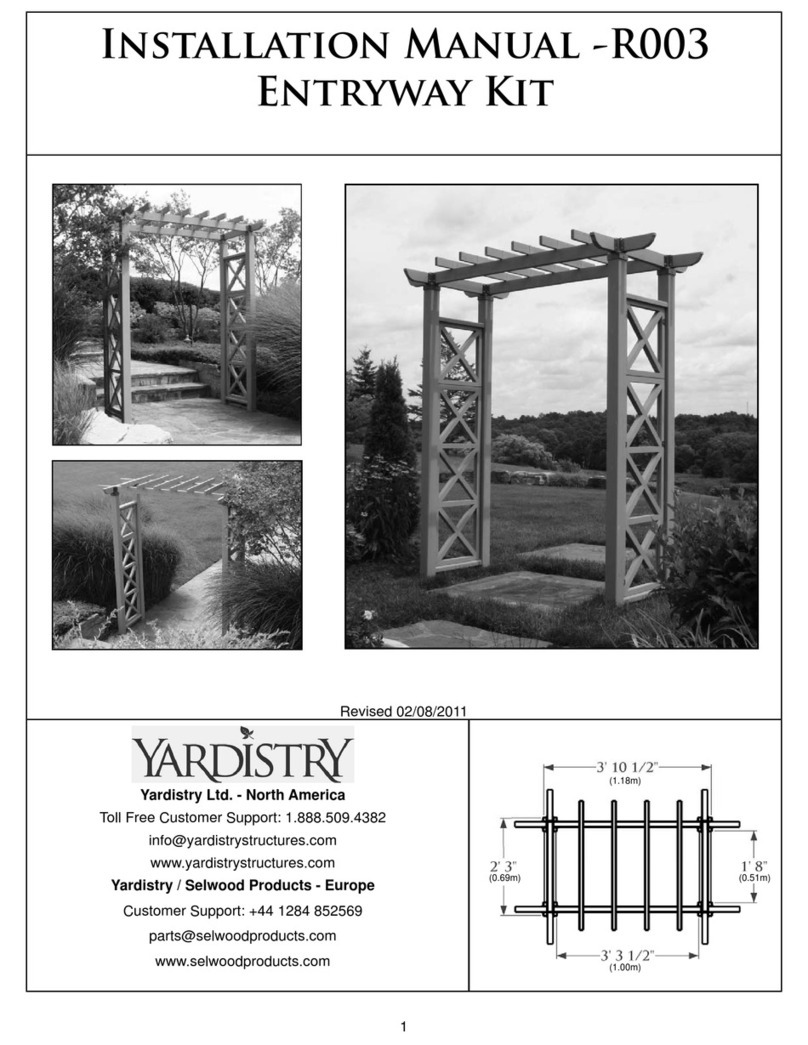

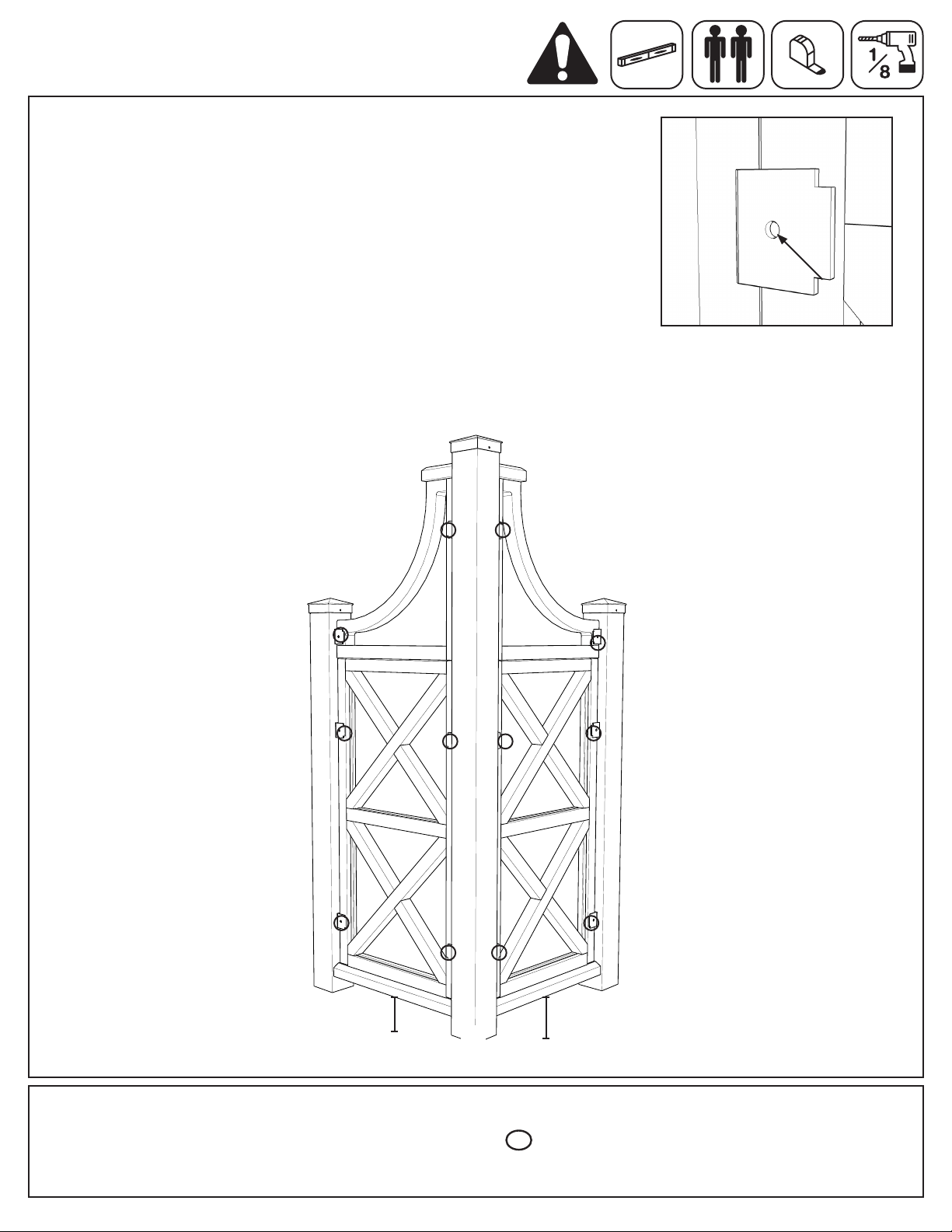

1Assemble Panels in the required orientation for your project.

*Hardware is provided with 2x2x62" post/rail.

Unir los paneles según la orientación necesaria para su proyecto.

l'usine.

supérieurs du panneau qui ont été percés à

A.

fixez-les de nouveau au moyen des deux trous

*Máximo 3 paneles de ancho x 3 paneles de alto.

*Se proporcionan los artículos de ferretería con los postes/travesaños de 2x2x62".

*Maximum 3 panel wide x 3 panel high.

*Le matériel est fourni avec 2x2x62" poste/barre.

*Le maximum 3 panneau x large 3 lambrisent haut.

Assembler Panneau dans l'orientation exigée pour votre projet.

Remove Large Connectors and reattach using

top two factory drilled holes on panel.

Retire los conectores grandes y vuelva a

instalarlos usando los dos agujeros

pretaladrados del panel.

Retirez les grandes pièces de raccordement et

Assemble Toppers to Panels if required.

Instale los topes en los paneles.

Assemblez les pièces supérieures et les panneaux dans l'orientation exigée pour votre projet.

Note orientation of keyhole.

Tenga en cuenta la orientación

del agujero de la cerradura.

Notez l'orientation de l'encoche

en trou deserrure.

PX2

PA1

R

R

3. Connect last assembled panels to make a fence section.

Cut and attach Top and Bottom Rails.

Corte y fije los rieles superior e inferior.

Taillez et fixez la main courante ainsi que la lisse basse.

Insert male into female. Slide down until flush with adjacent panel.

Introduzca el extremo macho en el extremo hembra. Deslícelo hacia

abajo hasta que quede al ras del panel adyacente.

Insérez les pièces de raccordement mâles dans les pièces

de raccordement femelles. Faites glisser le panneau

vers le bas jusqu'à ce qu'il soit au même niveau que

le panneau adjacent.

Remove Large Connectors and reattach using top two

factory drilled holes on panel.

Retire los conectores grandes y vuelva a instalarlos

usando los dos agujeros pretaladrados del panel.

Retirez les grandes pièces de raccordement et fixez-les

de nouveau au moyen des deux trous

supérieurs du panneau qui ont été percés

à l'usine.

Note

orientation

of keyhole.

Tenga en cuenta

la orientación del

agujero de la

cerradura.

Notez l'orientation

de l'encoche en

trou de serrure.

Note que la pieza de madera inferior

evita la acumulación de agua.

Top and Bottom Rail will

overhang 1/4"on either side.

Attach Top with Screws*

through factory drilled holes.

On Bottom, space Screws*

4" from edges of panels.

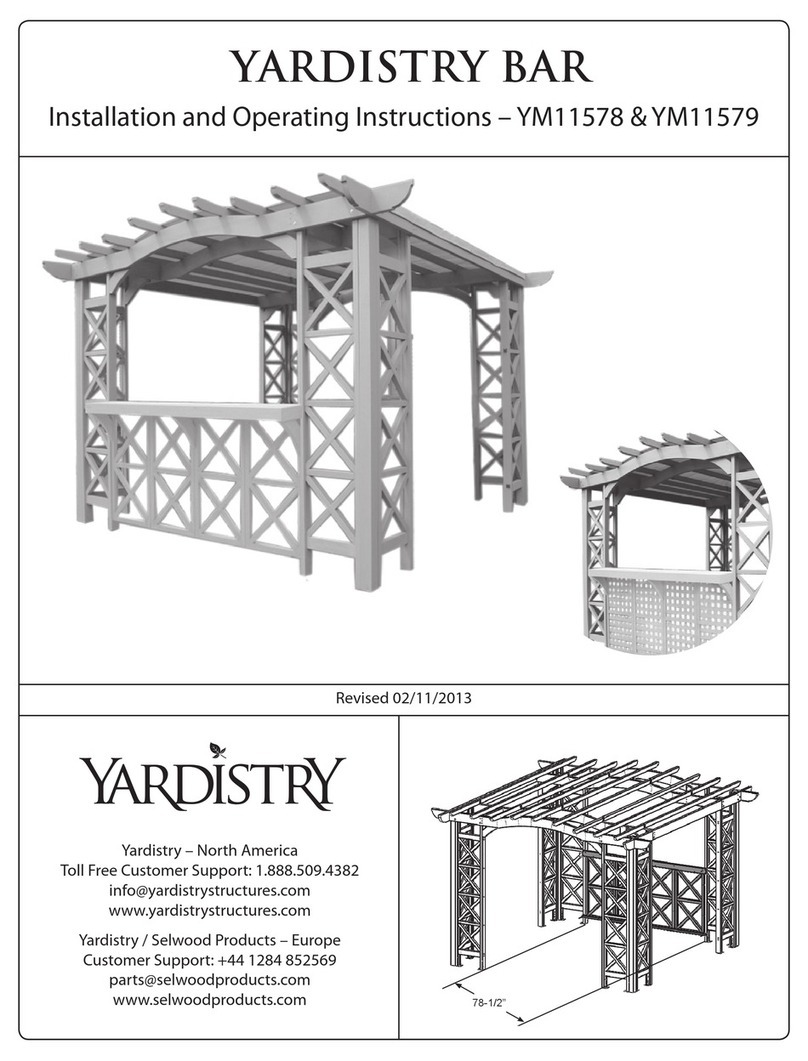

Shown here are configurations using

a Topper. 2 and 3 High Panels can

also be connected together as

purchased.

*Use 2 1/4" stainless steel screws

included in the Panel Clip set to

secure and strengthen the assembly.

78

½"

59"

20" 20" 20" 20"

39

½"

39

½"

One Wide Ancho sencillo Une pièce de largeur

Four Wide Ancho cuádruple Quatre pièces de largeur

Three Wide Ancho triple Trois pièces de largeur

Two Wide Ancho doble Deux pièces de largeur

2

Assemble Panels side by side.

Conecte los paneles lado a lado.

Assemblez les panneaux côte à côte.

No retire los conectores

pequeños.

Note wood piece at bottom prevents

collection of water.

Prenez note que la pièce en bois

située au bas de chaque élément

de l'assemblage empêche

l'accumulation d'eau.

Secure with Screws*. Use factory drilled holes.

Ne retirez pas les petites pièces

de raccordement.

Do not remove Small Connectors.

Fixez l'assemblage au moyen de vis.* Servez-vous des trous prépercés à l'usine.

Asegure el ensamblado usando tornillos*. Use los agujeros pretaladrados.

Screws* are 2 1/4" stainless

steel included in Panel Clip set.

Los tornillos* son de acero inoxidable de 2 1/4"

y se incluyen en el juego de sujetadores de paneles.

*Les vis sont celles de 2-1/4 po en acier inoxydable qui sont fournies dans le nécessaire de fixations pour panneaux.

Basic Guidelines

for Panel Assembly

Las ilustraciones muestran

configuraciones con topes. También

se pueden conectar 2 y 3 paneles

altos a medida que se adquieran.

*Use los tornillos de acero inoxidable

de 2 1/4" que se incluyen en el juego

de sujetadores de paneles para

reforzar el ensamblado.

Pautas básicas para

el ensamblado de

los paneles Les assemblages illustrés comportent des

pièces supérieures. Il est possible

également d'assembler des panneaux

à deux ou à trois carreaux de hauteur

(vendus séparément).

*Utilisez les vis en acier inoxydable de

2-1/4 po fournies dans le nécessaire de

fixations pour panneaux afin de fixer et

de renforcer l'assemblage.

Instructions de base

pour l'assemblage

des panneaux

1Assemble Toppers to Panels.

Instale los topes en los paneles.

Assemblez les pièces supérieures

et les panneaux.

3

Los rieles superior e inferior sobresaldrán 1/4"

a cada lado. Fije el tope instalando tornillos*

en los agujeros pretaladrados. En la parte

inferior, deje un espacio de 4" entre los

tornillos* y los bordes de los paneles.

}

4"

}

4"

}

4"

}

4"

La main courante et la lisse basse seront

en surplomb de 1/4 po de chaque côté.

Fixez la main courante en insérant les vis*

dans les trous prépercés à l'usine. Au bas

des panneaux, laissez un espace de 4 po

entre les vis et les côtés des panneaux.

panel_cap_labels_19x9.5.indd 7 12/3/09 4:17:29 PM

3. Connect last assembled panels to make a fence section.

Cut and attach Top and Bottom Rails.

Corte y fije los rieles superior e inferior.

Taillez et fixez la main courante ainsi que la lisse basse.

Insert male into female. Slide down until flush with adjacent panel.

Introduzca el extremo macho en el extremo hembra. Deslícelo hacia

abajo hasta que quede al ras del panel adyacente.

Insérez les pièces de raccordement mâles dans les pièces

de raccordement femelles. Faites glisser le panneau

vers le bas jusqu'à ce qu'il soit au même niveau que

le panneau adjacent.

Remove Large Connectors and reattach using top two

factory drilled holes on panel.

Retire los conectores grandes y vuelva a instalarlos

usando los dos agujeros pretaladrados del panel.

Retirez les grandes pièces de raccordement et fixez-les

de nouveau au moyen des deux trous

supérieurs du panneau qui ont été percés

à l'usine.

Note

orientation

of keyhole.

Tenga en cuenta

la orientación del

agujero de la

cerradura.

Notez l'orientation

de l'encoche en

trou de serrure.

Note que la pieza de madera inferior

evita la acumulación de agua.

Top and Bottom Rail will

overhang 1/4"on either side.

Attach Top with Screws*

through factory drilled holes.

On Bottom, space Screws*

4" from edges of panels.

Shown here are configurations using

a Topper. 2 and 3 High Panels can

also be connected together as

purchased.

*Use 2 1/4" stainless steel screws

included in the Panel Clip set to

secure and strengthen the assembly.

78

½"

59"

20" 20" 20" 20"

39

½"

39

½"

One Wide Ancho sencillo Une pièce de largeur

Four Wide Ancho cuádruple Quatre pièces de largeur

Three Wide Ancho triple Trois pièces de largeur

Two Wide Ancho doble Deux pièces de largeur

2

Assemble Panels side by side.

Conecte los paneles lado a lado.

Assemblez les panneaux côte à côte.

No retire los conectores

pequeños.

Note wood piece at bottom prevents

collection of water.

Prenez note que la pièce en bois

située au bas de chaque élément

de l'assemblage empêche

l'accumulation d'eau.

Secure with Screws*. Use factory drilled holes.

Ne retirez pas les petites pièces

de raccordement.

Do not remove Small Connectors.

Fixez l'assemblage au moyen de vis.* Servez-vous des trous prépercés à l'usine.

Asegure el ensamblado usando tornillos*. Use los agujeros pretaladrados.

Screws* are 2 1/4" stainless

steel included in Panel Clip set.

Los tornillos* son de acero inoxidable de 2 1/4"

y se incluyen en el juego de sujetadores de paneles.

*Les vis sont celles de 2-1/4 po en acier inoxydable qui sont fournies dans le nécessaire de fixations pour panneaux.

Basic Guidelines

for Panel Assembly

Las ilustraciones muestran

configuraciones con topes. También

se pueden conectar 2 y 3 paneles

altos a medida que se adquieran.

*Use los tornillos de acero inoxidable

de 2 1/4" que se incluyen en el juego

de sujetadores de paneles para

reforzar el ensamblado.

Pautas básicas para

el ensamblado de

los paneles Les assemblages illustrés comportent des

pièces supérieures. Il est possible

également d'assembler des panneaux

à deux ou à trois carreaux de hauteur

(vendus séparément).

*Utilisez les vis en acier inoxydable de

2-1/4 po fournies dans le nécessaire de

fixations pour panneaux afin de fixer et

de renforcer l'assemblage.

Instructions de base

pour l'assemblage

des panneaux

1Assemble Toppers to Panels.

Instale los topes en los paneles.

Assemblez les pièces supérieures

et les panneaux.

3

Los rieles superior e inferior sobresaldrán 1/4"

a cada lado. Fije el tope instalando tornillos*

en los agujeros pretaladrados. En la parte

inferior, deje un espacio de 4" entre los

tornillos* y los bordes de los paneles.

}

4"

}

4"

}

4"

}

4"

La main courante et la lisse basse seront

en surplomb de 1/4 po de chaque côté.

Fixez la main courante en insérant les vis*

dans les trous prépercés à l'usine. Au bas

des panneaux, laissez un espace de 4 po

entre les vis et les côtés des panneaux.

panel_cap_labels_19x9.5.indd 7 12/3/09 4:17:29 PM

R

Pilot holes to the right

B.

niveau que le panneau adjacent.

panneau vers le bas jusqu'à ce qu'il soit au même

pièces de raccordement femelles. Faites glisser le

Assemblez les panneaux côte à côte.

Conecte los paneles lado a lado.

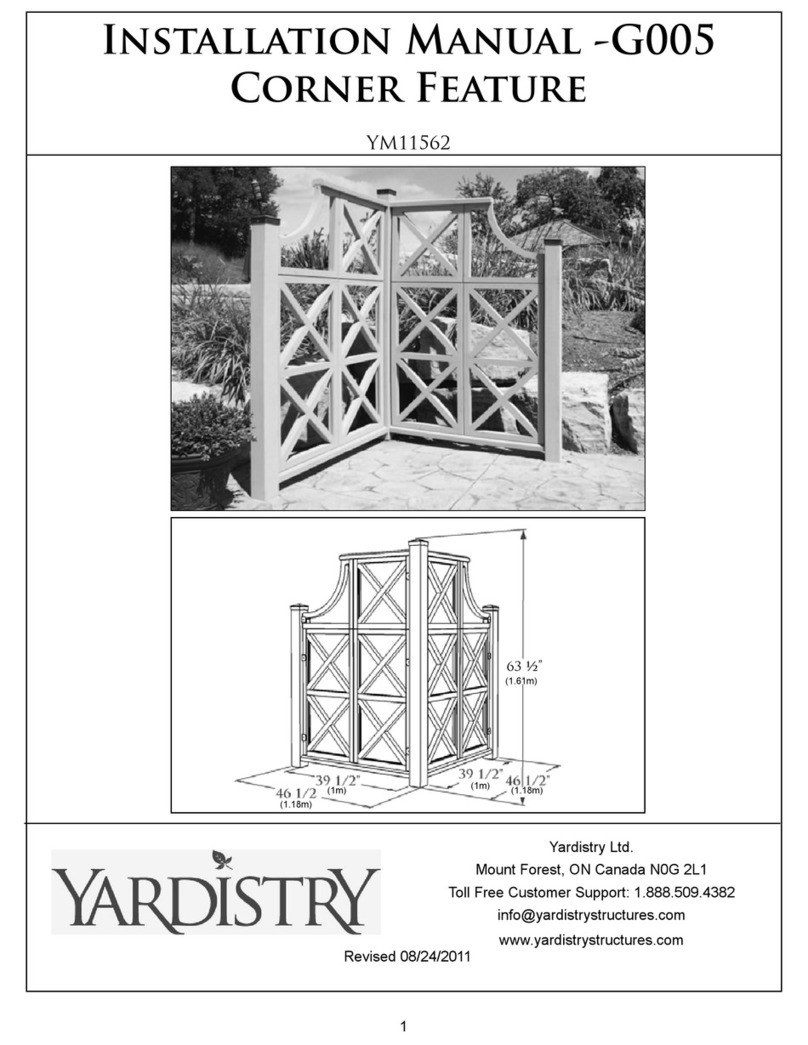

Assemble Panels side by side. (Maximum 3 wide x 3 high)

Insérez les pièces de raccordement mâles dans les

Insert male into female. Slide down until flush with

adjacent panel.

Introduzca el extremo macho en el extremo hembra.

Deslícelo hacia abajo hasta que quede al ras del

panel adyacente.

*Les vis sons 2 1/4po

fourniers avec

poteau/Rail

2 x 2 x 62po.

C.

Screws* are 2 1/4"

included with

2x2x62" post/rail.

*Use los tornillos de

acero inoxidable

de 2 1/4" que se

incluyen en el

juego de

postes/travesaños

de 2x2x62".

Remove the male connectors from the outside of the

panel assembly.

Quite los conectores masculinos del exterior de la

asamblea de panel.

Enlever les connecteurs mâles de l'extérieur de

l'assemblée de panneau.

le connecteur

mâle court

connector

conector

masculino

short male

corto

male

connector

conector

masculino

connecteur

mâle

2 1/4” Screw

Drill Hole on an Angle

Thick Piece

of Wood

Skinny Piece

of Wood

Groove

Fig. F