Table of contents

1 General.................................................................................................................... 4

1.1 Copyright © YASKAWA Europe GmbH............................................................ 4

1.2 About this manual............................................................................................. 5

1.3 Safety information............................................................................................. 6

2 Basics and mounting............................................................................................. 7

2.1 Safety information for users.............................................................................. 7

2.2 System conception........................................................................................... 8

2.2.1 Overview........................................................................................................ 8

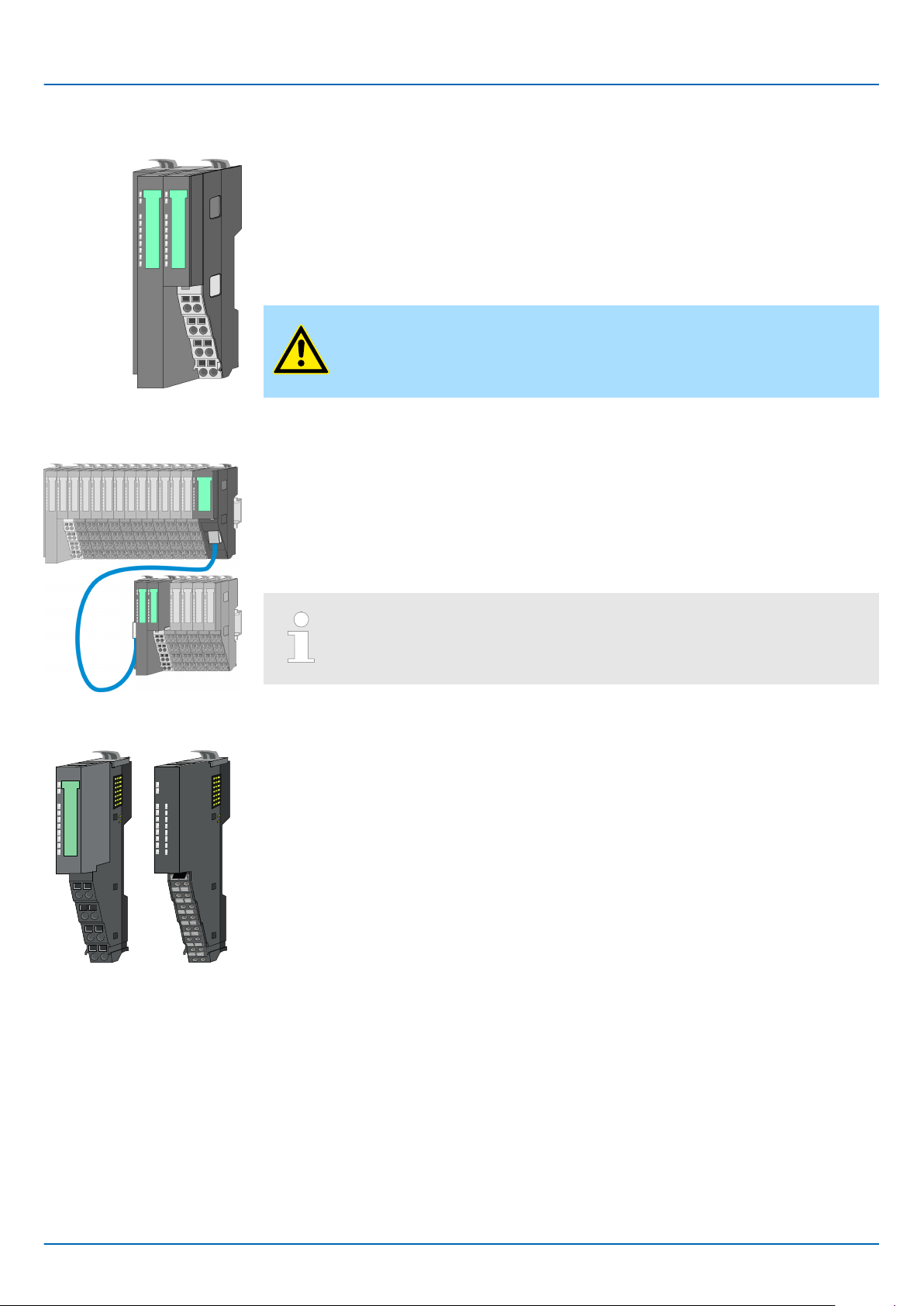

2.2.2 Components.................................................................................................. 9

2.2.3 Accessories................................................................................................. 12

2.2.4 Hardware revision........................................................................................ 14

2.3 Dimensions..................................................................................................... 14

2.4 Mounting 8x periphery modules..................................................................... 17

2.5 Mounting 16x periphery modules................................................................... 20

2.6 Wiring 8x periphery modules.......................................................................... 22

2.7 Wiring 16x periphery modules........................................................................ 24

2.8 Wiring power modules.................................................................................... 25

2.9 Demounting 8x periphery modules................................................................. 29

2.10 Demounting 16x periphery modules............................................................. 32

2.11 Easy Maintenance........................................................................................ 35

2.12 Trouble shooting - LEDs............................................................................... 36

2.13 Installation guidelines................................................................................... 37

2.14 General data for the System SLIO............................................................... 39

3 Hardware description........................................................................................... 41

3.1 Properties....................................................................................................... 41

3.2 Structure......................................................................................................... 41

3.3 Technical data................................................................................................. 44

4 Deployment........................................................................................................... 47

4.1 Fast introduction............................................................................................. 47

4.2 In-/Output area............................................................................................... 49

4.2.1 Input area 12byte ........................................................................................ 49

4.2.2 Output area 4byte ....................................................................................... 50

4.3 Parameter data............................................................................................... 51

4.4 Counter functions........................................................................................... 52

4.5 Diagnostic data............................................................................................... 54

VIPA System SLIO Table of contents

HB300 | FM | 050-1BB30 | en | 20-40 3