8

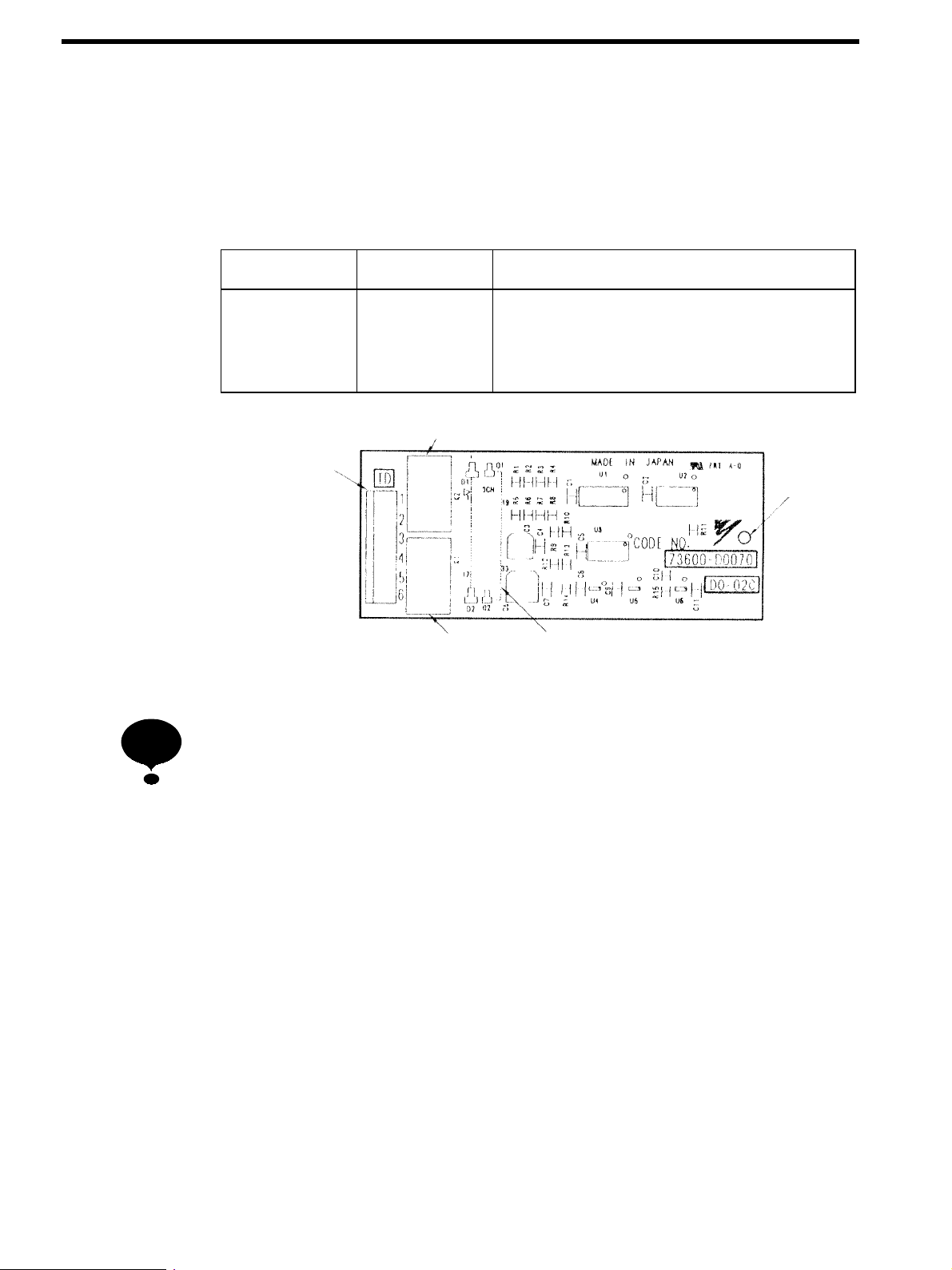

5Related constants for 2C-Relay Output Card DO-02C

Table 2Related constants for 2C-Relay Output Card DO-02C

Operator

function

display

Operator

display

Constant

No. Name Setting

range

Factory

setting

Change

during

operation

Reference

DO-02

Ch1 Select

F5-01 Channel 1 output

selection

0toFF 0 Disabled SRefer to Table 3 for the output func-

tion.

-

DO-02

Ch2 Select

F5-02 Channel 2 output

selection

0toFF 1 Disabled

S

e

er to t

e

unct

on se

ect

on o

t

e

multi-function output terminal of the

inverter for details of each function.

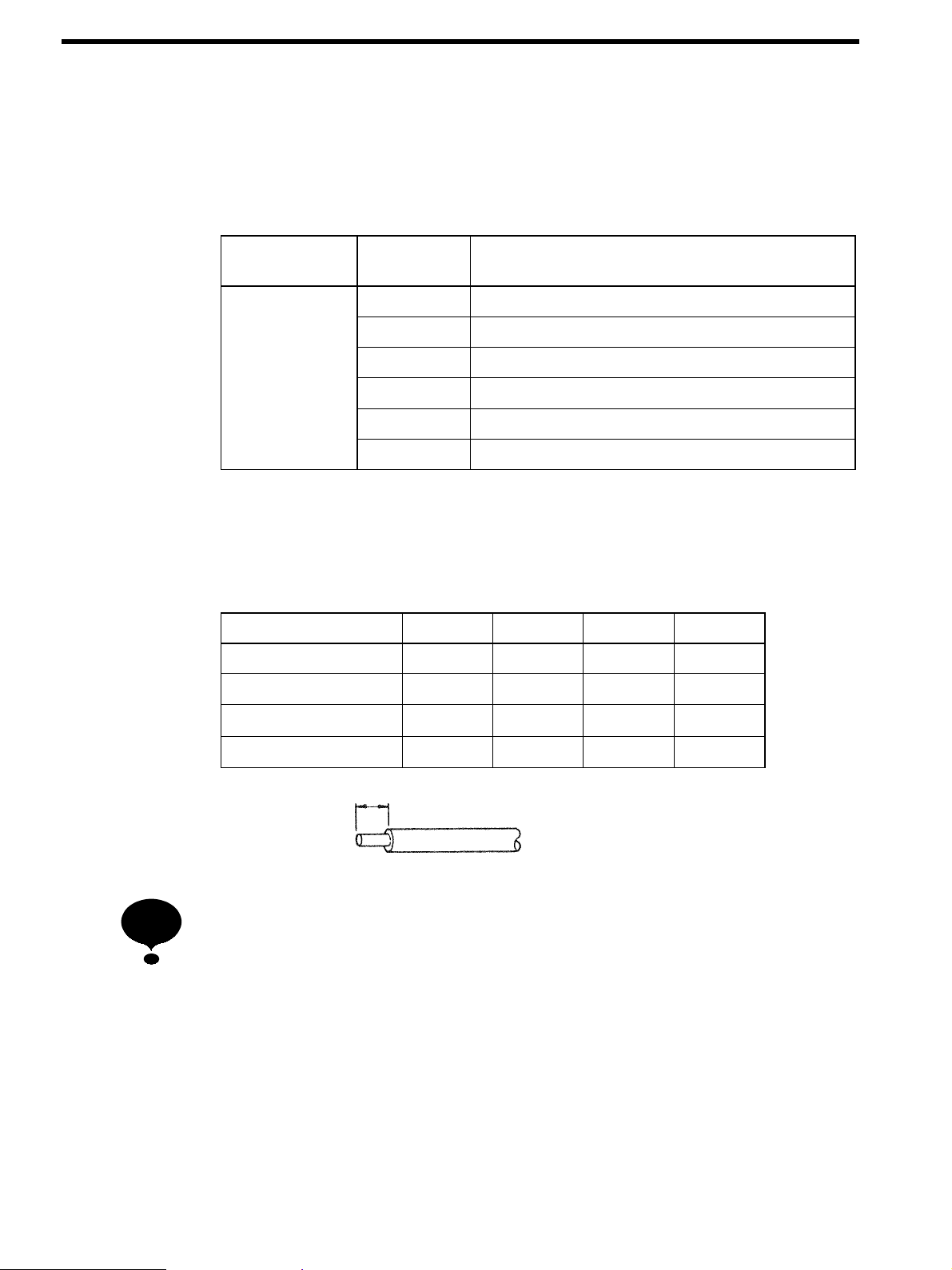

Table 3Multi-function Output Functions of DC-02C

Setting

value Function Setting

value Function

00 During run (ON: run command is input or during in-

verter output)

20 −

01 Zero speed 21 −

02 Frequency agree 1 22 −

03 Desired frequency agree 1 23 −

04 Frequency detection 1 24 −

05 Frequency detection 2 25 −

06 Inverter Operation ready 26 −

07 During undervoltage (UV) detection 27 −

08 During baseblock (NO contact output) 28 −

09 Frequency reference mode 29 −

0A Run command mode 2A −

0B Overtorque detection 1 (NO contact output) 2B −

0C Loss of frequency reference 2C −

0D Braking resistor fault 2D −

0E Fault (Faults other than CPF00 or CPF01) 2E −

0F −2F −

10 Alarm 30 During torque limit *2

11 Fault reset command active 31 During speed limit *1

12 Timer function output 32 −

13 Frequency agree 2 33 During zero-servo *1

14 Desired frequency agree 2 34 −

15 Frequency detection 3 35 −

16 Frequency detection 4 36 −

17 Overtorque detection 1 (NC contact output) 37 During run 2 (Other than Base block, DC injection

braking, initial excitation)

18 Overtorque detection 2 (NO contact output) 38 −

19 Overtorque detection 2 (NC contact output) 39 −

1A During reverse run 3A −

1B During baseblock (NC contact output) 3B −

1C −3C −

1D Regenerating/motoring mode (Closed during regener-

ating mode) *1

3D −

1E Restart enabled 3E −

1F Motor overload (OL1) pre-alarm 3F −

* 1. Can be used during Flux vector control mode.

* 2. Can be used during Open loop vector or Flux vector control mode.