YASKAWA Smart Series User manual

Other YASKAWA Robotics manuals

YASKAWA

YASKAWA motoman NX100 Quick guide

YASKAWA

YASKAWA MOTOMAN DX100 User manual

YASKAWA

YASKAWA MOTOMAN-MH900 User manual

YASKAWA

YASKAWA YR-1-06VX50-A00 Operating instructions

YASKAWA

YASKAWA MOTOMAN-MFL15D-875 User manual

YASKAWA

YASKAWA MH50II Operating instructions

YASKAWA

YASKAWA MOTOMAN-EPX1750 User manual

YASKAWA

YASKAWA Motoman ArcWorld IV-6300 XHD TR3C User guide

YASKAWA

YASKAWA MOTOMAN-SDA20 User manual

YASKAWA

YASKAWA MOTOMAN-ES165D User manual

YASKAWA

YASKAWA MA1440 Operating instructions

YASKAWA

YASKAWA MOTOMAN-MH600 User manual

YASKAWA

YASKAWA MOTOMAN-VS100 User manual

YASKAWA

YASKAWA MOTOMAN-HP20D User manual

YASKAWA

YASKAWA Smart Series Installation and operating instructions

YASKAWA

YASKAWA MOTOMAN MPL80 II User manual

YASKAWA

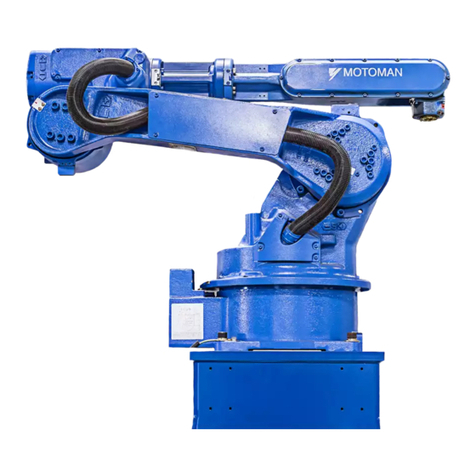

YASKAWA Motoman GP50 User manual

YASKAWA

YASKAWA MH180 Operating instructions

YASKAWA

YASKAWA MOTOMAN-HP6 YR-HP6-A00 User manual

YASKAWA

YASKAWA MOTOMAN-MPX2600 User manual