iii

183574-1CD

183574-1CD

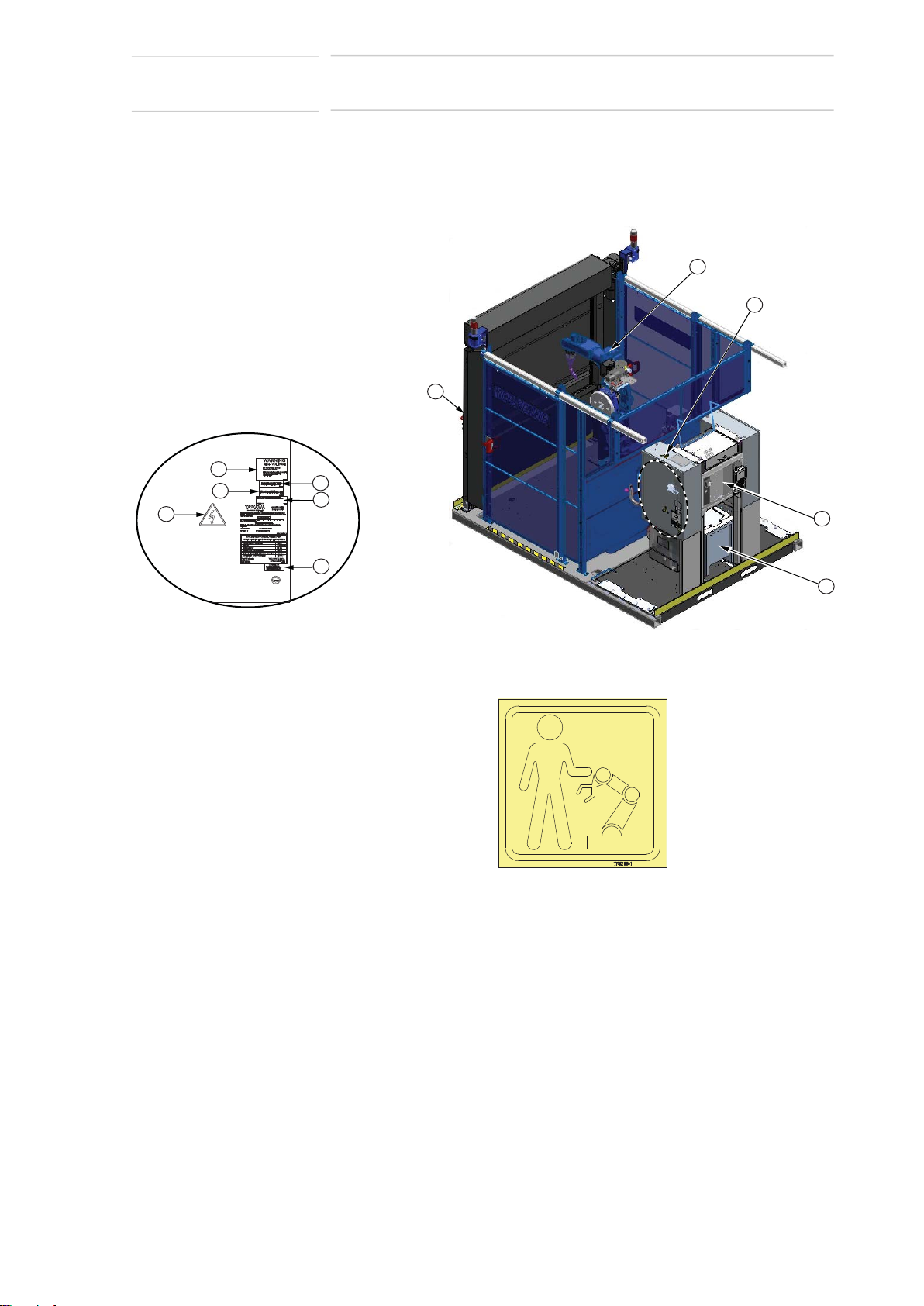

Safety

For Your Safety

ArcWorld 50/50S and 52/

52S

Safety

For Your Safety

Robots generally have requirements which are different from other

manufacturing equipment, such as larger working areas, high-speed

operation, rapid arm movements, etc., which can pose safety hazards.

Read and understand the instruction manuals and related documents, and

observe all precautions in order to avoid the risk of injury to personnel and

damage to equipment.

Carelessness contributes to serious accidents in the work area.

It is the user’s responsibility to ensure that all local, state, and national

codes, regulations, rules, or laws relating to safety and safe operating

conditions are met and followed.

DANGER

• Teaching, operations, and maintenance of the Robot must conform

to:

– Industrial Safety and Health Law

– Order for Enforcement of the Industrial Safety and Health Law

– Industrial Safety and Health Regulations

– Technical Standards for Electrical Facilities

Other related laws and regulations are:

– Occupational Safety and Health Act in USA

– Factory Act (Gewerbeordnung) in Germany

– Health and Safety at Work, etc. Act in UK

– EC Machinery Directive 2006/42/EC

• Prepare:

– SAFETY WORK REGULATIONS

based on concrete policies for safety management complying

with related laws and regulations.

• Observe:

– JIS B 8433-1: 2015 “Robots for industrial environments-Safety

requirements” (ISO 10218-1: 2011) for safe operation of the

robot. (JIS B 8433 is for Japan only)

• Reinforce:

– SAFETY MANAGEMENT SYSTEM

by designating authorized operators and safety managers for the

Robot, as well as giving continuing safety education and training.

• Teaching, operation, and maintenance of the Robot are specified as

“Hazardous Operations” in the Industrial Safety and Health Act (for

Japan only).

Personnel engaged in these operations must receive special

training offered by YASKAWA.