iii

HW0480311

HW0480311

Notes for Safe Operation

Read this manual carefully before installation, operation, maintenance, or inspection of the

MOTOWELD-EH500.

In this manual, the Notes for Safe Operation are classified as “WARNING,” “CAUTION,”

“MANDATORY,” or “PROHIBITED.”

“Serious injury” described above indicates loss of eyesight, injuries, burns (both due to high/

low temperature), electric shock, fractures, poisoning, etc. which may cause personnel to suf-

fer aftereffects, hospitalization, or prolonged out-patient medical treatment.

“Moderate injury” indicates injuries, burns, or electric shock which does not require hospital-

ization or prolonged out-patient medical treatment.

“Damage to equipment” indicates expanded damages relating to property or equipment.

Even items described as “CAUTION” may result in a serious accident in some situations. At

any rate, be sure to follow these important items.

For safe training concerning welding, utilize technical institutes held by the welding society or

association, or related societies or associations, technical courses held by the headquarters

or their branches, or qualifications examinations for welding technicians or engineers.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury to personnel.

Indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury to personnel

and damage to equipment. It may also be used to alert against

unsafe practices.

Always be sure to follow explicitly the items listed under this

heading.

Must never be performed.

To ensure safe and efficient operation at all times, be sure to follow all instructions, even if

not designated as “CAUTION” and “WARNING.”

WARNING

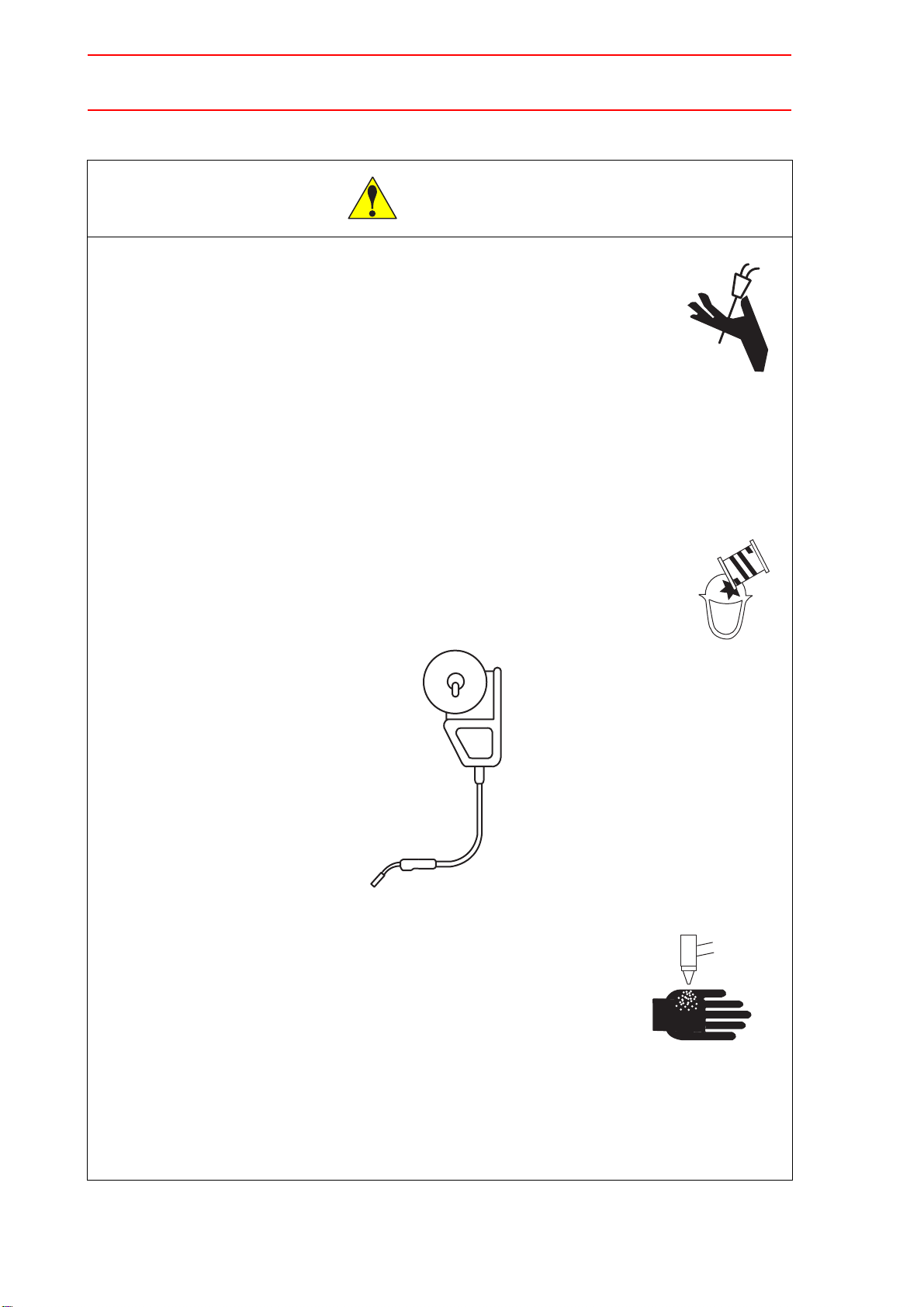

CAUTION

MANDATORY

PROHIBITED

NOTE